Paint heating and stirring device

A technology for heating, stirring and painting materials, which is applied to mixer accessories, dissolving, mixers, etc., can solve the problems of reducing the mixing efficiency of mixers and increasing processing time, and achieve the effect of shortening processing time, improving utilization rate and uniform heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

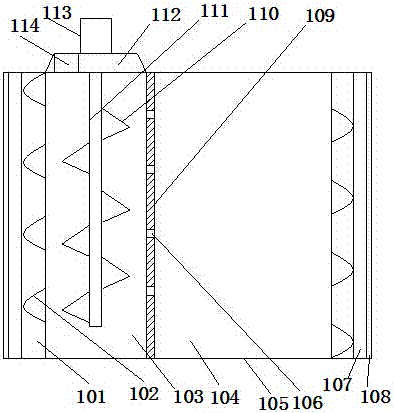

[0012] Example. Paint heating and stirring device, consisting of figure 1 As shown, a container 105 is included. The container 105 can be a barrel container or a square container. The container 105 is provided with a vertical partition 109 to form a stirring area 103 and a mixing area 104 (the partition 109 separates the container A stirring area 103 and a mixing area 104), a plurality of through holes 106 are provided on the partition plate 109, and the through holes 106 may be round holes, square holes, or polygonal holes, and the stirring area 103 is provided with There is an upper cover 112, a motor 113 is arranged on the upper cover 112, the motor 113 is connected with a stirring shaft 111 installed in the stirring area 103, a stirring blade 110 is arranged on the stirring shaft 111, and a fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com