Universal clamp

A clamp and clamping end technology is applied in the field of improvement of general clamps for aircraft assembly tools, which can solve the problems that clamps cannot meet the requirements of use, increase the structural complexity of assembly clamps, etc., and achieve the effect of simplified structure and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below.

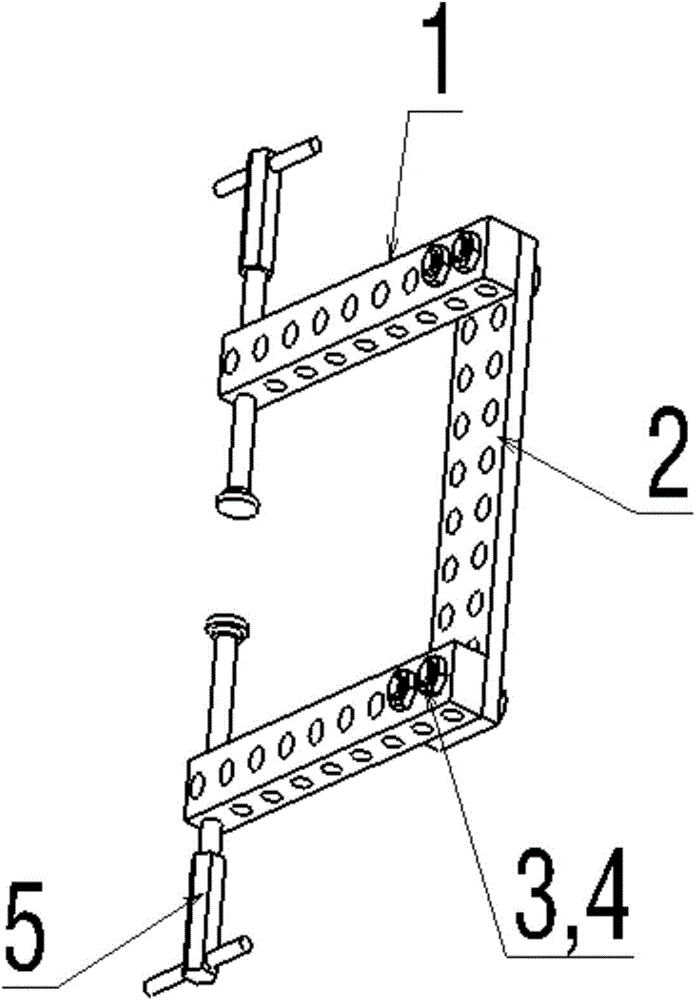

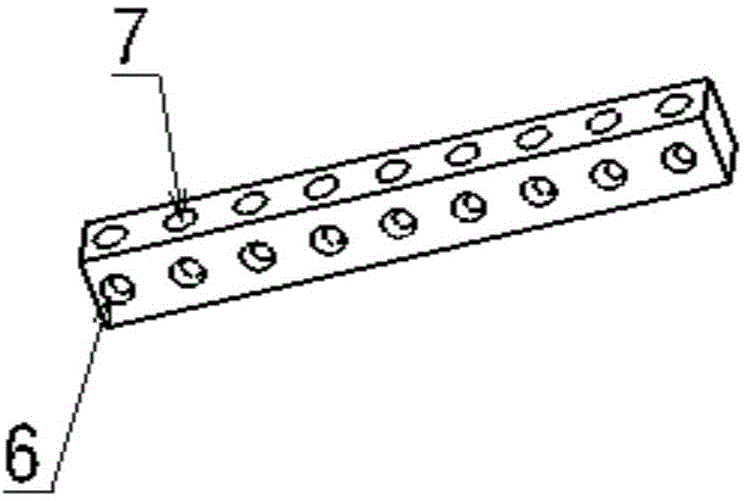

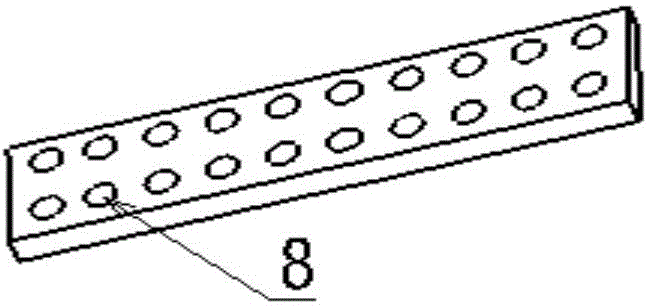

[0014] see Figure 1~4 , the universal clamp of the present invention is composed of the following three basic units: 2 support arms 1, 1 connecting plate 2, 2 compression screw rods 5 are connected and fixed with bolts 3 and nuts 4, and the side of the support arm 1 is equipped with There is a row of connecting holes 6, and a row of threaded holes 7 on the upper and lower surfaces; the connecting plate 2 has two rows of through holes 8; the compression screw 5 is composed of an insertion rod 9 hexagonal column 10, a threaded rod 11, and a pressing piece 12, wherein the insertion rod 9 and the hexagonal prism 10 are matched through hole gaps, the hexagonal prism 10 is welded with the threaded rod 11, and the threaded rod 11 is screwed with the pressure piece 12.

[0015] When the universal clamp of the present invention is used, at first, according to the required size, 2 support arms and 1 connection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com