Zymomonas mobilis resistant to high-concentration acetic acid and high-concentration furfural and application thereof

A technology of Zymomonas and movement, which is applied in the field of microorganisms, can solve the problem that it is difficult to tolerate high concentrations of acetic acid and high concentrations of furan formaldehyde at the same time, and achieve the effect of saving detoxification treatment steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0026] This preparation example is used to illustrate the preparation of RM medium containing acetic acid and furan formaldehyde, and the process of preparing an enzymatic hydrolyzate from a cellulose-containing raw material (corn stalk).

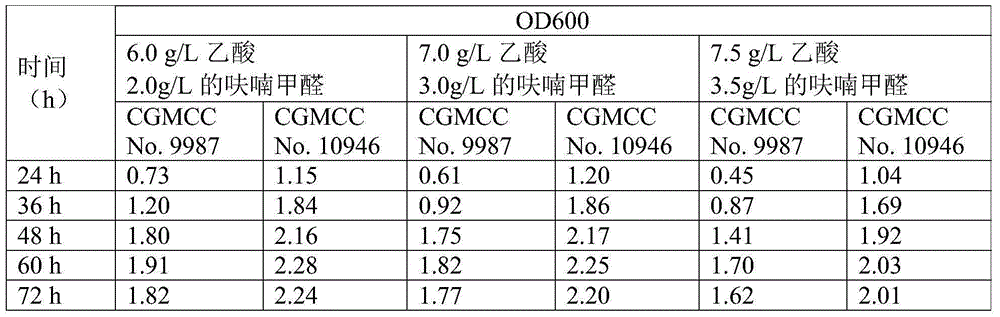

[0027] According to 20.0g / L glucose, 10.0g / L yeast powder, 1.0g / LMgCl 2 , 1.0g / L (NH 4 ) 2 SO 4 and 1.0g / LKH 2 PO 4 The formulation configuration of the base RM medium was obtained. Add acetic acid and furfuralaldehyde to the basic RM medium to obtain 3 kinds of RM adjusted medium, wherein, the first RM adjusted medium contains 6.0g / L acetic acid and 2.0g / L furfuralaldehyde, and the second RM adjusted medium Containing 7.0 g / L of acetic acid and 3.0 g / L of furfuraldehyde, the third RM conditioned medium contained 7.5 g / L of acetic acid and 3.5 g / L of furfuraldehyde.

[0028] Cut the corn stalks into small pieces of about 2 cm, then add water to adjust the water content to 40% by weight; transport them to the heat preservation pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com