Endoscopic cutting stapler

A stapler and laparoscopic technology, applied in the field of medical devices, can solve the problems of cumbersome operation, loss of surgical field, increase of potential damage, etc., and achieve the effect of improving surgical effect, reducing surgical damage, and reducing diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

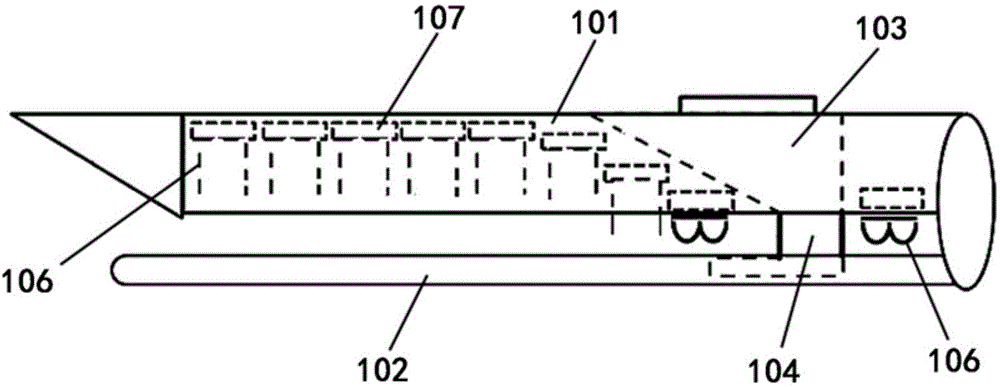

[0062] Such as Figure 5 As shown, the endoscopic cutting stapler of this embodiment includes an anastomosis function part, a connecting rod and an excitation handle, and the anastomosis function part includes a staple cartridge 1, an abutment seat 2, an "I" beam member 3 and a blade ( The blade is not shown in the figure), the staple cartridge 1 is set correspondingly to the nail abutment seat 2, and a part of the "I" beam member 3 is located in the staple cartridge 1, and a part is located in the nail abutment seat 2; the blade and the "work" The word beam member 3 is connected and located between the nail cartridge 1 and the nail abutment seat 2 . Among them, in order to clearly show

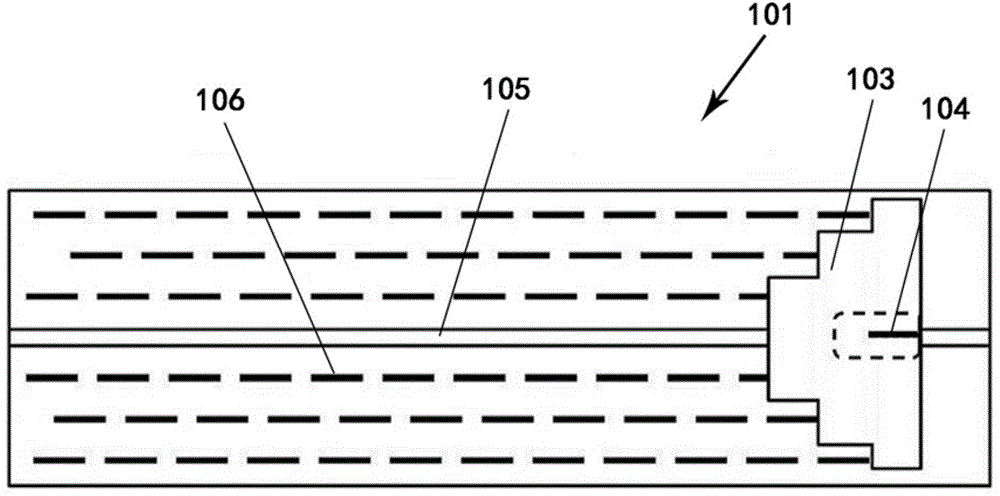

[0063] The side of the staple cartridge 1 opposite to the nail anvil 2 is the first contact surface 5, the side of the nail anvil 2 opposite to the staple cartridge 1 is the second contact surface 6, and the first contact surface 5 is formed by being concave toward the interior of the staple...

Embodiment 2

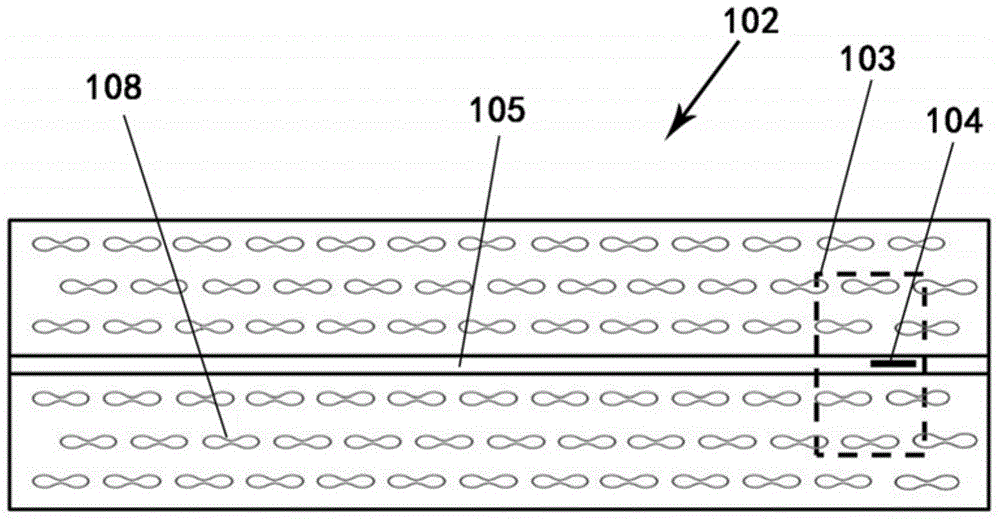

[0069] The difference between this embodiment and the first embodiment lies in that the bending directions of the arc-shaped curved surfaces of the first contact surface 5 and the second contact surface 6 are different. Such as Figure 6 As shown, the first contact surface 5 is a convex arc surface formed outwardly toward the nail anvil 2, and the second contact surface 6 is a concave arc surface formed to be concave toward the interior of the nail anvil 2 and matched with the convex arc surface; The surface 12 is the same convex arc surface as the first contact surface 5; the staples 9 are arranged in a convex arc shape corresponding to the first contact surface 5, so that the "I" beam member 3 can sequentially push the staples 9 for stitching organize. . When the activation handle is activated once, when the "I" beam member 3 moves forward, the pushing surface 12 can accurately push the abutting block 11, thereby pushing out the staples to suture the tissue. The second em...

Embodiment 3

[0071] The first contact surface 5 and the second contact surface 6 may also be polyhedral in addition to being arc-shaped. Such as Figure 7 As shown, the first contact surface 5 is a concave polyhedral shape formed by being concave toward the interior of the staple cartridge 1, the second contact surface 6 is a convex polyhedral shape formed by protruding outward toward the nail cartridge 1 and matching the concave polyhedral shape, and the pushing surface 12 It is the same concave polyhedron shape as the first contact surface 5 .

[0072] continue to combine Figure 7 , in this embodiment, the concave polyhedron shape of the first contact surface 5 includes a first plane 14 , two second planes 15 and two third planes 16 . The first plane 14 is located at the center of the first contact surface 5 ; both sides of the first plane 14 are respectively connected to the second plane 15 and the third plane 16 in sequence. The connection of two adjacent planes forms a knuckle, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com