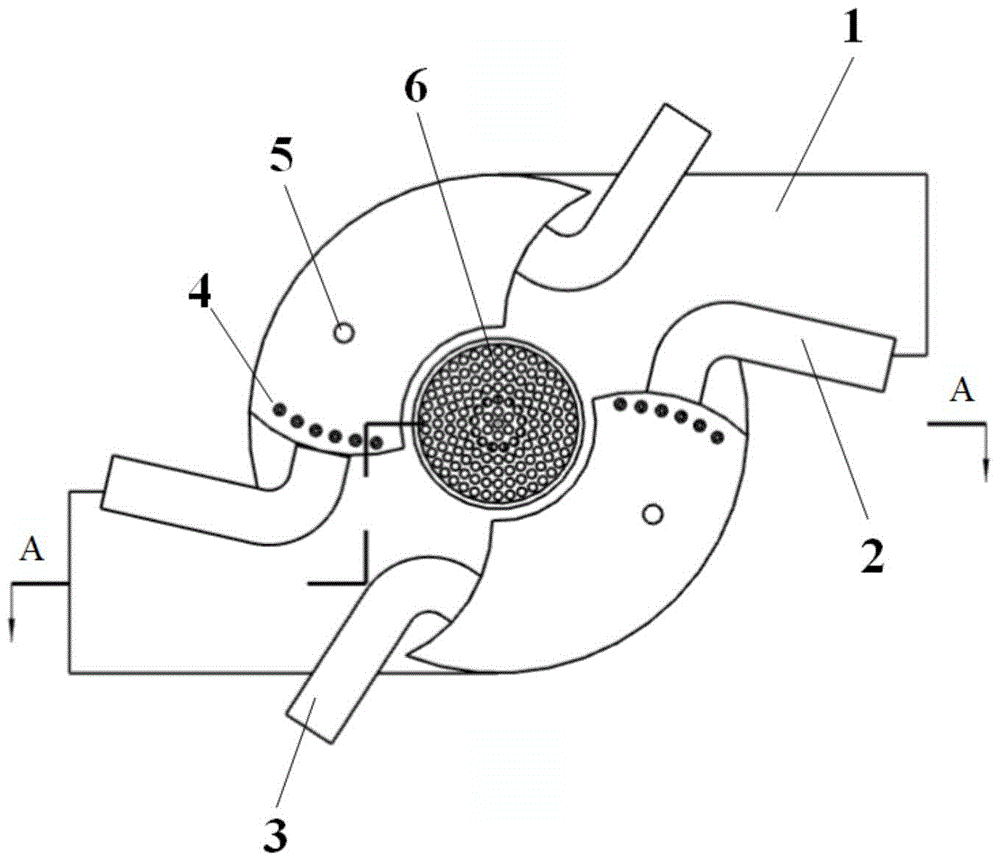

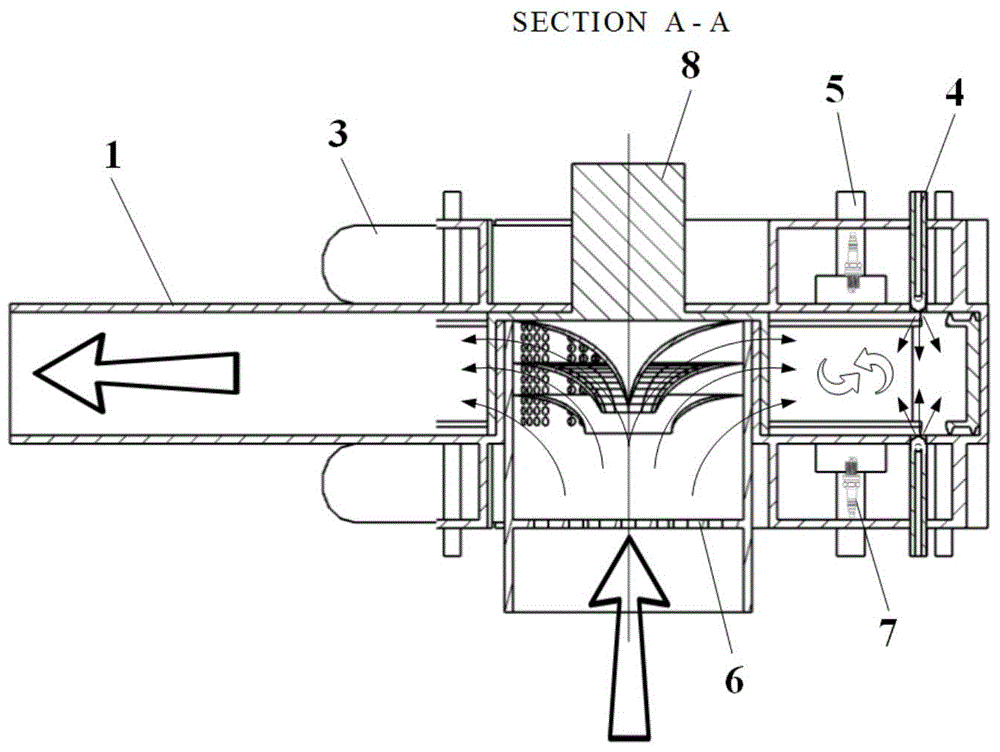

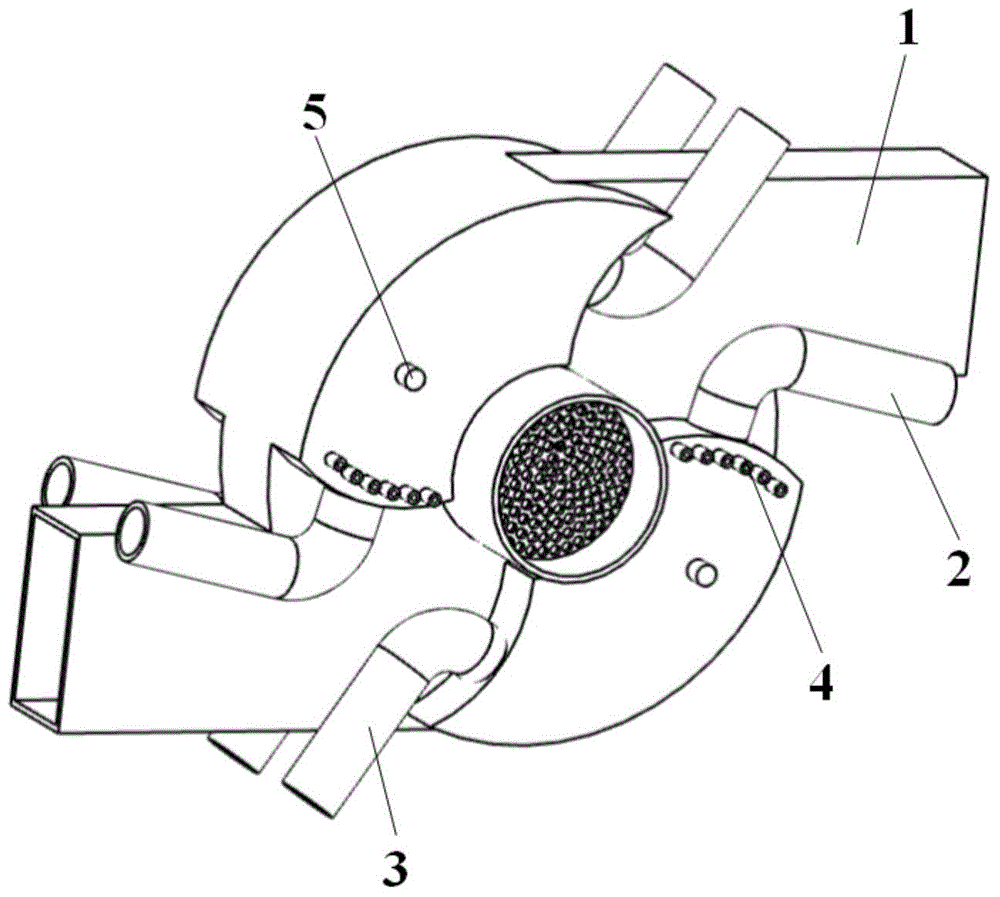

Rotary constant-volume pressurizing combustion chamber

A combustion chamber and isovolume technology, applied in the field of combustion chambers, can solve the problems that the effective volume of the combustion chamber is less than the volume of the combustion chamber, the limited flow of air and fuel in the combustion chamber, etc., to achieve continuous intake and exhaust, and mechanical friction. The effect of reducing losses and shortening the premix distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] In the present embodiment, the diameter of the inner cavity of the combustion chamber shell 11 is 250 mm, and the wall thickness is 4 mm; the length of the inner cavity of the square tube-shaped combustion chamber exhaust structure 12 tangent to the combustion chamber shell 11 is 87 mm, the width is 44 mm, and the wall thickness is 4 mm; The heater 9 is arranged on both sides of the combustion chamber shell 11, the radius of the inner arc side is 50 mm, the radius of the outer arc side is 128 mm, and the width is 30 mm. The inlet and outlet ends of the fuel preheater 9 are designed to be convex and concave respectively. shape; the inner diameter of the fuel inlet pipe 2 and the fuel outlet pipe 3 is 26mm, in order to prevent the fuel pipes from intersecting, the fuel inlet pipe 2 and the fuel outlet pipe 3 are respectively connected to the intake end of the fuel preheater 9 and the fuel outlet pipe 3 through a 90-degree turn. The gas outlet is connected; a plurality of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com