Wood fiber processing machinery for large logs

A technology for processing machinery and wood fiber, applied in the field of wood fiber processing machinery, can solve the problems of unsatisfactory processing effect, reduced performance, easy damage to logs, etc., and achieves the effect of superior effect, balanced movement and improved effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

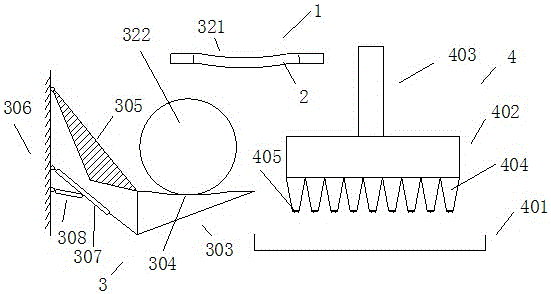

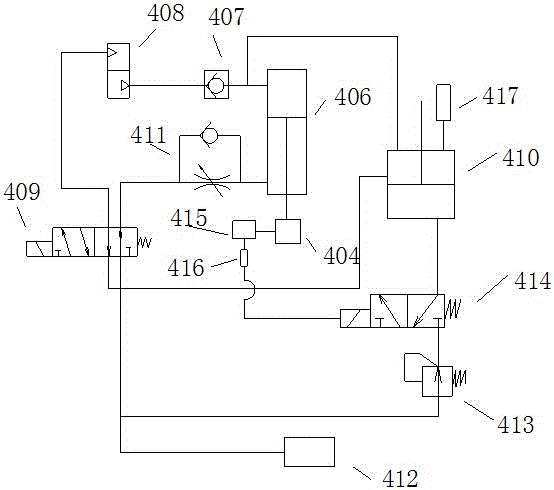

[0018] A wood fiber processing machine for large logs, such as attached figure 1 As shown, the transmission belt 1 is included, and the transmission belt 1 is provided with a drop trough 2, a transmission mechanism 3 is provided below the drop trough 2, and a crushing mechanism 4 is provided beside the transmission mechanism 3;

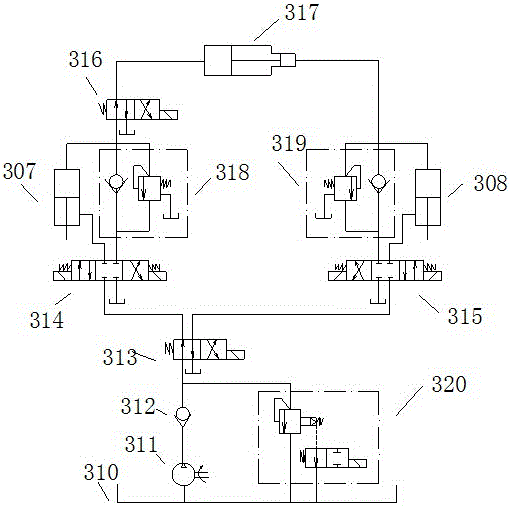

[0019] as attached figure 2 As shown, the transmission mechanism 3 includes a first mechanical part and a first hydraulic part. The first mechanical part includes a lifting platform 303 arranged below the drop tank 2. The surface of the lifting platform 303 is provided with an arc-shaped fixing groove 304. The top corner of the platform 303 is hinged with a support base 305, and the support base 305 is hinged with a fixed block 306; the bottom angle of the lifting platform 303 is connected with a rotating oil cylinder 307, and the bottom of the rotating oil cylinder 307 is hinged with the fixed block 306; The oil cylinder 307 is also connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com