Wall face tile pavement structure

A wall brick and pavement technology, which is applied in building structure, covering/lining, construction, etc., can solve the problems of prolonging the construction period, falling off of decorative bricks, and high difficulty of construction, so as to prolong the service life and safety, and improve the smoothness , Improve the effect of aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

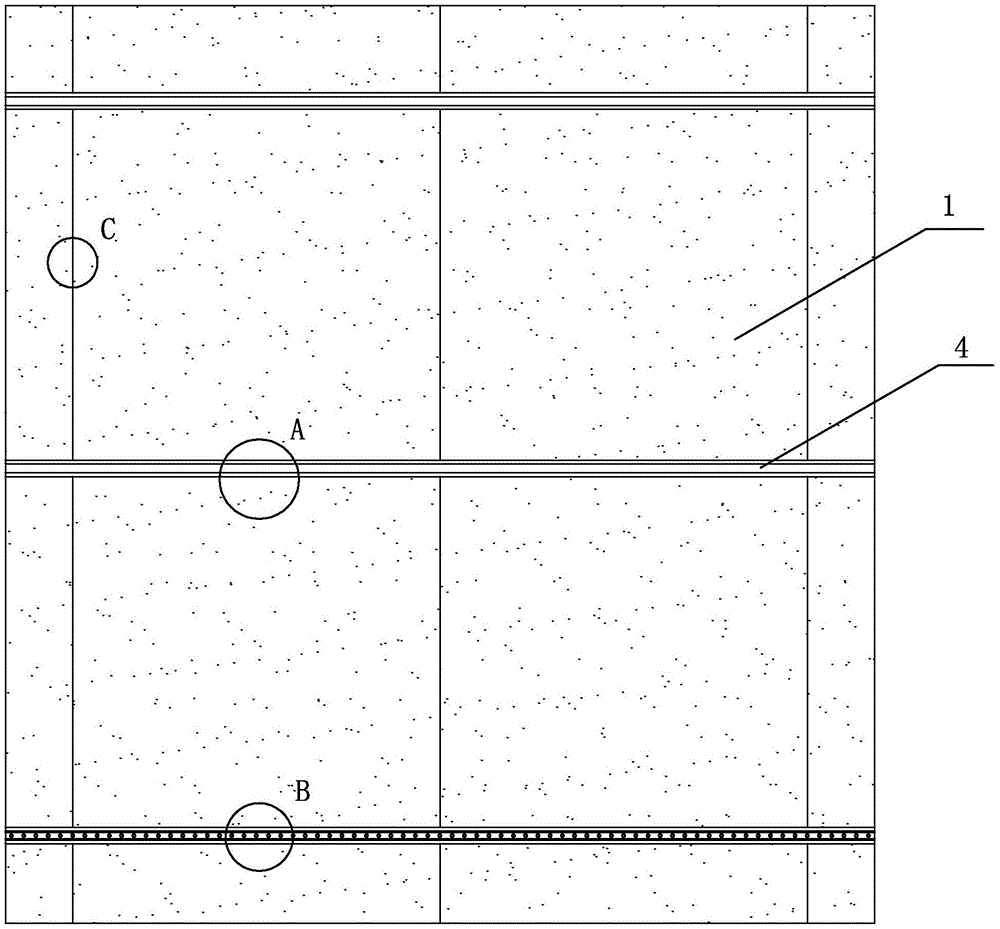

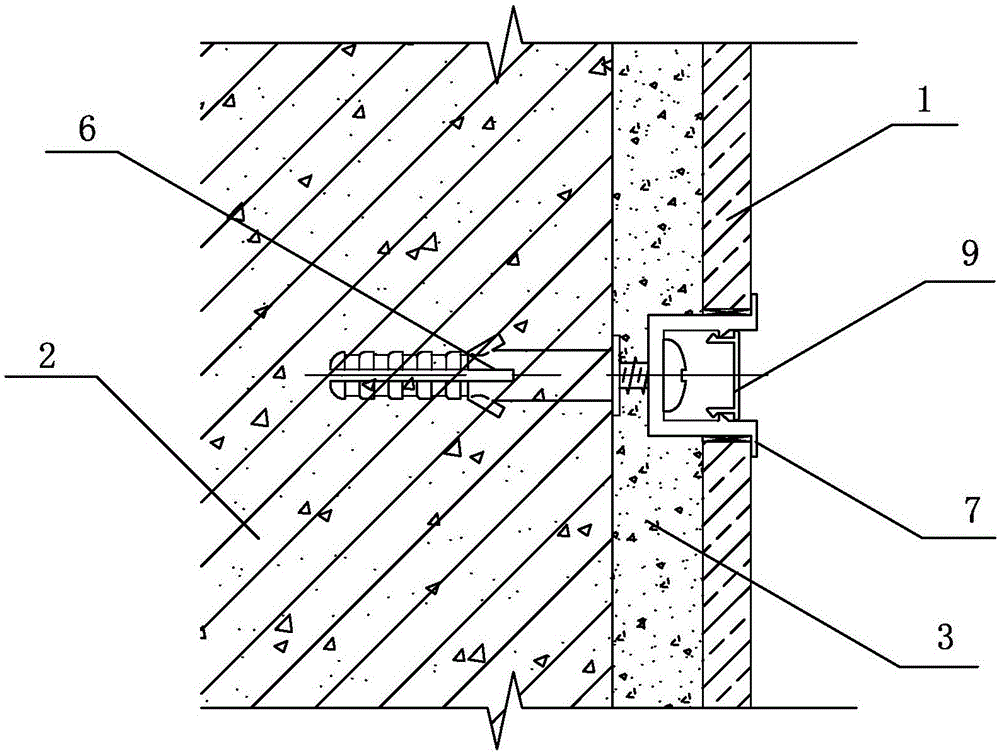

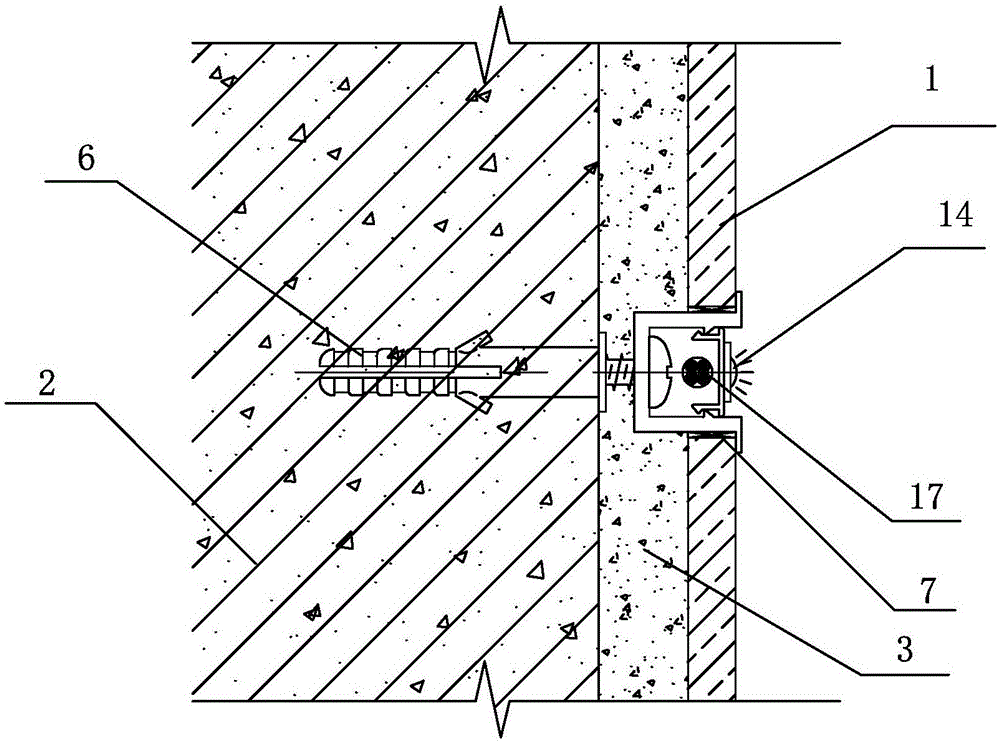

[0027] Embodiment one: see Figure 1~5 As shown, a wall brick pavement structure includes a cement mortar layer 3 between the brick 1 and the wall 2, a plurality of support structures 4, and the support structures 4 are distributed on the upper and lower adjacent In the brick joints between the facing bricks 1, each of the support structures 4 includes a concave base bar 5 and a plurality of fixing bolts 6, and the concave base bar 5 is arranged along the horizontal direction where the facing bricks 1 are laid. And the facing bricks on the corresponding upper and lower sides are respectively provided with flanging 7, and the facing bricks 1 are positioned at the inner side of the flanging 7, and the end faces of the upper and lower bricks are against the sides of the concave base bar 5, and between the two Spacers 8 are provided between them; the fixing bolts 6 are expansion bolts, which are arranged at intervals in the concave base bar 5 at intervals of 200mm-400mm (preferabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com