A Bending Method for Asymmetric Profiles with Open Sections

A bending forming, asymmetric technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of profile space deflection, distortion in cross-section, and inability to effectively control, to prevent space deflection, The effect of preventing cross-sectional distortion and strong support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

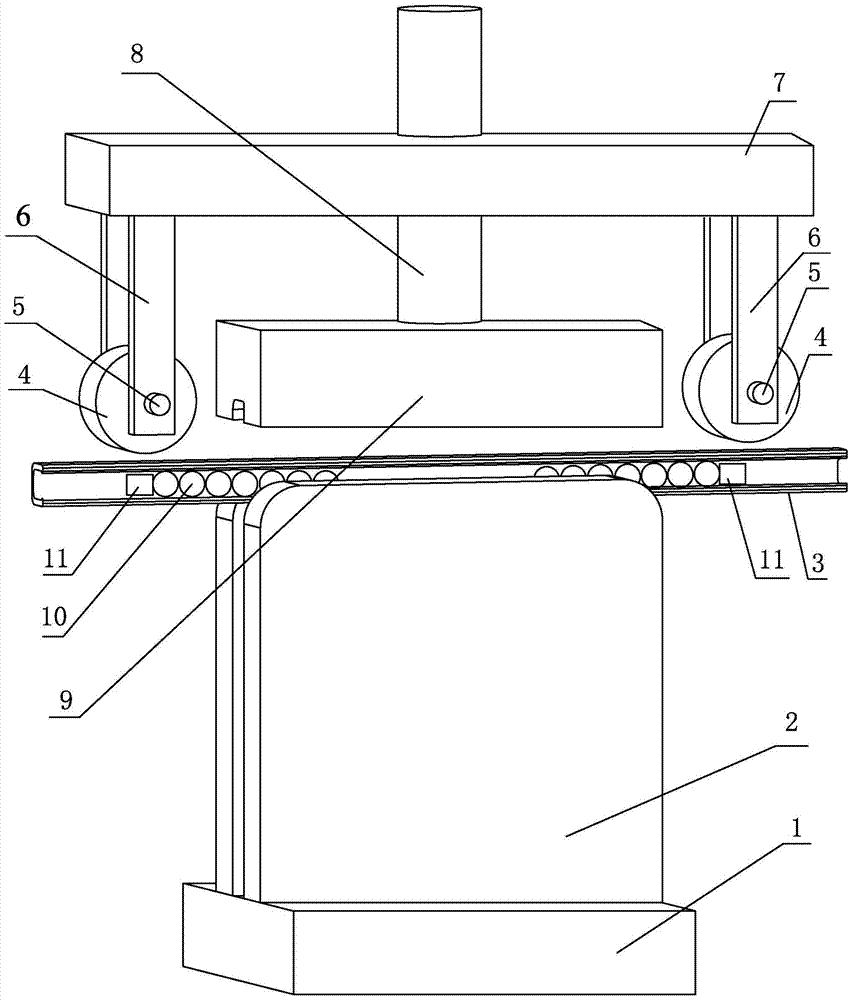

[0018] Specific implementation mode one: combine Figure 1-Figure 6 To illustrate, the bending forming method of an asymmetric profile with an open cross-section in this embodiment is realized according to the following steps:

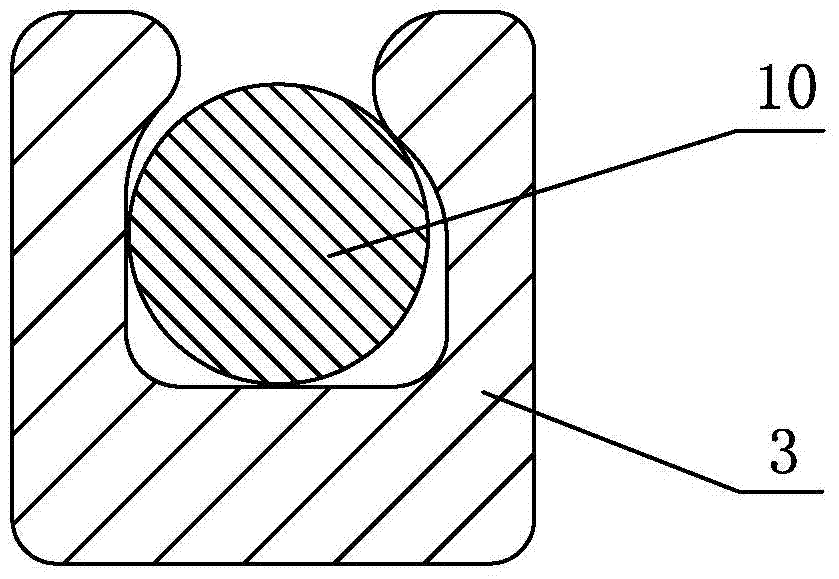

[0019] Step 1: Cutting the asymmetric profile 3 with an open cross-section, and filling the opening between the positions where the asymmetric profile 3 with an open cross-section is to be bent, with several rigid units 10 as the opening of the asymmetric profile 3 with an open cross-section The internal support body, the rigid unit body 10 is limited by the stopper 11 at the position to be bent, the filled open-section asymmetric profile 3 is placed on the bending mold 2 installed on the base 1, positioned and fixed ;

[0020] Step 2. One of the pressure output mechanisms of the double-acting press presses the open cross-section asymmetric profile 3 against the bending mold 2 through the pressing rod 8 and the pressing block 9;

[0021] Step 3. The ...

specific Embodiment approach 2

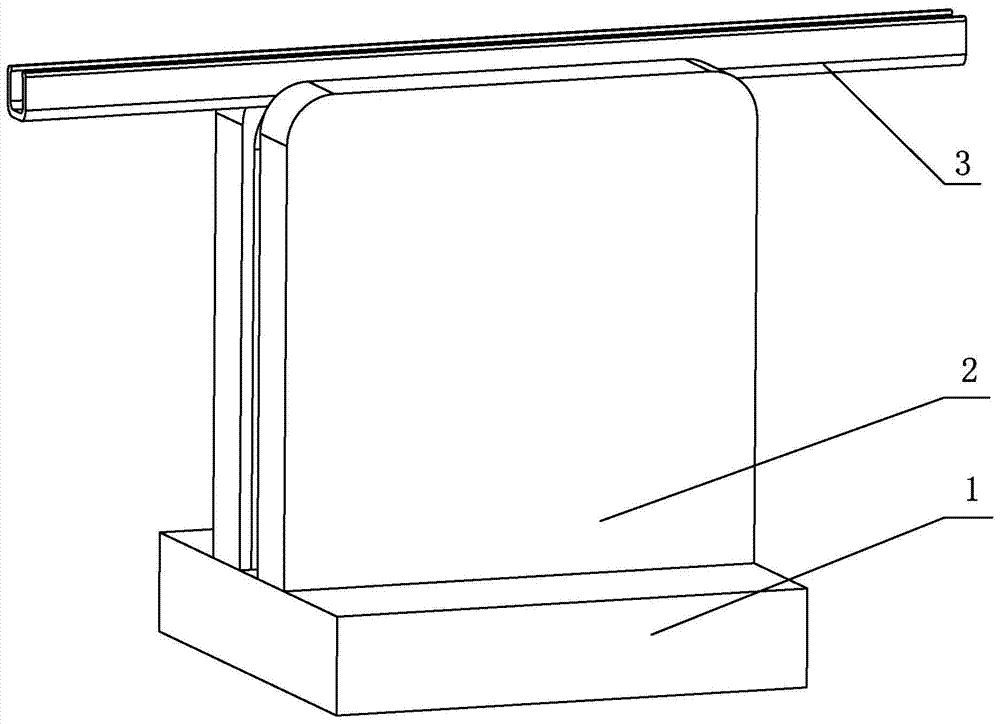

[0026] Specific implementation mode two: combination figure 2 and image 3 Note that in step 1 of the present embodiment, the opening direction of the asymmetric profile 3 with an open cross-section faces the force beam 7 and is set in the moving direction of the bending mold 2, that is, the opening direction of the asymmetric profile 3 with an open cross-section faces the force beam 7 Set in the opposite direction to the bending die movement direction.

[0027] This embodiment is for bending and forming an open-section asymmetric profile 3 whose opening direction is parallel to the radial direction of the bending arc. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination Figure 4 and Figure 5 Note that in step 1 of this embodiment, the opening direction of the asymmetric profile 3 with open cross-section faces the horizontal direction, that is, the opening direction of the asymmetric profile 3 with open cross-section points to the side of the curved arc. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com