Aggregating devices for agricultural harvesting machinery

A technology of harvesting machinery and collecting devices, which is applied in the field of mechanical devices, can solve the problems of low center of gravity, increased production costs, and large load capacity of material boxes, and achieve the effects of ensuring stability, improving operating efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

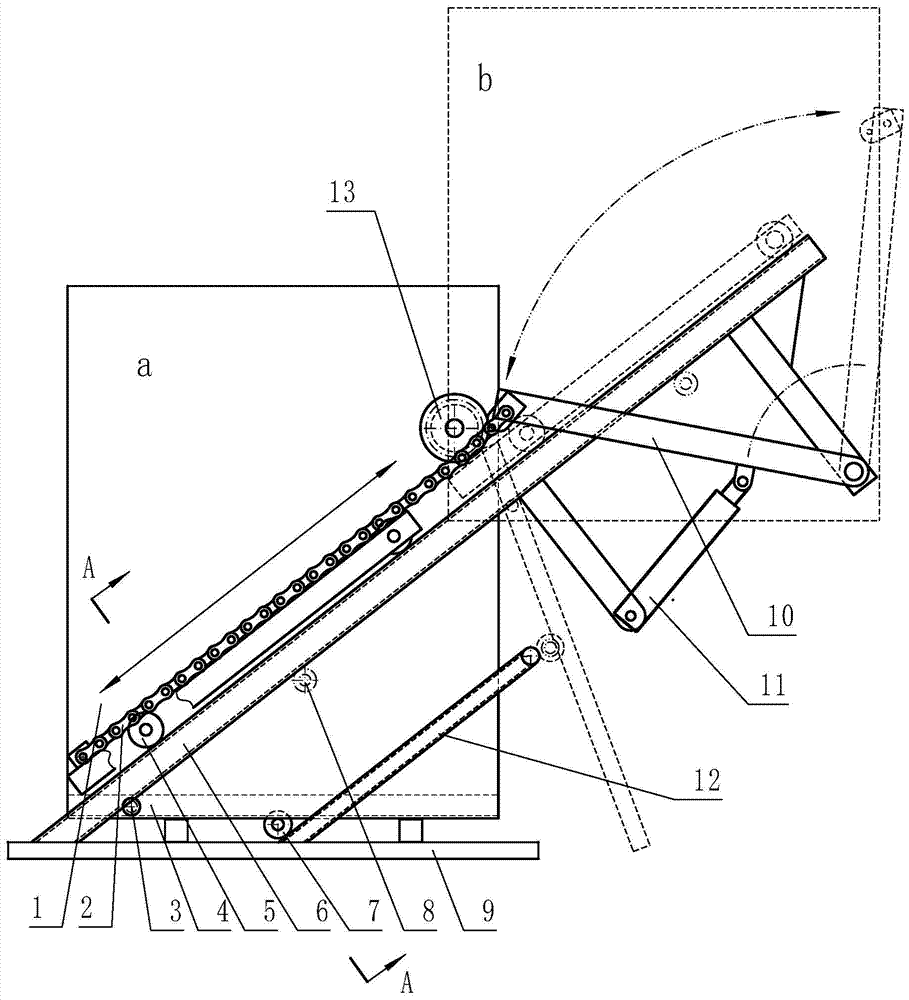

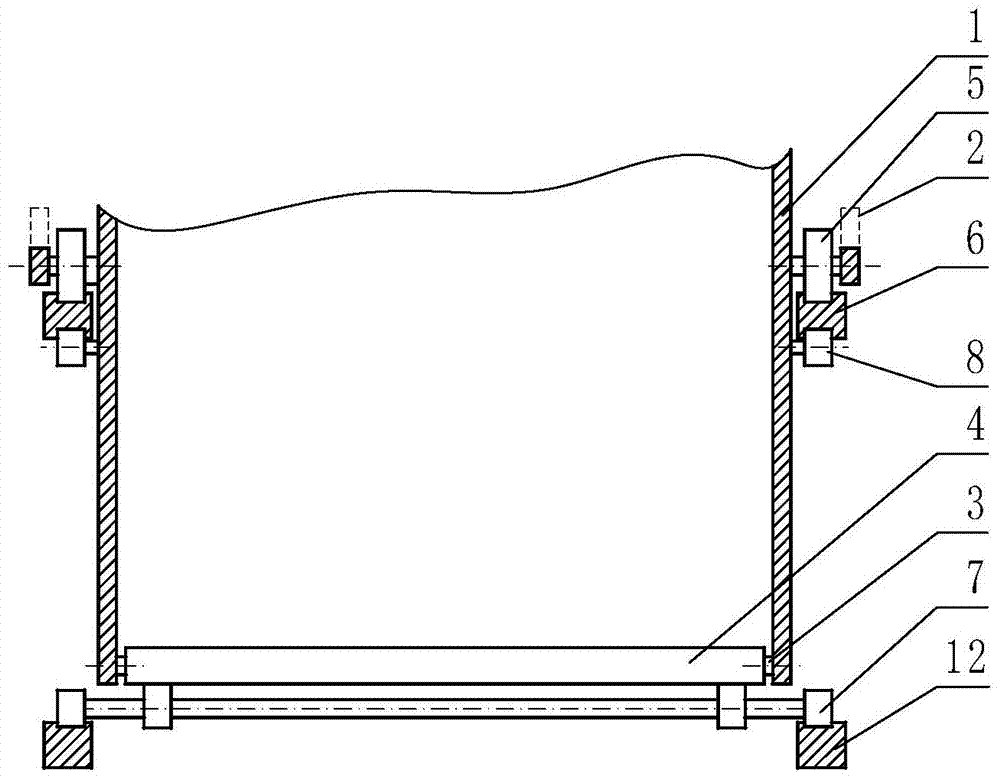

[0018] Embodiment 1: with reference to attached Figure 1-Figure 2 , is a structural schematic diagram of Embodiment 1 of the present invention, including a frame 9 that travels with the main body, and two groups of rail groups that are inclined upward relative to the ground and parallel to each other on different horizontal planes up and down are arranged on the frame 9, that is, the rails A6 and track B12, and the track group at the lower part, that is, track B12, is shorter than the track group at the upper part, that is, track A6, and the upper track group, that is, track A6, is provided with a material box, which contains at least Four side plates 1 and a bottom plate 4 constitute the box body. The bottom plate 4 is a movable plate and is hinged on the side plate 1 of the material box through the pin shaft 3. There are two sets of rollers between the side plates 1 on the left and right sides of the material box and the track A6. A5, each group consists of 3 rollers, the t...

Embodiment 2

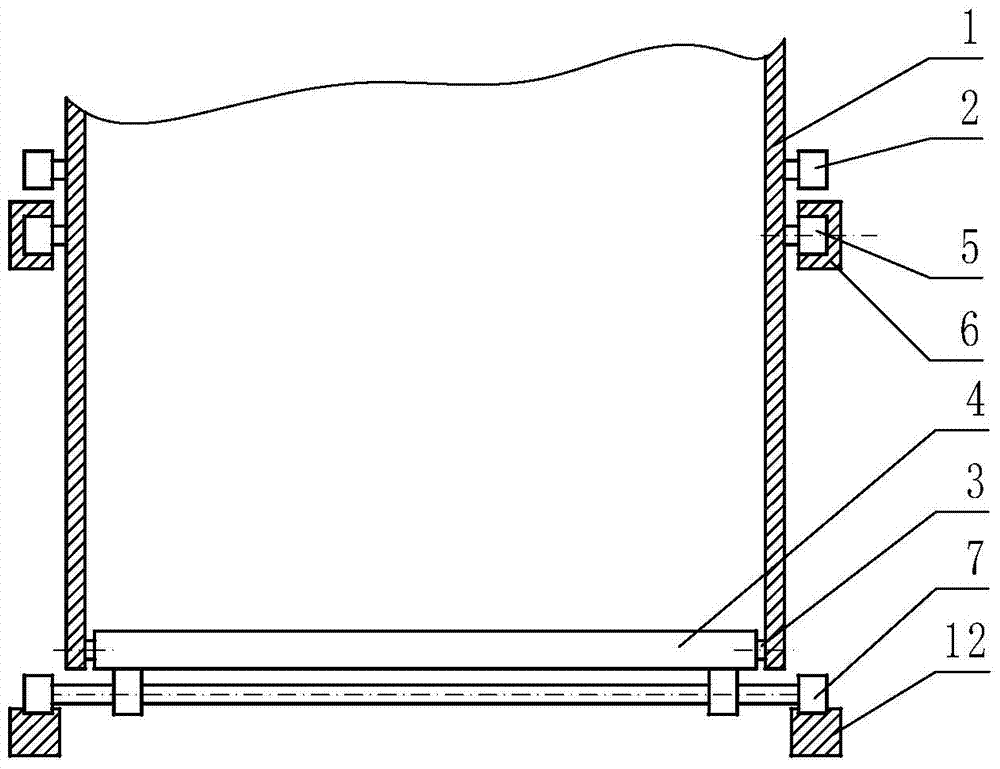

[0019] Embodiment 2: refer to image 3 , is a schematic structural diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is:

[0020] The upper track group, that is, the track of track A6 is a groove, and the roller A5 between the side plate 1 on the left and right sides of the material box and the track A6, each group consists of 2 rollers, and the roller A5 is in the groove of track A6 , it can not only ensure that the box rises or returns to run according to the track, but also prevents the box from derailing during the process of rising or returning, and the structure is simpler.

Embodiment 3

[0021] Embodiment 3: refer to Figure 4 , is a structural schematic diagram of Embodiment 3 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the driving mechanism 11 is a hoist, the driving end of the hoist is connected to the traction rope 2, and the positioning of the traction rope 2 Mechanism 13 is a sheave, and the corresponding traction rope 2 is a steel wire rope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com