Electrified oiling device for distribution transformer

A technology for distribution transformers and refueling devices, applied in transformer/inductor cooling, measuring devices, instruments, etc., can solve problems such as equipment loss, equipment airtightness and insulation degradation, and burnt transformers, reducing and improving the probability of failure Benefits of electricity sales and the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

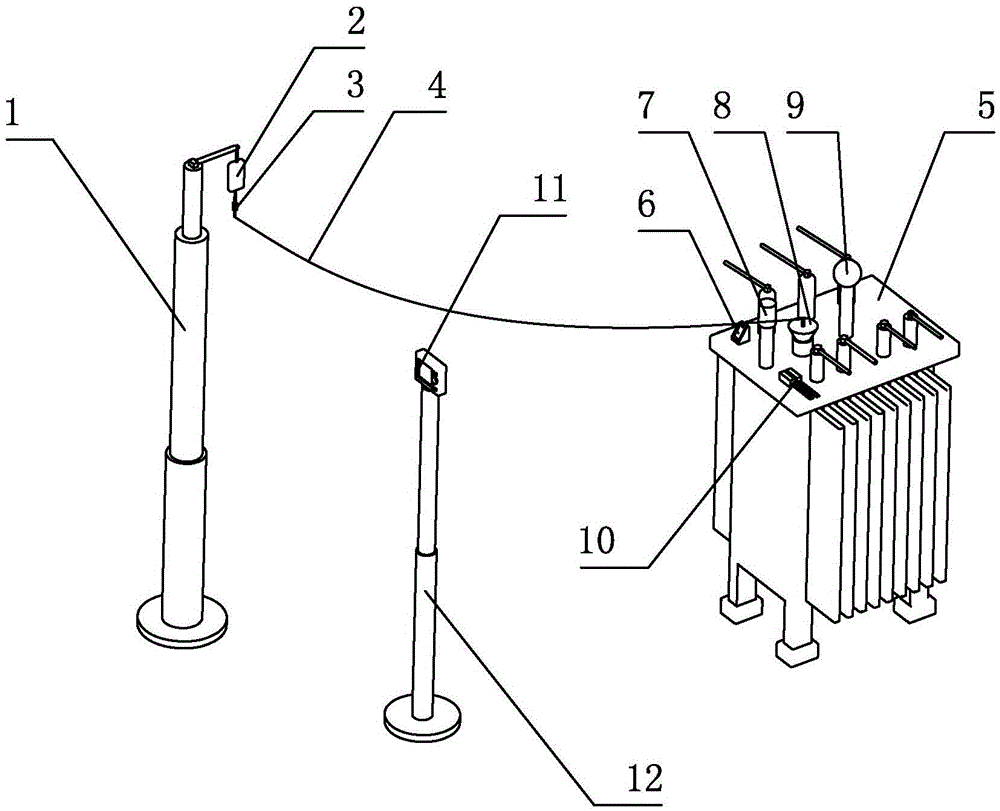

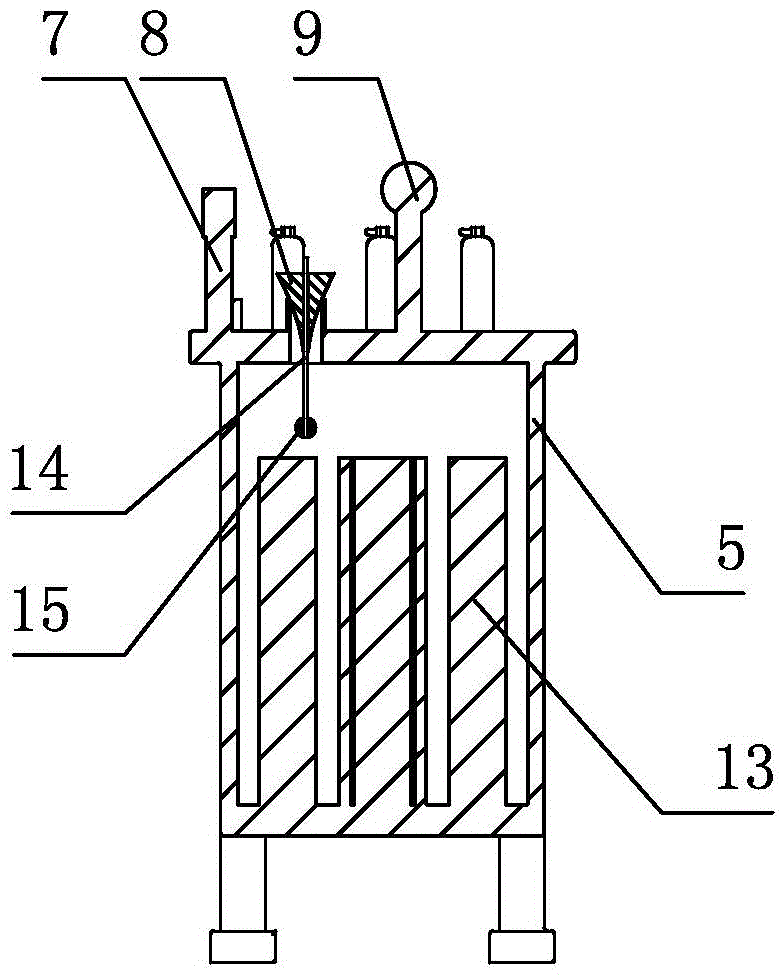

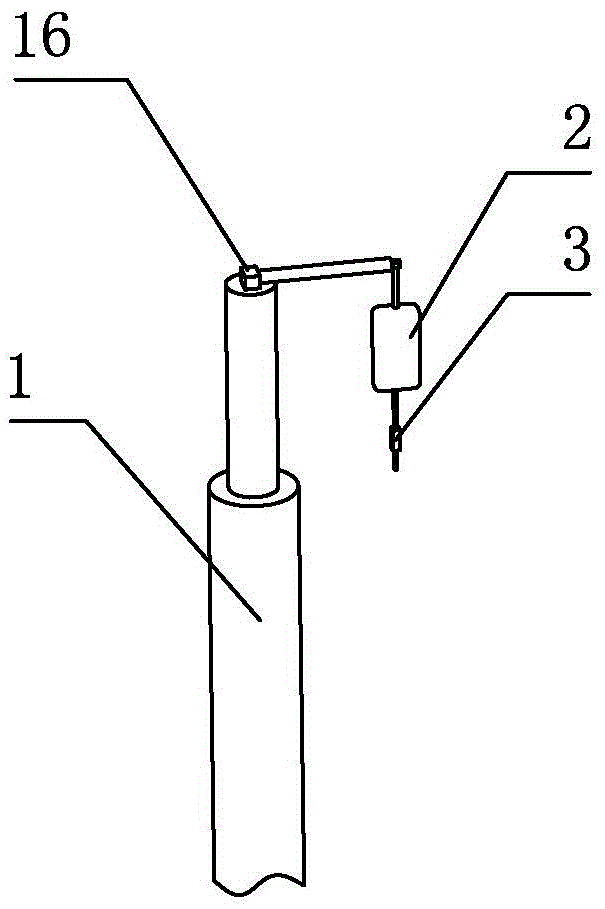

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as Figure 1~3 As shown, the distribution transformer live refueling device includes a first support 1, a second support 12 and a through-hole cone 8 that can be placed at the oil filling port of the transformer 5. The through-hole cone 8 is an inverted conical shape, and the through-hole cone 8 is inclined. There is an exhaust groove, and the through-hole cone 8 is made of PTFE material. After the cover on the oil injection hole is removed, the through-hole cone 8 can ensure that dust cannot enter the transformer 5. At the same time, the through-hole cone 8 can be used as a support for the insulating flexible oil pipe 4 thing, prevent the insulating flexible oil pipe 4 from contacting the transformer 5 shell of the ground potential. Hollow oil pipe 14 is arranged in the center of through-hole cone 8, and the scale is marked on hollow oil pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com