Rim and rubber ring connecting structure of wheel with parallel double tires

A technology of connecting structures and rubber rings, applied in the direction of wheels, wheels, and vehicle parts that can support multiple tires, can solve problems such as affecting the fixing of rubber rings, affecting the service life of tires and rubber rings, etc., to reduce materials and save fuel. Good performance and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

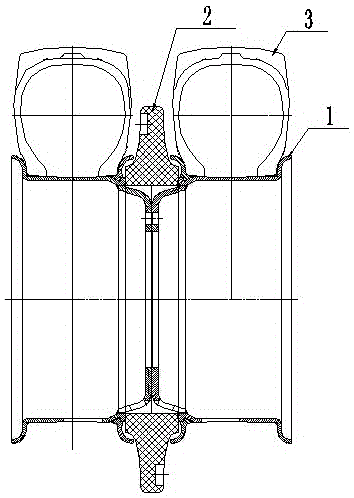

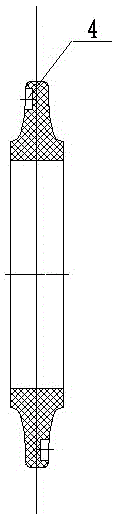

[0016] like figure 1 and figure 2 The connection structure between the rim and the rubber ring of a double-tire parallel-mounted wheel is shown, including the rim 1 of the two tires installed in parallel, and a rubber ring 2 is arranged between the two rims, and the rubber ring is axially aligned with the rim interference fit. The axial interference fit between the rubber ring and the rim does not need to consider the curve forms of different rim webs, so that the rubber ring can be used on rims made by different manufacturers. Realize double positioning and clamping with tire 3 and rim 1. Even if the sidewall position is loose due to the influence of tire pressure during use, the interference fit between the rim body and the rubber ring can also prevent the rubber from moving up and down and protect the tire. The role of the side and the rubber ring. Lightening holes 4 are uniformly arranged on the rubber ring 2 away from the rim. The central axis of the lightening hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com