A film flexible packaging bag

A technology of flexible packaging bags and films, applied in the field of film flexible packaging bags, can solve the problems of unclosable water outlets, no leak-proof function, and easy spillage of liquids, etc., and achieve the effects of convenient storage and transportation, low cost, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

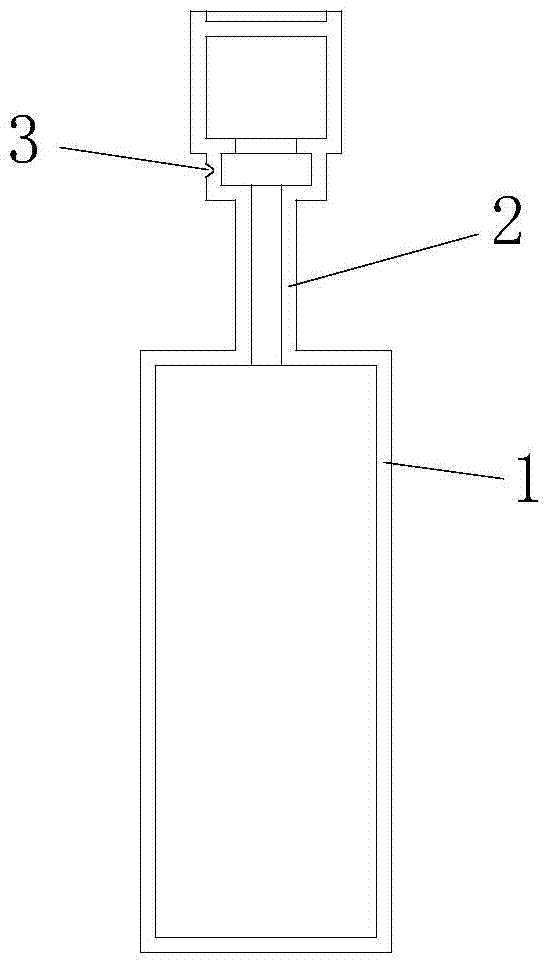

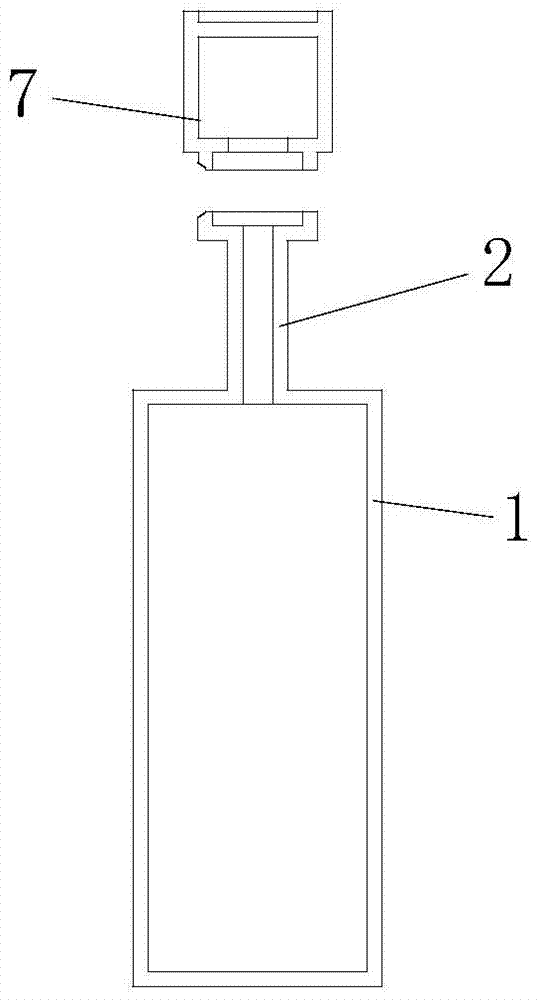

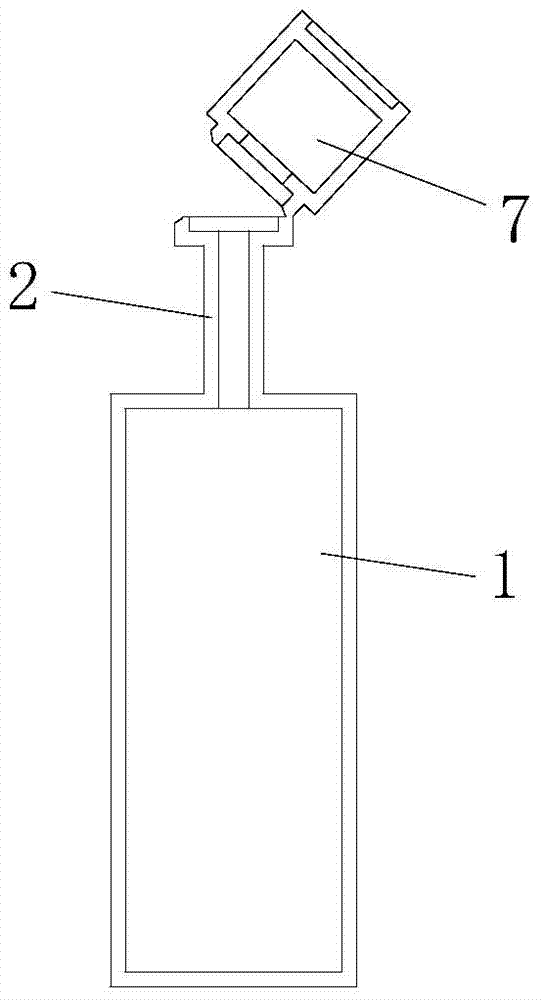

[0059] refer to Figure 1 to Figure 36 , a film flexible packaging bag, formed by hot pressing and cutting of the film, has a bag body 1 and an outlet pipe 2 integrally formed with the bag body 1, the lower end of the outlet pipe 2 communicates with the bag body 1, when making, first The heat sealing line is hot-pressed on the two films at one time, and the two films are welded at the heat sealing line, and then cut along the outside of the heat sealing line to form the bag body 1 and the water outlet pipe 2 at one time, and the width of the bag body 1 is larger than the water outlet pipe 2 width. Due to the hot pressing and cutting process, in terms of shape, the bag body can be made as figure 1 , Figure 8 , Figure 11 , Figure 13 , Figure 15 to Figure 28 and other shapes, the outlet pipe can have a variety of shapes, such as figure 1 As shown, the lower end of the outlet pipe 2 is flush with the edge of the bag body, as Figure 19 , Figure 20 As shown, the bag bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com