Experimental device for evaluating external pressure resisting intensity of anti-sand sieve tube

A technology of sand control screen and experimental device, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., which can solve the problem of unfavorable selection of sand control screen and improvement of service life of sand control screen. Oil well economic indicators, unconsidered Sand control screen output and sand output and other issues, to achieve the effect of true test results, low cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

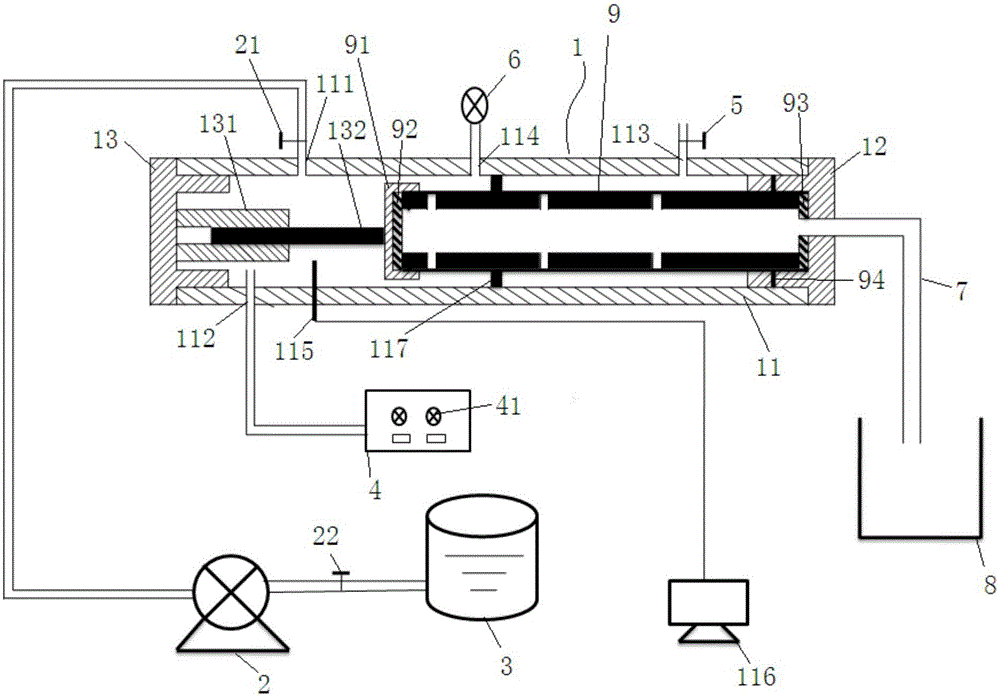

[0016] Such as figure 1 As shown, the experimental device for evaluating the anti-extrusion strength of the sand control screen of the present invention comprises an autoclave 1, a water injection pump 2, a water storage tank 3, a high pressure pump 4, a pressure relief valve 5, a pressure gauge 6, A drainage pipe 7 and a liquid receiving pool 8; the autoclave 1 includes an autoclave body 11, a first sealing cover 12 and a second sealing cover 13; Tubular structure, the autoclave body 11 is provided with a water injection through hole 111, a pressurization through hole 112, a pressure relief through hole 113 and a pressure monitoring through hole 114 that communicate with the interior of the autoclave body 11; the water injection through hole 111 is connected by a pipeline The water outlet of the water injection pump 2, the water inlet of the water i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com