Wind turbine blade having twisted spar web

A technology of wind turbines and spars, which is applied in the direction of the wind engine, wind engine, and blade support elements in the same direction as the wind, and can solve the problem of adding weight to the blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

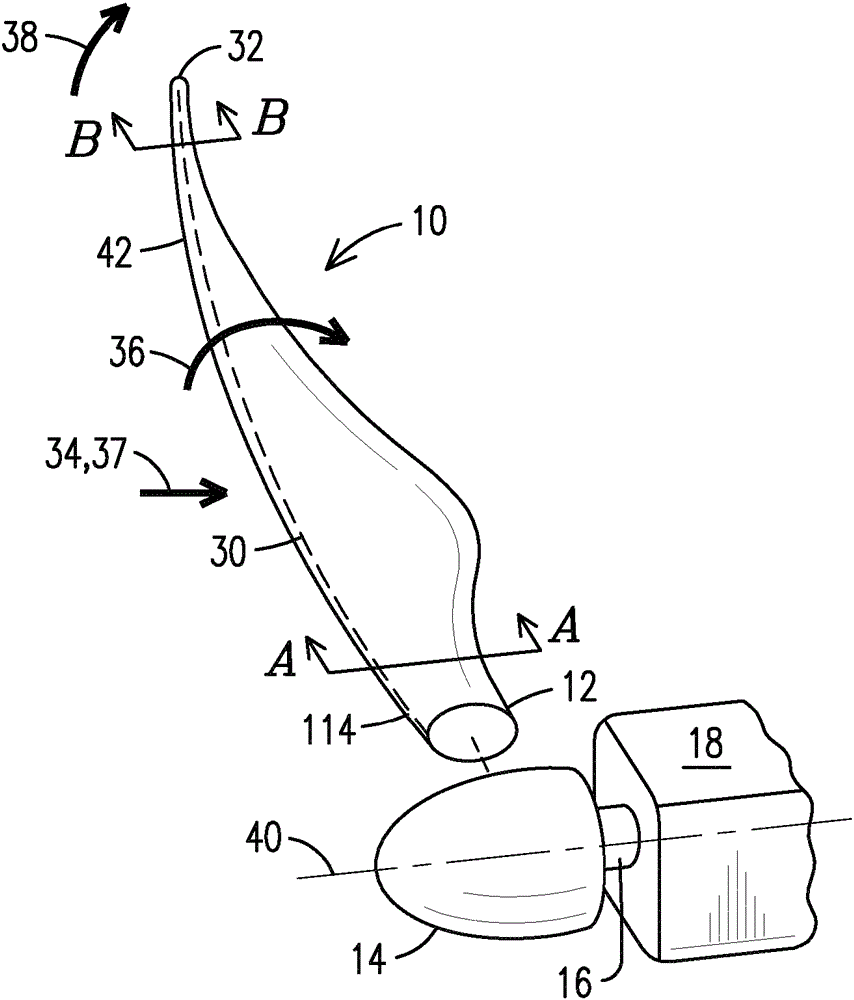

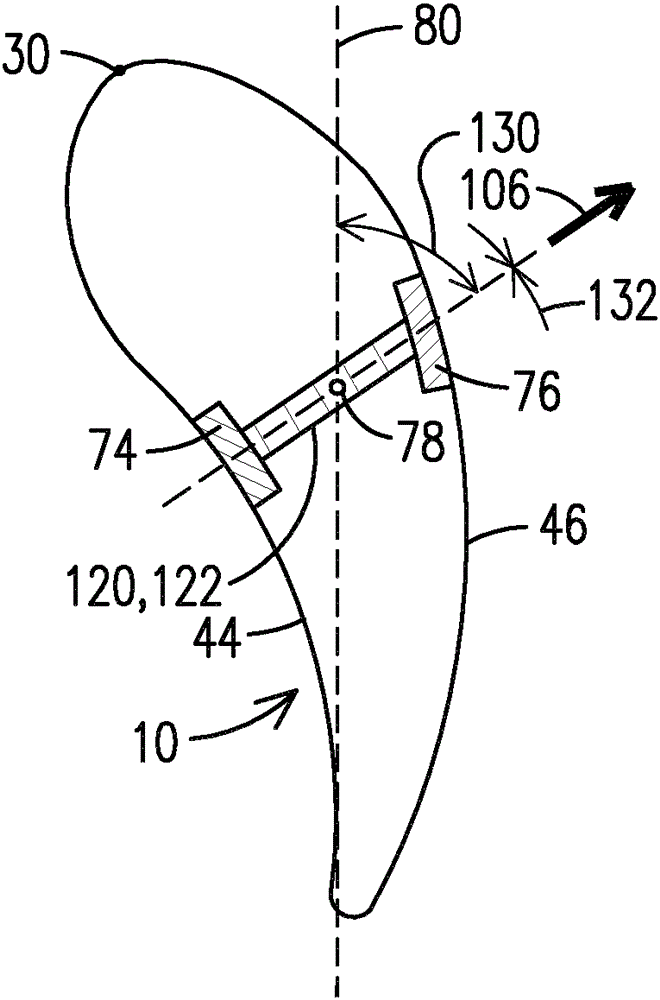

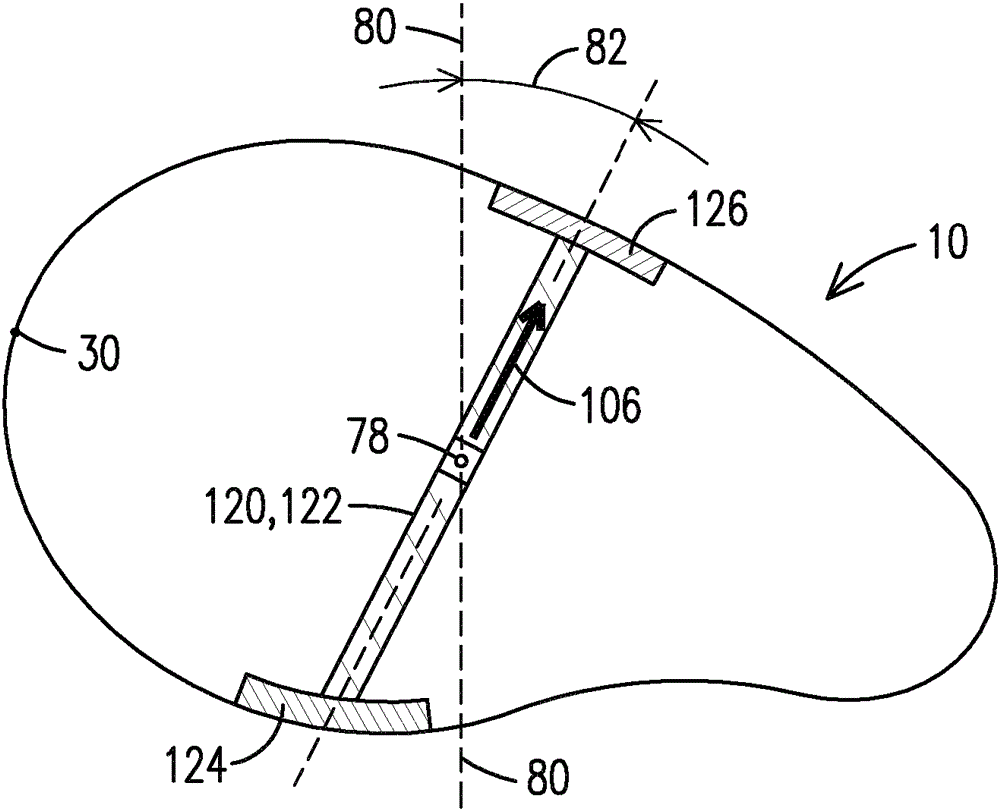

[0020] The inventors of the present invention have realized that blade design has evolved from designing blades with sufficient strength to designing blades with sufficient stiffness to prevent the blade from colliding with the tower support. The inventors of the present invention have also realized that the local force changes from the base of the blade to the tip of the blade. Specifically, at the base of the blade, rotational forces (in the plane of rotation) "build up" from tip to blade to base, while tower deflection forces (toward the tower) are negligible. The skin of the blade is very strong at the blade and is able to withstand its own deflection forces, but may require the assistance of a structural spar to handle rotational forces. Conversely, at the tip of the blade, the rotational force is negligible, while the deflection force has "built up" from the base to the tip, resulting in greater tower deflection. Because the blade is thin and oriented nearly parallel to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com