Packaging bag opening cleaning method

A technology of packaging bag and air suction port, which is applied in the field of bag opening cleaning, can solve the problems of affecting the packaging effect and appearance, bag adhesion and dust packaging, secondary pollution by brushes, etc., and achieves simple structure, low cost, and high efficiency. grade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing:

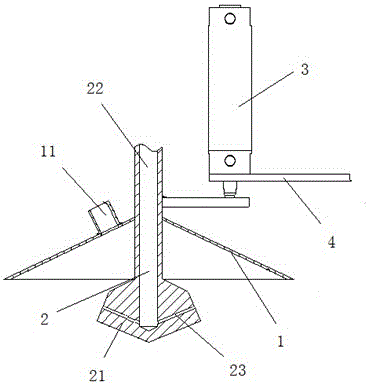

[0009] like figure 1 As shown, the bag opening cleaning mechanism of the present embodiment comprises a dust removal cover 1 whose size matches the bag opening, an air spray head 2 installed in the middle part of the dust removal cover 1 and a telescopic cylinder 3 for driving the air spray head 2 to move back and forth. The head 2 comprises a spray nozzle 21 positioned at the inner side of the dust removal cover 1 and an air nozzle 22 installed on the upper side of the nozzle 21. The peripheral surface of the nozzle 21 is provided with an oblique opening 23. 23 communicates with each other, its air inlet extends to the top of the outer side of the dust removal cover 1, the pipe wall of the dust removal cover 1 and the air injection pipe 22 can be tightly fixed, and the upper side of the dust removal cover 1 is provided with an air suction port 11 communicating with the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com