Treatment method of settlement of high-speed railway roadbeds in soft-soil areas

A high-speed railway and roadbed technology, applied in the field of geotechnical engineering, can solve the problems of grouting amount, improper control of grouting pressure parameters, long time for grouting slurry to reach expected strength, adverse effects on roadbed structure and surrounding environment, etc. Subgrade settlement, low cost, and the effect of compensating settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

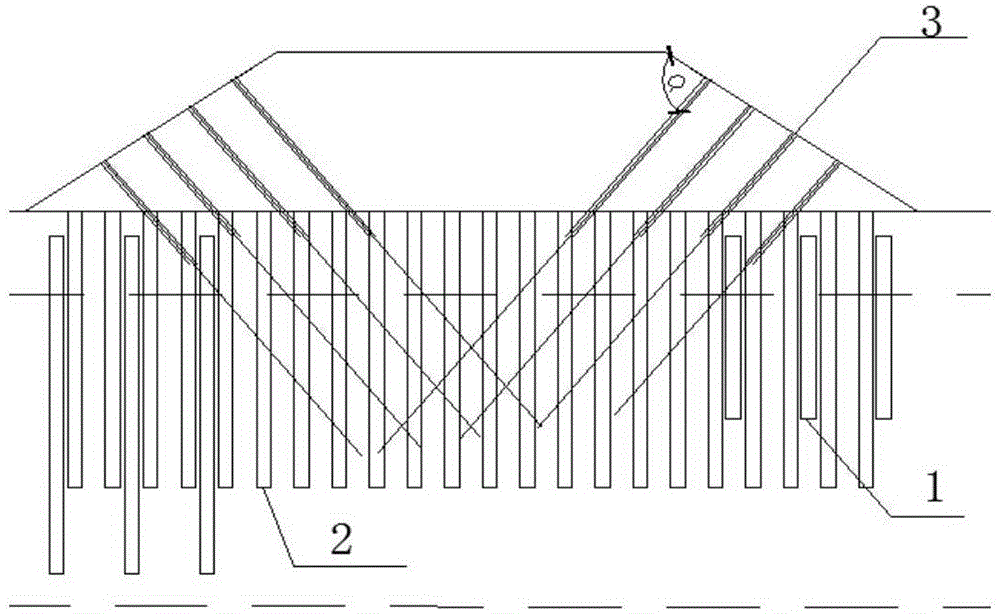

[0032] The foundation of a certain high-speed railway was originally designed to be reinforced with grout-sprayed piles. The diameter of the grout-sprayed piles is 0.5m, the pile spacing is 1.3m, and the piles are arranged in an equilateral triangle. The pile length is 10-19.5m, and the reinforcement effect is not ideal. Now apply the present invention to carry out high-speed railway embankment settlement regulation, specifically comprise the following steps:

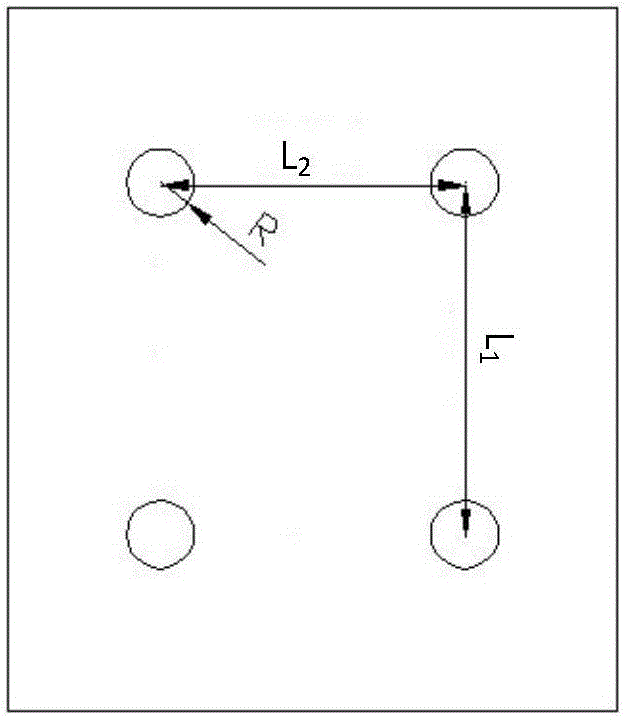

[0033] Step 1: The gap between the original pile foundation 2 grout sprayed piles that have been constructed at the toe of the subgrade slope is reinforced with rotary grouted pile 1. image 3 It is a schematic diagram of the rectangular arrangement of jet-grouting piles in the method for subgrade settlement improvement of high-speed railway in soft soil area according to the embodiment of the present invention, wherein the diameter of the jet-grouting piles is 0.5m, the pile length is 10.0-22.0m, and the horizontal dist...

Embodiment 2

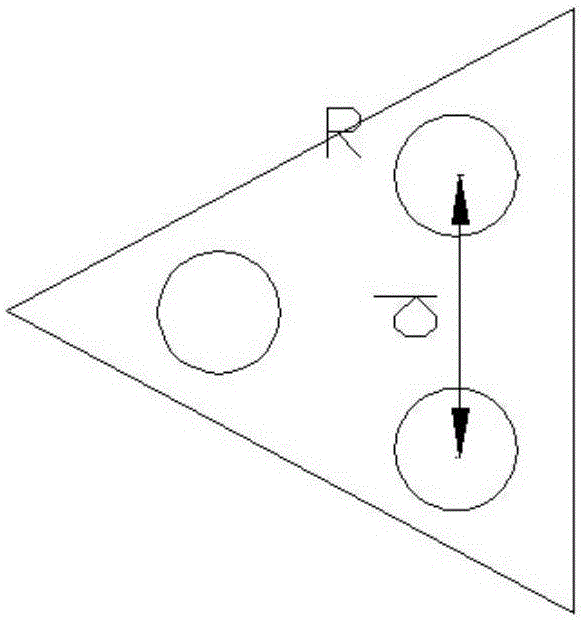

[0043] The difference from Example 1 is that the layout of the jet grouting piles adopts an equilateral triangle, such as figure 2 as shown, figure 2 It is a schematic diagram of the triangular arrangement of jet grouting piles in the method for subsidence control of high-speed railway subgrade in soft soil area according to the embodiment of the present invention. Now apply the present invention to carry out high-speed railway embankment settlement regulation, specifically comprise the following steps:

[0044] Step 1: The gap between the original pile foundation 2 grout sprayed piles that have been constructed at the toe of the subgrade slope is reinforced with rotary grouted pile 1. The pile diameter of the jet grouting pile is 0.5m, the radius R of the jet grouting pile is 0.25m, the length of the pile on the left side of the subgrade is 12.22m, and the length of the pile on the right side is 6.6m.

[0045]Step 2: After the rotary grouting pile reaches the design stren...

Embodiment 3

[0054] The difference from Embodiment 1 and Embodiment 2 is that the subgrade height of a certain section of a high-speed railway is low, and it is not suitable to arrange the grouting flower pipe 3 on the roadbed slope, so the grouting flower pipe 3 is arranged on the ground, such as Figure 4 as shown, Figure 4 It is a schematic diagram of the grouting flower tube on the ground in the method for subsidence control of high-speed railway subgrade in soft soil area according to the embodiment of the present invention. Now apply the present invention to carry out high-speed railway embankment settlement regulation, specifically comprise the following steps:

[0055] Step 1: The gap between the original pile foundation 2 that has been constructed at the slope toe of the subgrade is reinforced with rotary grouting pile 1. Among them, the diameter of the rotary grouting pile is 0.5m, the pile length is 10.0-22.0m, and the horizontal distance between piles is 2.6 m, 3 columns unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com