Driving power foot wheel component, omni-directional moving platform and control method thereof

A technology of omnidirectional movement and casters, which is applied in the field of mobile robots and can solve the problems of low operation efficiency of rollers, easy slippage and noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

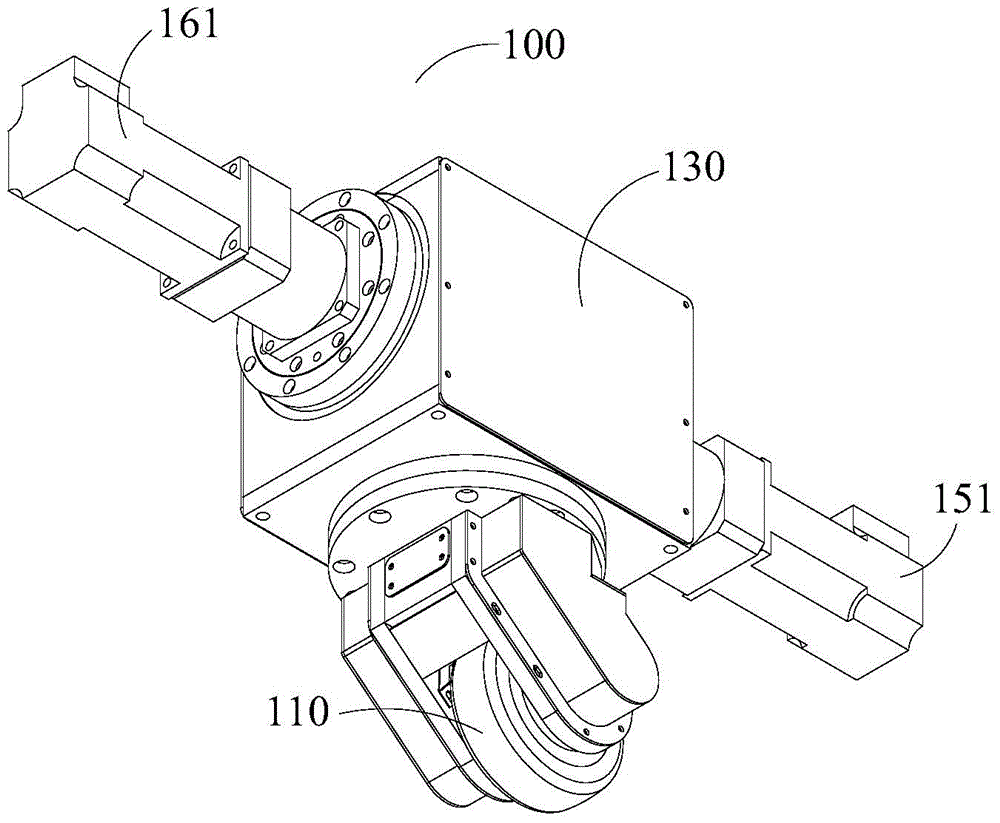

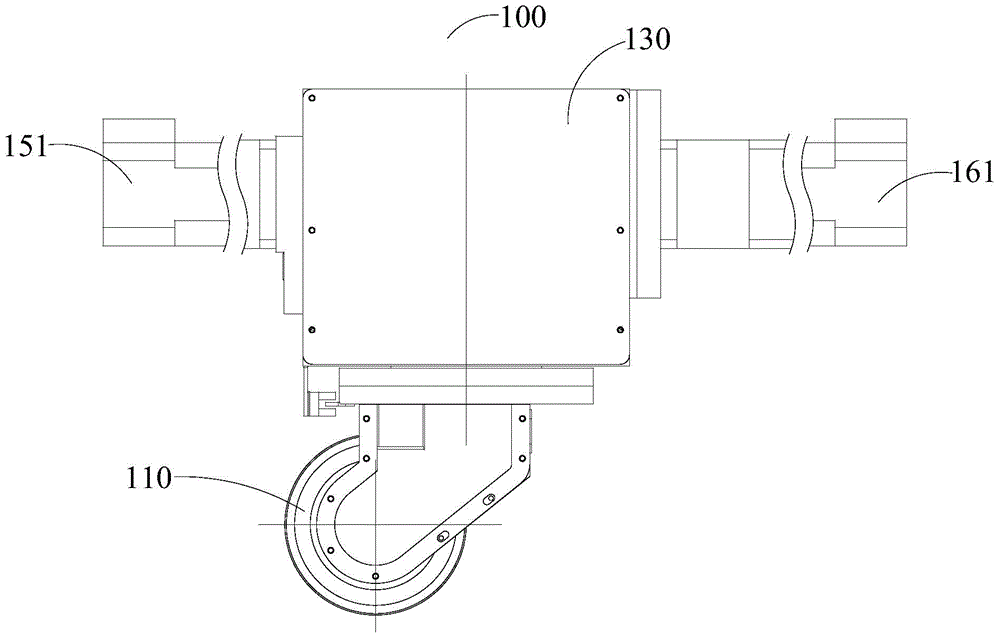

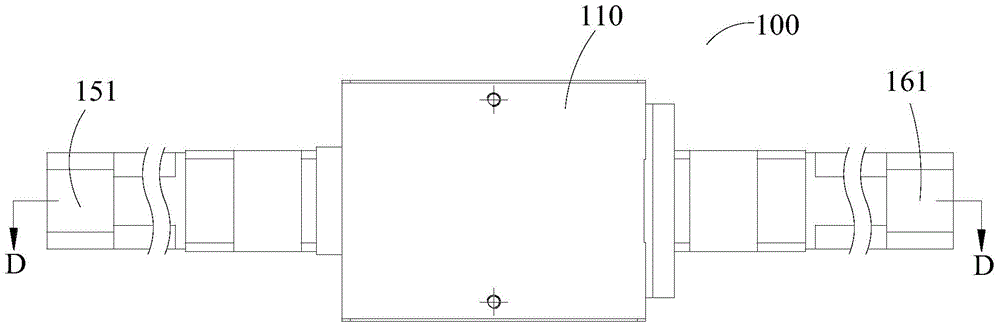

[0091] As a possible implementation, the active power caster assembly 100 also includes a first transmission shaft 170 and a second transmission shaft 180, the first transmission shaft 170 and the second transmission shaft 180 are installed on the wheel frame 130 through the first bearing respectively, and the The first transmission shaft 170 and the second transmission shaft 180 transmit the rolling motion to the roller 110 .

[0092] As a possible implementation, the driving gear set 162 includes a ninth gear 1621, a tenth gear 1622, an eleventh gear 1623, a twelfth gear 1624, a thirteenth gear 1625, a fourteenth gear 1626 and a fifteenth gear 1627. The ninth gear 1621 is sleeved on the hub of the first gear 141, the planetary carrier 145 is installed on the end face of the ninth gear 1621 through a connector, and the driving motor 161 drives the first gear 141 to rotate synchronously with the fifth gear 1521, and the tenth gear 1622 Two second bearings are installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com