Gasifier device and method for gasifying pulverized coal by simultaneously feeding gasifying agents from top burner and furnace body layer by layer and strongly rotating gasifying agents

A technology of gasification agent and gasification furnace, which is applied in the field of coal gasification, and can solve the problems of uneven slag hanging on the wall of the gasification furnace, burning and corrosion of the inner wall of the gasification furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

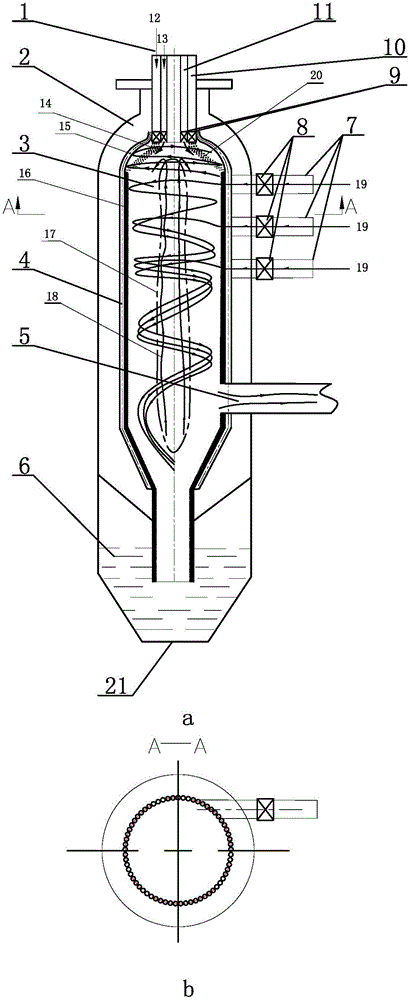

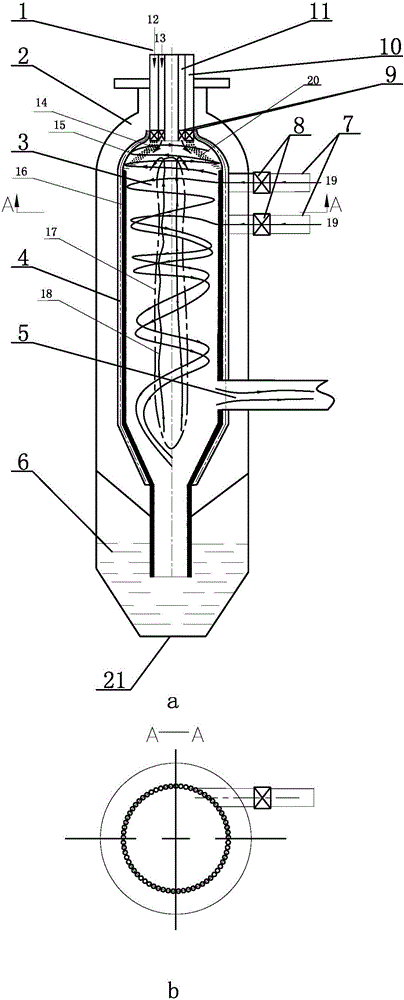

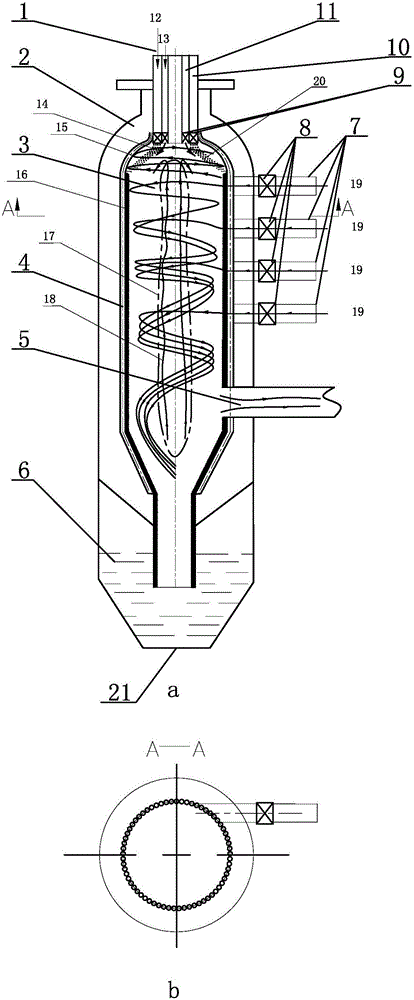

[0025] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a kind of gasification agent described in this embodiment is fed into the strong rotating pulverized coal gasifier simultaneously from the top burner and the furnace body layered Furnace 3, water wall 4, synthesis gas channel 5, slag pool 6, multiple gasification agent nozzles 7, multiple gas flow regulating valves 8, swirl blades 9, pulverized coal channel 10 and gasification agent channel 11, gasifier The body 2 is composed of a hemisphere and a cylinder. The water-cooled wall 4 is installed in the gasification furnace body 2. The water-cooled wall 4 is composed of a plurality of vertical circular tubes arranged side by side. The gasification furnace 3 is a rotary wall surrounded by the water-cooled wall 4. body, the slag pool 6 is located at the bottom of the gasification furnace body 2, the syngas channel 5 is inserted in the lower part of the gasification furnace body 2, and a...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination figure 1 To illustrate this embodiment, a gasification agent described in this embodiment is fed into the strong rotary pulverized coal gasification furnace device simultaneously from the top burner and the furnace layer. The multiple gasification agent nozzles 7 refer to three gasification agents Spout 7. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Specific implementation mode three: combination figure 2 To illustrate this embodiment, a gasification agent described in this embodiment is simultaneously fed into a plurality of gasification agent nozzles 7 of a strong rotary pulverized coal gasifier device from the top burner and the furnace body in layers, referring to two gasification agents Spout 7. Other components and connections are the same as those in the first embodiment.

[0028] Specific implementation mode four: combination image 3 To illustrate this embodiment, a gasification agent described in this embodiment is fed into the strong rotary pulverized coal gasification furnace device at the same time from the top burner and the furnace layer. The multiple gasification agent nozzles 7 refer to four gasification agents Spout 7.

[0029] Specific implementation mode five: combination Figure 1 to Figure 3 To illustrate this embodiment, a gasification agent described in this embodiment is simultaneously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com