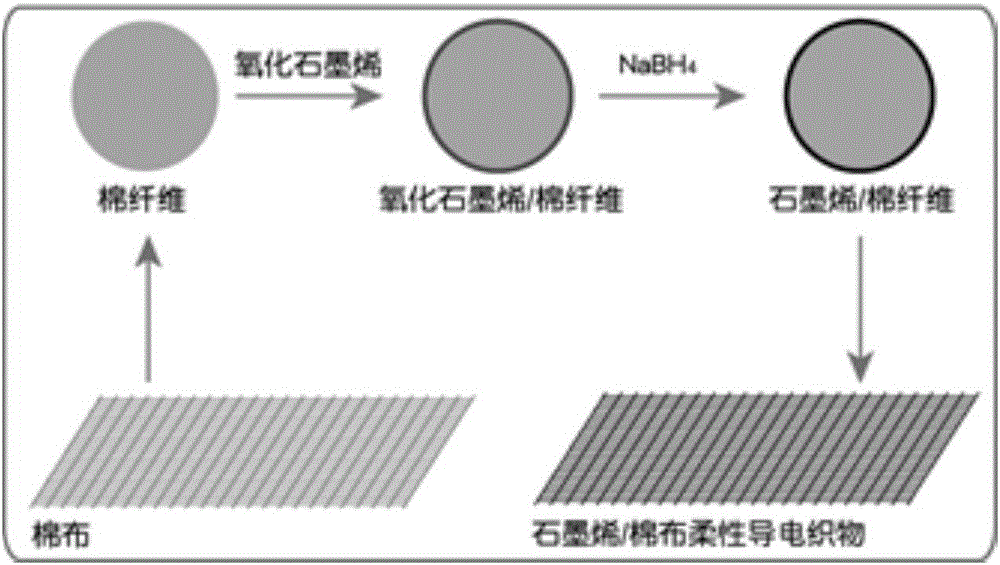

Graphene/cotton cloth flexible conducting fabric and preparing method of graphene/cotton cloth flexible conducting fabric

A flexible conductive and graphene technology, used in plant fibers, textiles and papermaking, fiber processing, etc., can solve problems such as long processes, achieve broad application prospects, reduce waste water discharge, and facilitate operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

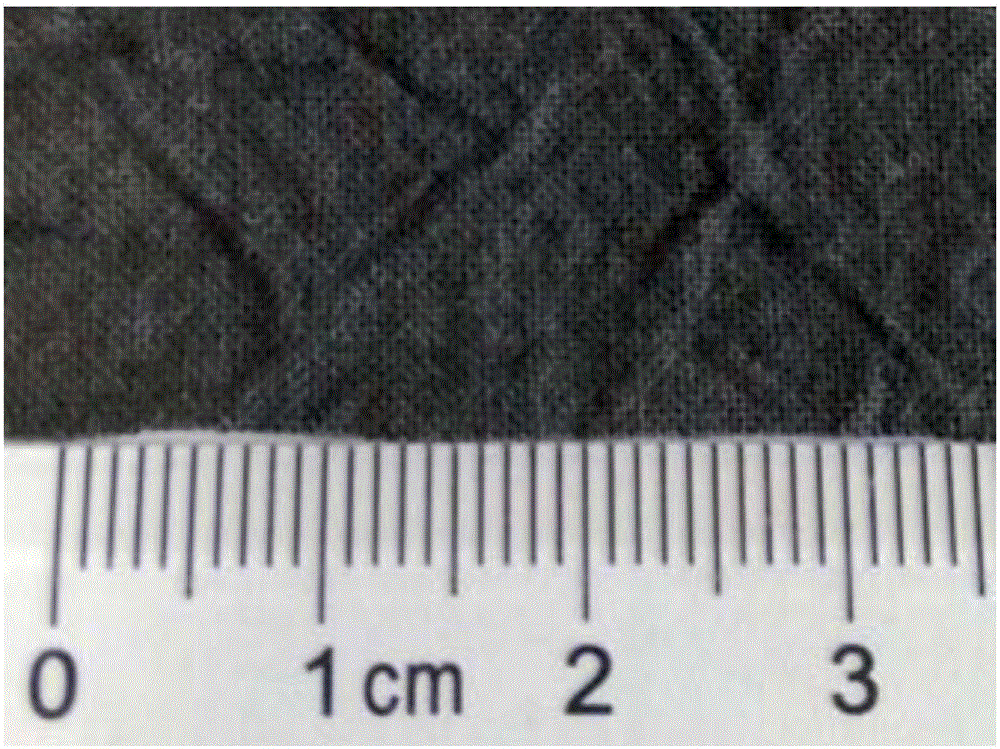

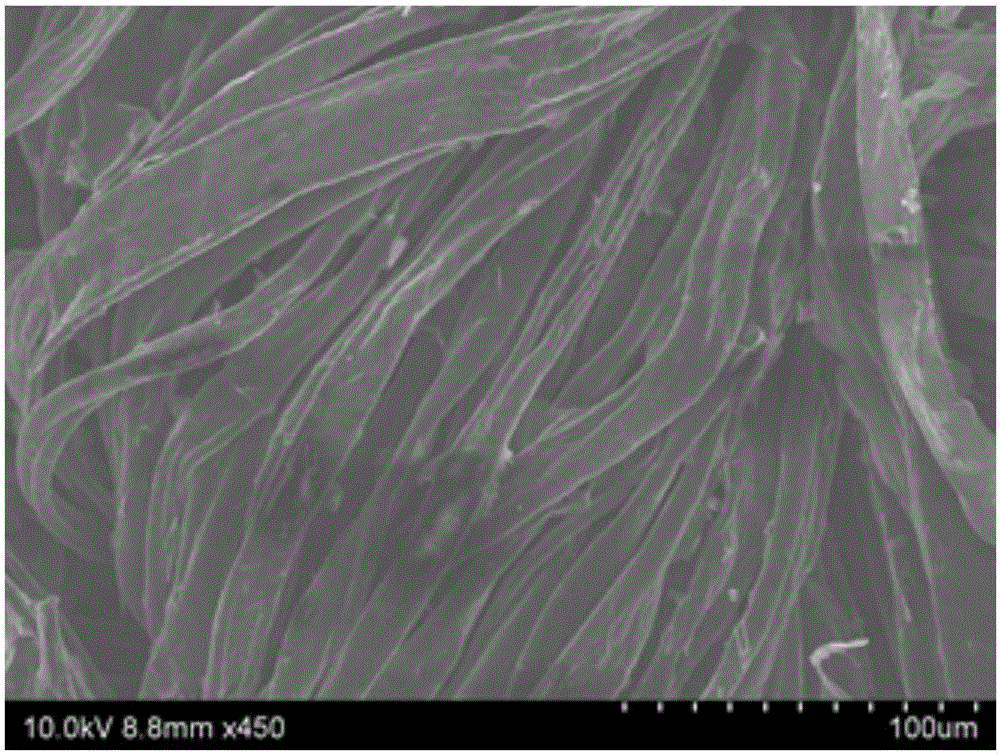

[0033] Prepare a 2mg / mL graphene oxide aqueous solution, soak the cotton fabric in the above solution, stir at room temperature for 30min, then dry the fabric in a vacuum oven at 50°C for 2h, repeat the dipping-drying process 20 times, and then obtain The graphene oxide / cotton composite fabric was impregnated in 0.15mol / L NaBH 4 The solution was stirred for 12 hours, and the stirring temperature was at room temperature. Finally, it was taken out and washed with water, and dried at 105° C. for 1 hour to obtain a graphene / cotton flexible conductive fabric.

Embodiment 2

[0035] Prepare a 2mg / mL graphene oxide aqueous solution, soak the cotton fabric in the above solution, stir at room temperature for 30min, then dry the fabric in a vacuum oven at 50°C for 2h, repeat the dipping-drying process 20 times, and then obtain The graphene oxide / cotton composite fabric was impregnated in 0.3mol / L NaBH 4 The solution was stirred for 12 hours, and the stirring temperature was at room temperature. Finally, it was taken out and washed with water, and dried at 105° C. for 1 hour to obtain a graphene / cotton flexible conductive fabric.

Embodiment 3

[0037] Prepare a 2mg / mL graphene oxide aqueous solution, soak the cotton fabric in the above solution, stir at room temperature for 30min, then dry the fabric in a vacuum oven at 50°C for 2h, repeat the dipping-drying process 20 times, and then obtain The graphene oxide / cotton composite fabric was impregnated in 0.5mol / L NaBH 4 The solution was stirred for 12 hours, and the stirring temperature was at room temperature. Finally, it was taken out and washed with water, and dried at 105° C. for 1 hour to obtain a graphene / cotton flexible conductive fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com