A washing machine with internal circulation system

A recycling system and washing machine technology, applied in other washing machines, household appliances, washing devices, etc., can solve the problems of complicated production process, reduced component versatility, increased washing machine cost, etc. The effect of large washing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

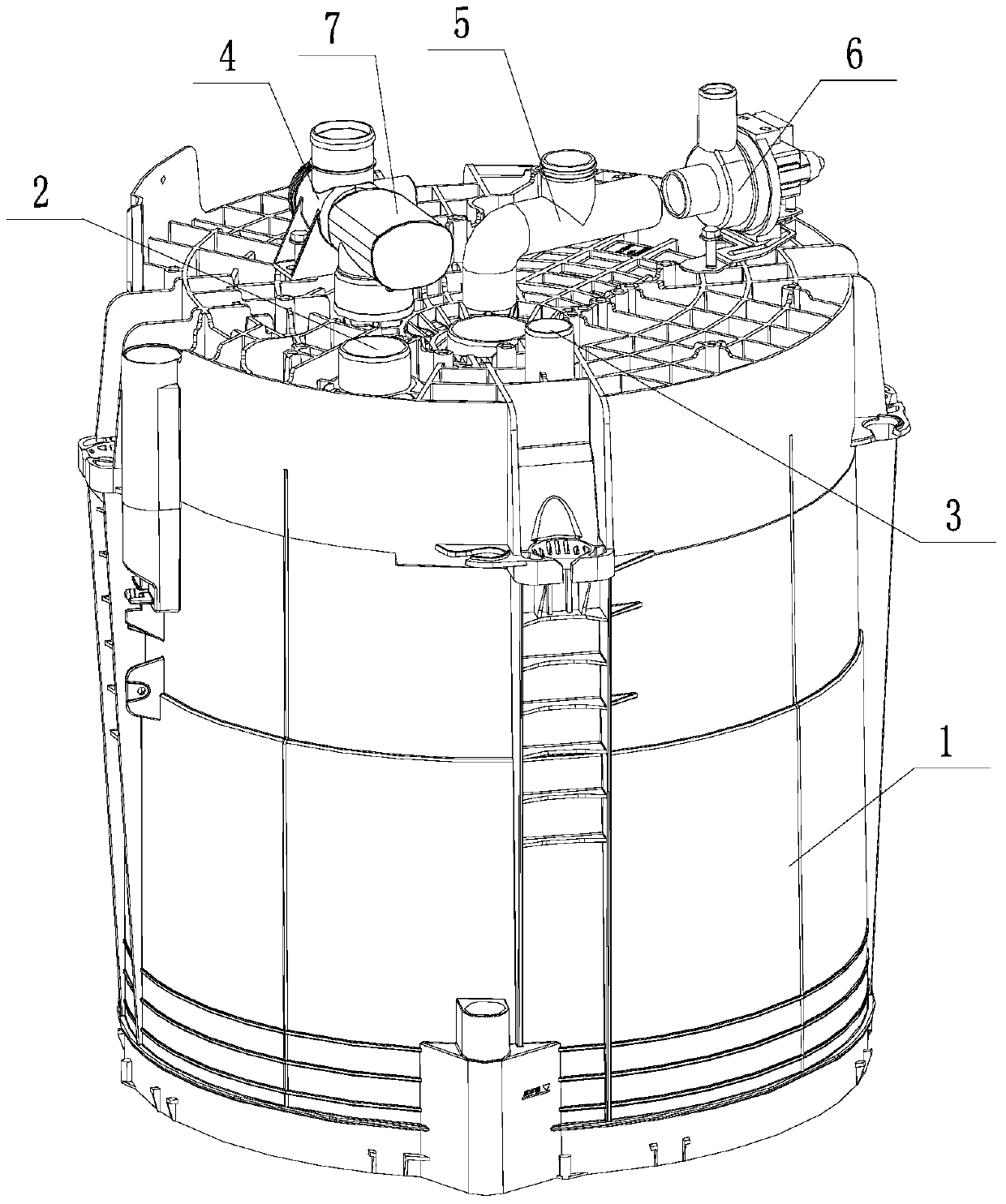

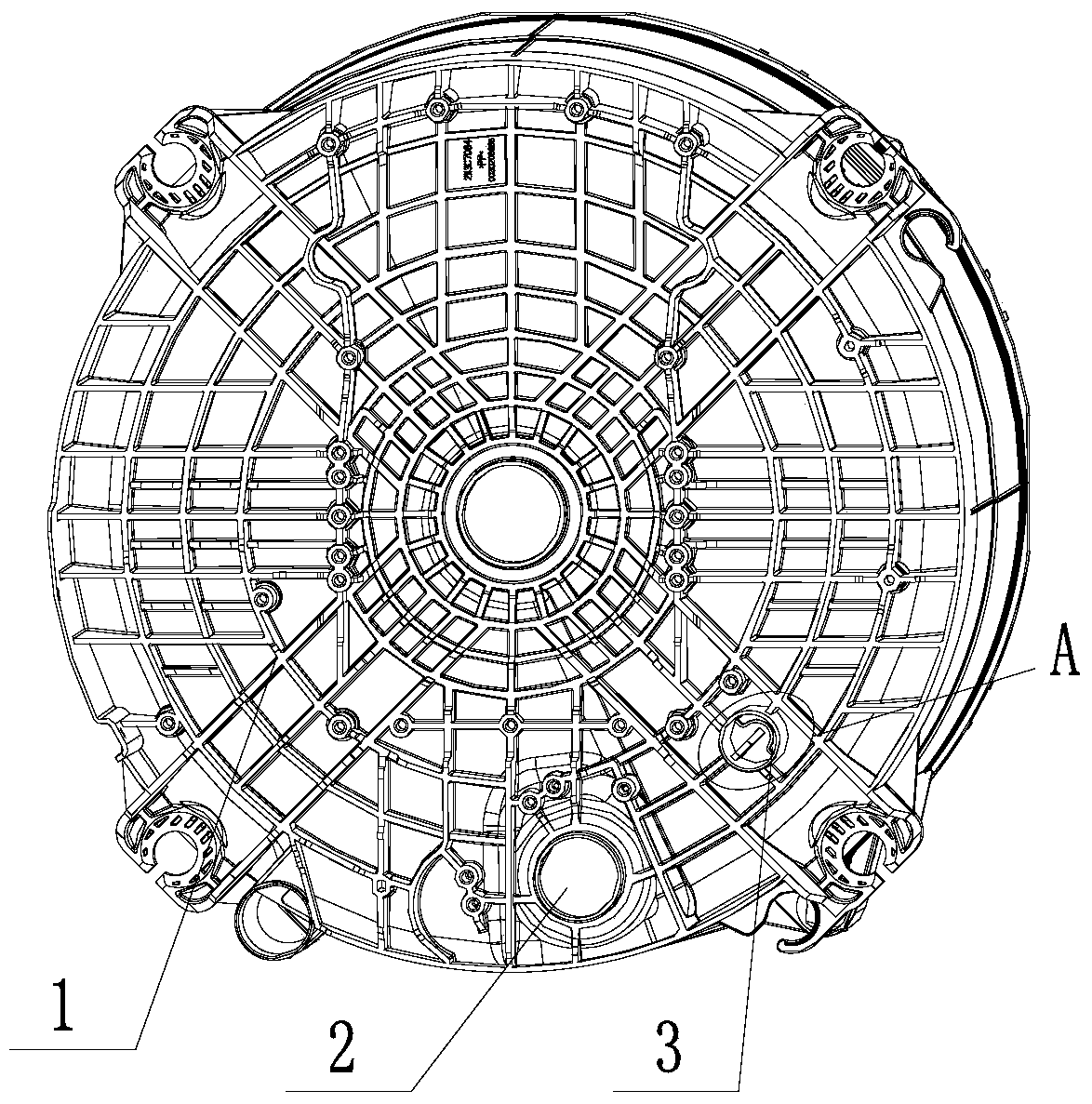

[0036] Such as Figure 7 As shown, the inlet of the drain valve 4 in this embodiment is connected to the first drain port 2, the outlet of the drain valve 4 is connected to the drain pipe of the washing machine, and the inlet of the circulation pump 6 is directly inserted into the second drain port 3. The circulating pump is connected to the bottom of the outer barrel through bolts or screws, and a sealing ring is provided at the joint, and the water inlet of the circulating pump is perpendicular to the bottom of the outer barrel. The outlet of the circulation pump 6 is connected with the internal circulation pipeline. The water inlet of the circulating pump 6 is directly connected to the second drain port 3, and the washing water flows through the second drain port 3, the circulating pump 6, and the circulation pipeline and then sprays into the inner tub through the spray structure, so as to realize the internal circulation of the water flow, so that in the washing When the ...

Embodiment 2

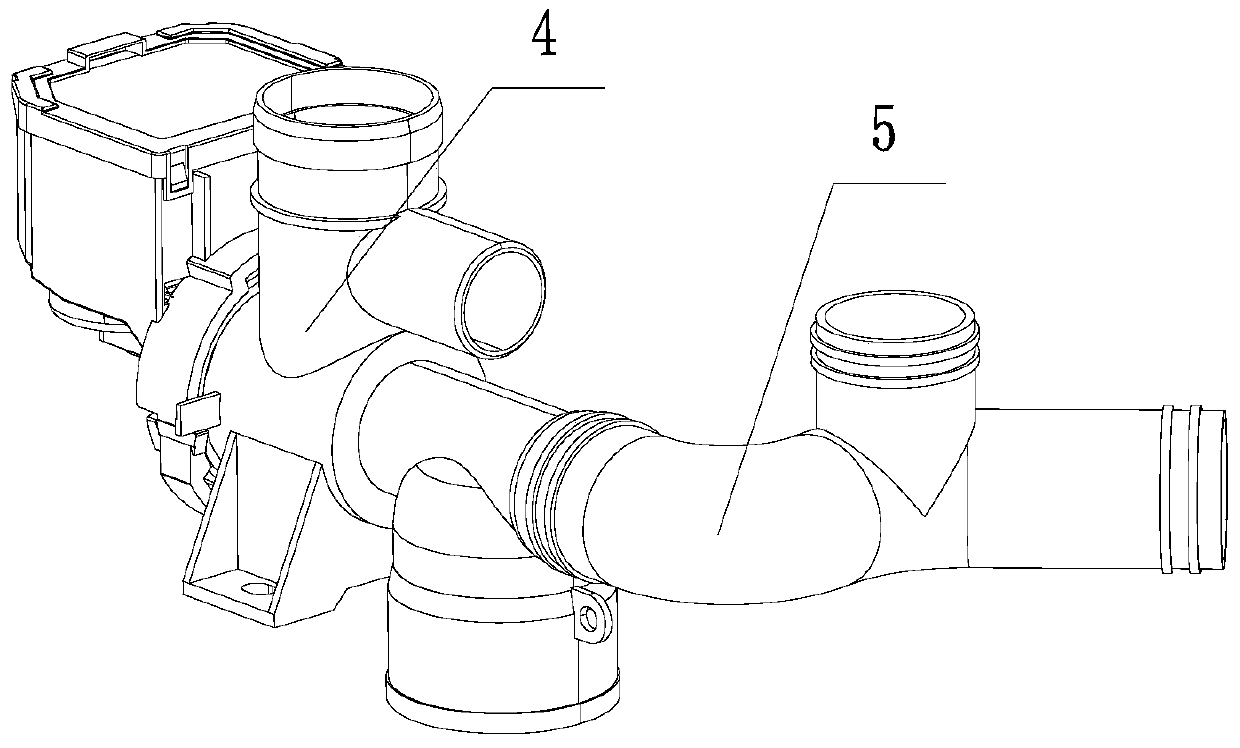

[0038] Such as image 3 , Figure 4 , Figure 5 , Figure 6 As shown in the embodiment, a drain valve 4 is provided at the first drain port 2, which is connected to the drain pipe through the drain valve 4, and a connecting pipe 5 is provided at the second drain port 3, and the inlet of the connecting pipe 5 is connected to the second drain port. The drain port 3 is connected, the water outlet of the connecting pipe 5 is connected with the water inlet of the circulation pump 6, and the water outlet of the circulation pump 6 is connected with the internal circulation pipeline. In this way, the washing water passes through the second drain port 3, the connecting pipe 5, the circulation pump 6, and the circulation pipeline and then sprays back into the inner bucket through the spray structure, so as to realize the internal circulation of the water flow, and the beating of the water flow can form more abundant foam. It is conducive to the penetration of foam and washing liquid ...

Embodiment 3

[0041] The washing machine described in this embodiment is a self-cleaning washing machine. A cleaning ball is provided between the inner tub and the outer tub 1 to clean the tub wall between the inner and outer tubs. The drain valve is provided with a filter structure to filter the cleaning ball to avoid cleaning. The balls are discharged with the drain pipe, and a chamber is set on the drain valve as the cleaning ball storage room 7. When dehydration or the washing machine is not in use at ordinary times, the cleaning balls are stored in the cleaning ball storage room 7 through the blocking of the filter structure. The filter structure can be Filters or retaining ribs.

[0042] The second drain port 3 can be a circular drain port, and a filter structure is also provided in the connecting pipe 5 to filter the cleaning balls, so as to prevent the cleaning balls from entering the circulating pump and being broken, or damaging the circulating pump.

[0043] The second drain port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com