Steel sheet and method for producing same

A steel plate and steel slab technology, applied in the field of steel plate preparation, can solve problems such as aging, lower steel quality, and surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

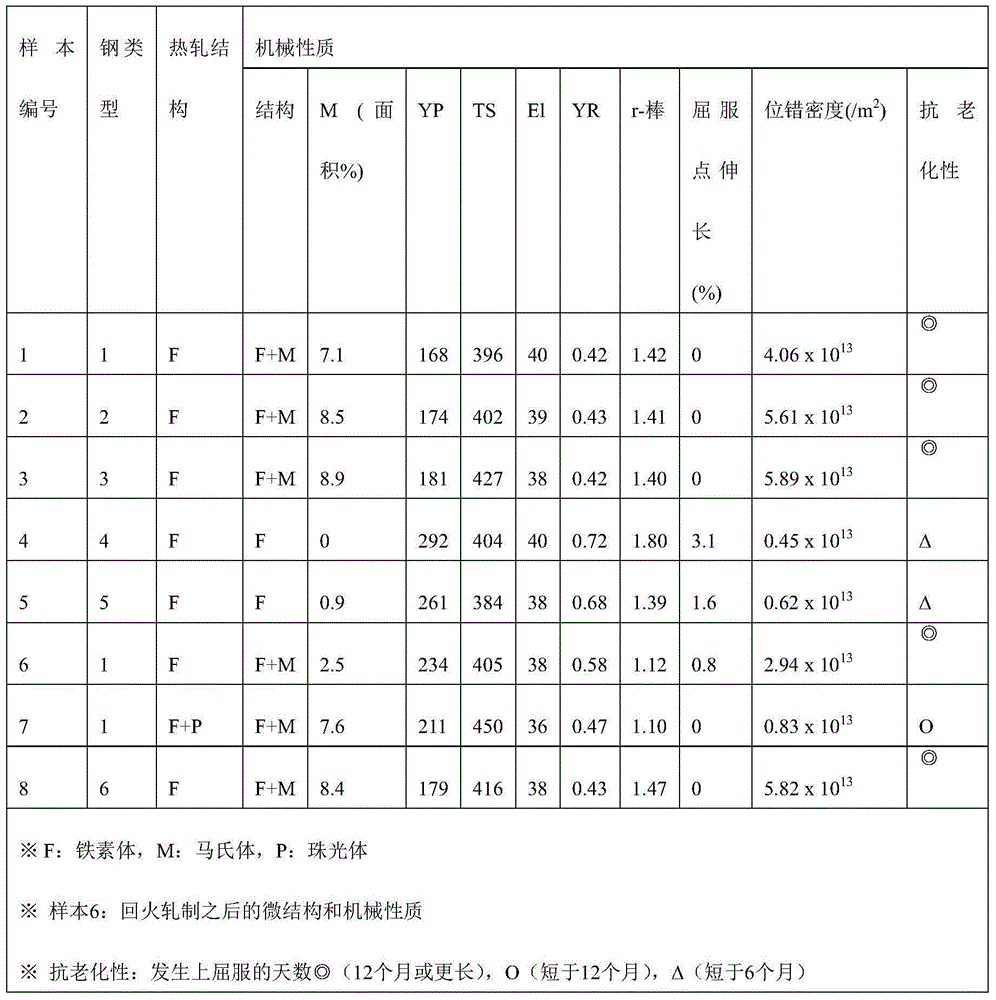

[0083] Hereinafter, the structure and effects of the present invention will be described in further detail with reference to preferred embodiments. It should be understood, however, that these examples are for illustrative purposes only and are not intended to limit the scope of the invention in any way. Those skilled in the art can easily conceive of matters not described herein, and thus a detailed description thereof is omitted.

[0084] 1. Preparation of steel plate samples

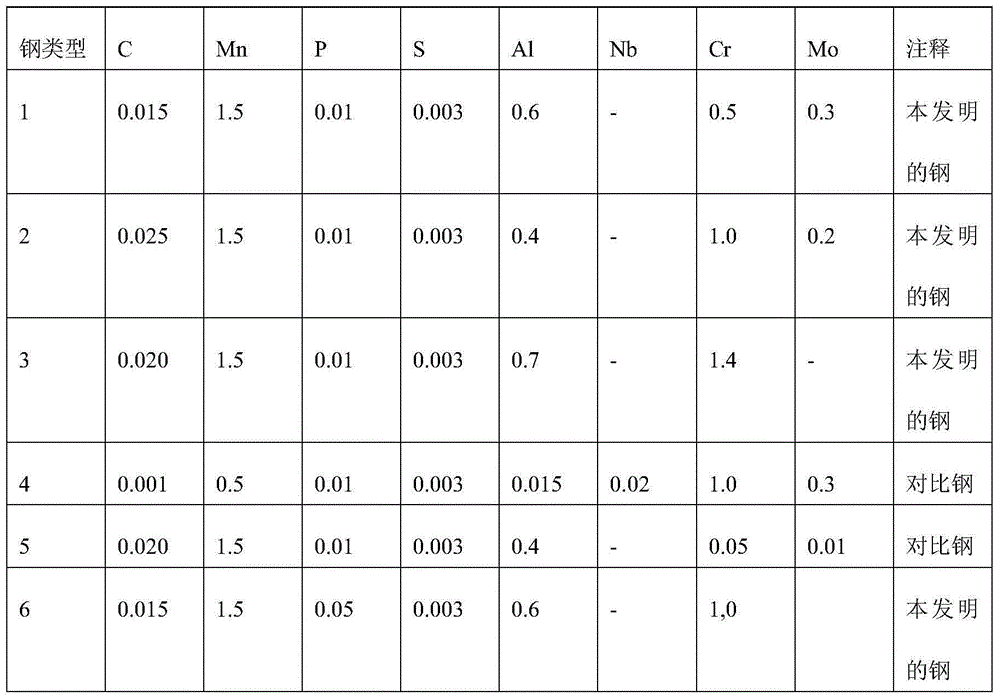

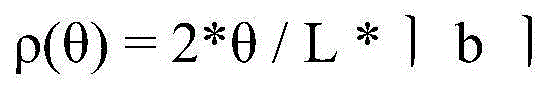

[0085] The steel slabs containing the components shown in Table 1 below and remaining iron and impurities were reheated at a temperature of 1200° C. for 2 hours, and then hot-rolled to obtain hot-rolled steel sheets. Hot rolling was performed at 870° C. (corresponding to a temperature equal to or higher than the Ar3 point) under finish rolling conditions. Each hot-rolled steel sheet was cooled and coiled at 700°C. Then, the coiled steel sheet was pickled and cold rolled at a reduction ratio of 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield ratio | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com