Detection device for transverse cracks and longitudinal cracks of glass bottle opening

A detection device and crack detection technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of inconvenient detection methods for measuring bottle mouth cracks, incapable of real-time detection of bottles, and inability to accurately measure bottle mouths, etc. To achieve the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

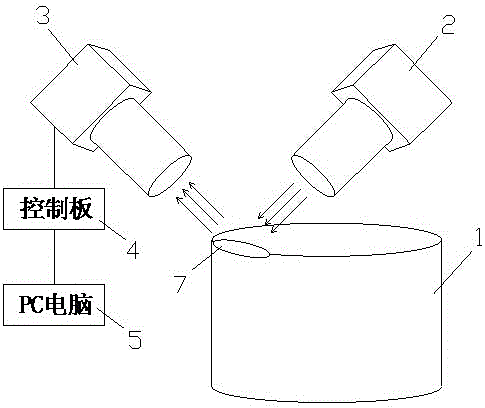

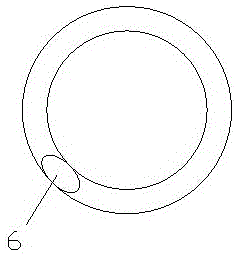

[0021] Such as Figure 1-Figure 3 As shown, a glass bottle mouth transverse crack detection device includes a bottle mouth 1, an LED light source 2 and a crack detection head 3, the LED light source 2 and the crack detection head 3 are all located above the bottle mouth 1, and the crack detection head 3 is a high-speed photodiode, the crack detection head 3 is connected with a control board 4, and the control board 4 is connected with a PC computer 5, and the light emitted by the LED light source 2 forms a light spot 6 on the bottle mouth 1 at a 90° angle. Angular reflection to the crack detection head 3, the light spot 6 is a strip-shaped light spot, the length of the strip-shaped light spot is 1cm, and the width is 2mm. The LED light source 2 is provided with a focusing lens (not shown). The incident angle of the LED light source 2 is 0-90°.

Embodiment 2

[0023] Such as Figure 3-4 As shown, a glass bottle mouth longitudinal crack detection device includes a bottle mouth 1, an LED light source 2 and a crack detection head 3, the LED light source 2 and the crack detection head 3 are all located on the side of the bottle mouth 1 circumference, and the crack detection The head 3 is a high-speed photodiode, and the crack detection head 3 is connected with a control board 4, and the control board 4 is connected with a PC computer 5, and the light emitted by the LED light source 2 forms a light spot 6 on the bottle mouth 1, and has a 90° angle. ° angle is reflected in the crack detection head 3, the light spot 6 is a strip light spot, the length of the strip light spot is 1cm, and the width is 2mm, the LED light source 2 is provided with a focusing lens, and the LED light source 2 The incident angle is 0-90°.

[0024] The beneficial effect of the present invention is: through the principle of light reflection, the LED light source i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com