Multi-direction spraying industrial robot having color function

An industrial robot, multi-directional technology, applied in manipulators, injection devices, manufacturing tools, etc., can solve the problems of single nozzle setting and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

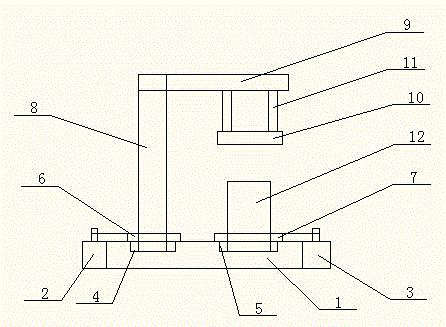

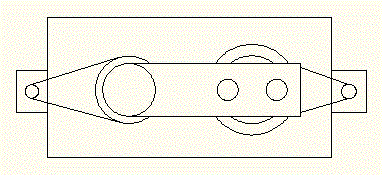

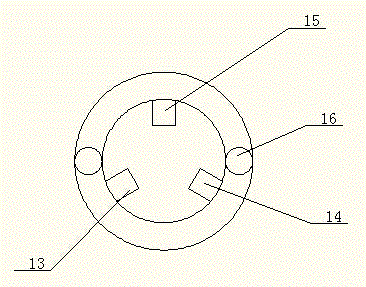

[0018] Below in conjunction with accompanying drawing, the present invention will be further described.

[0019] see Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it includes base 1, No. 1 motor 2, No. 2 motor 3, No. 1 bearing 4, No. 2 bearing 5, No. 1 gear 6, No. 2 gear 7, electric Telescopic rod 8, fixed horizontal plate 9, spraying ring 10, pillar 11, workpiece placement table 12, blue nozzle 13, red nozzle 14, green nozzle 15; No. 2 motor 3, the inside of abutment 1 is respectively provided with No. 1 bearing 4 and No. 2 bearing 5, and No. 1 bearing 4 is provided with electric telescopic rod 8, and the bottom of electric telescopic rod 8 is provided with No. 1 gear 6, and No. 1 gear 6 is connected with the No. 1 motor 2 through a transmission belt; a workpiece placement platform 12 is arranged in the No. 2 bearing 5, and a No. 2 gear 7 is arranged at the bottom of the workpiece placement platform 12, and the No. 2 gear 7 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com