Fuel cell system

A fuel cell system and fuel cell technology, used in fuel cells, fuel cell additives, fuel cell grouping, etc., can solve problems such as low effective power generation balance, and achieve the effects of high service life and reduced conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

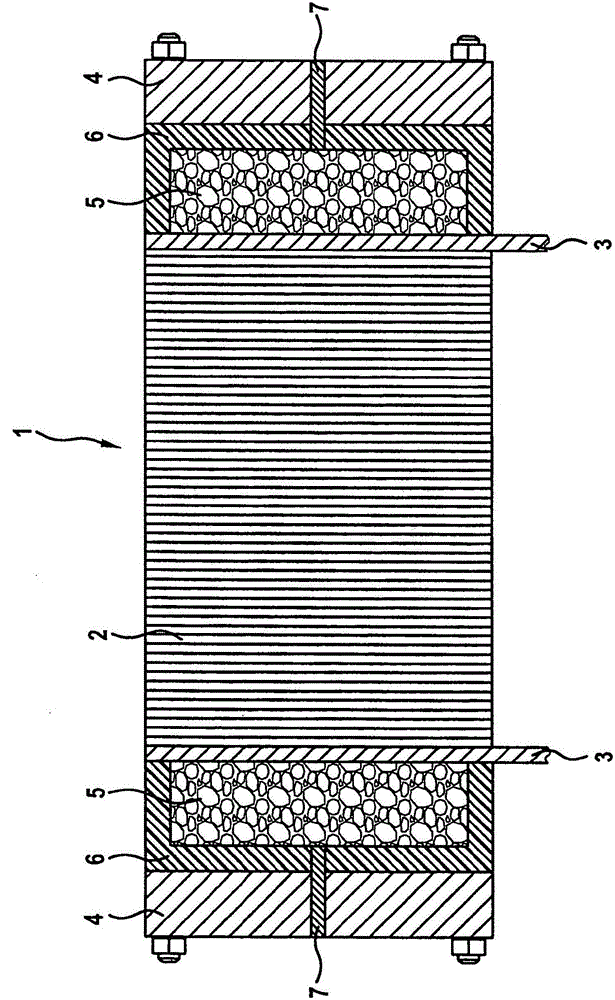

[0022] according to figure 1 , the fuel cell system of the present invention includes a plurality of individual fuel cells 2 combined into a fuel cell stack 1 or stack 1 (and stacked up and down here), wherein the stack of individual fuel cells 2 is at each end The upper part is delimited by a collecting electrode 3, on the side of the collecting electrode facing away from the individual fuel cells, an end plate 4 is arranged. An insulating plate 6 is now also arranged between the respective collector 3 and the respective end plate 4 .

[0023] In addition, a heat accumulator 5 , which is now arranged in a recess in the insulating plate 6 , rests on the side facing away from the individual fuel cells 2 on the collecting electrode 3 . The heat accumulator 5 is designed as a latent heat accumulator (with phase change material PCM) or can be formed as a sorption accumulator (for example with zeolites). As an option (but not shown), the heat accumulator 5 can also be arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com