Dual bore microelectrode pusher

A technology of micro-electrode and pusher, which is applied in wellbore/well components, measurement, earthwork drilling and production, etc. It can solve the problem that the pusher arm of the pusher is opened or retracted at the same time, and the microelectrode plate cannot be continuously attached to the well wall Measurement and other issues, to achieve accurate and efficient measurement values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

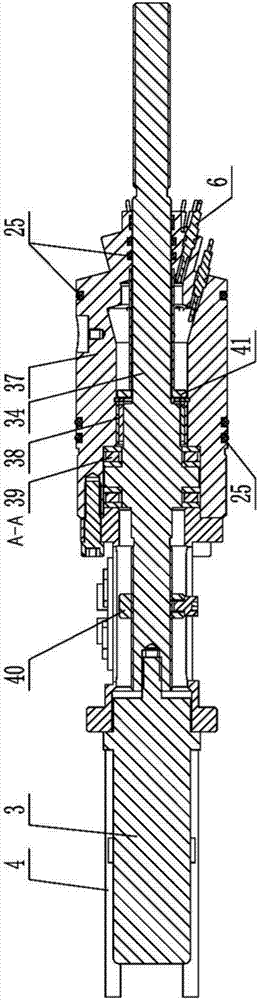

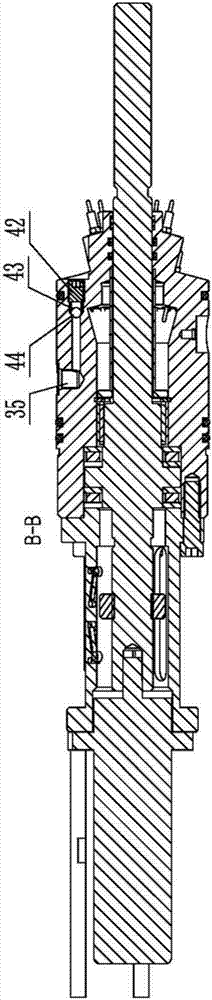

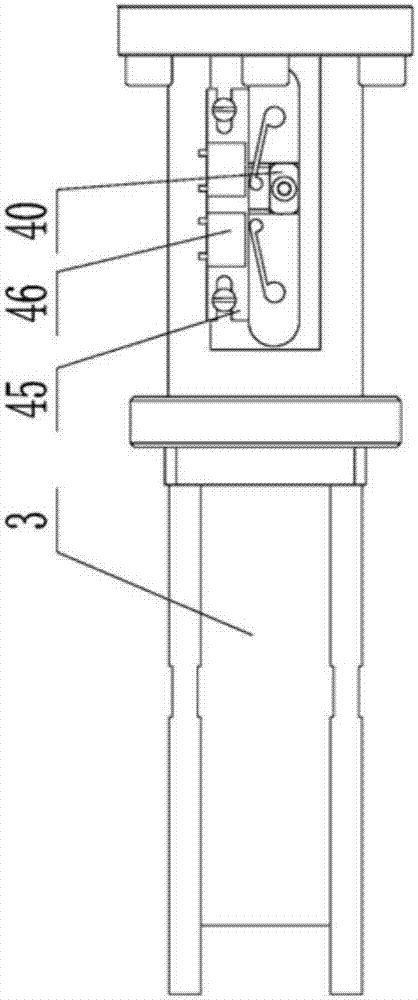

[0033] The following combination Figure 1~18 , the content of the present invention will be described in detail through specific embodiments. The double-bore microelectrode pusher includes a drive assembly, a bore arm assembly, a spring rod assembly and a measuring arm assembly assembled in sequence. The drive assembly is provided with a switch assembly, and the spring rod assembly is provided with a pole plate assembly. Wherein, the driving assembly includes a motor housing 1, a number of struts 14 limited in the motor housing 1, a motor 3 limited between the struts 14, a lead screw 34 installed at the output end of the motor 3, and a screw 34 limited in the lead screw. The screw nut I 41 on the bar 34, the switch assembly that is limited on the leading screw 34, the joint 37 that is sleeved on the leading screw 34 outside, one end of the joint 37 is equipped with some pins 6 with wires at the ends, and the pins 6 Circumferentially distributed on the outside of the leading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com