High-angle well/horizontal well formation resistivity anisotropy correcting method

A technology of formation resistivity and anisotropy, applied in wellbore/well components, earth-moving drilling, etc., can solve discrete, log curve continuity and heterogeneity violations, and cannot use logging data to explain point by point And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

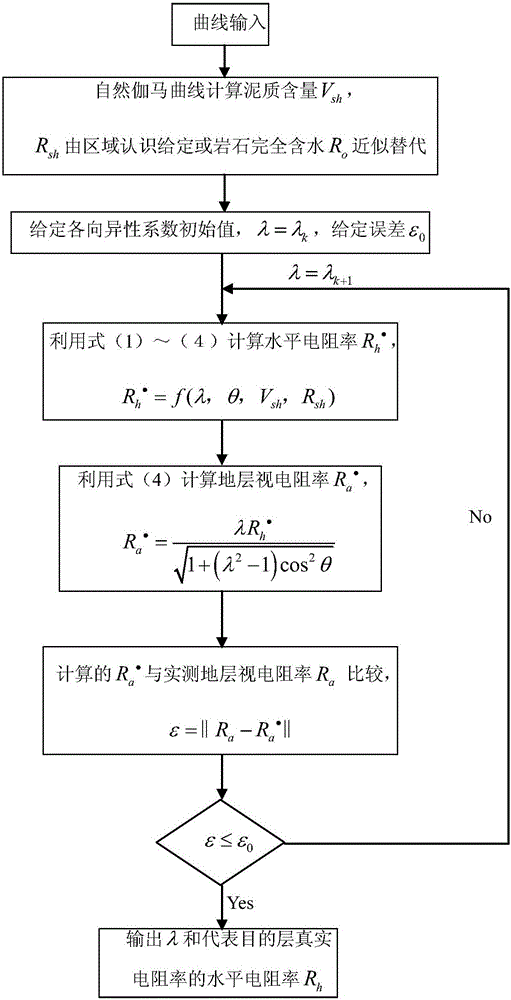

Method used

Image

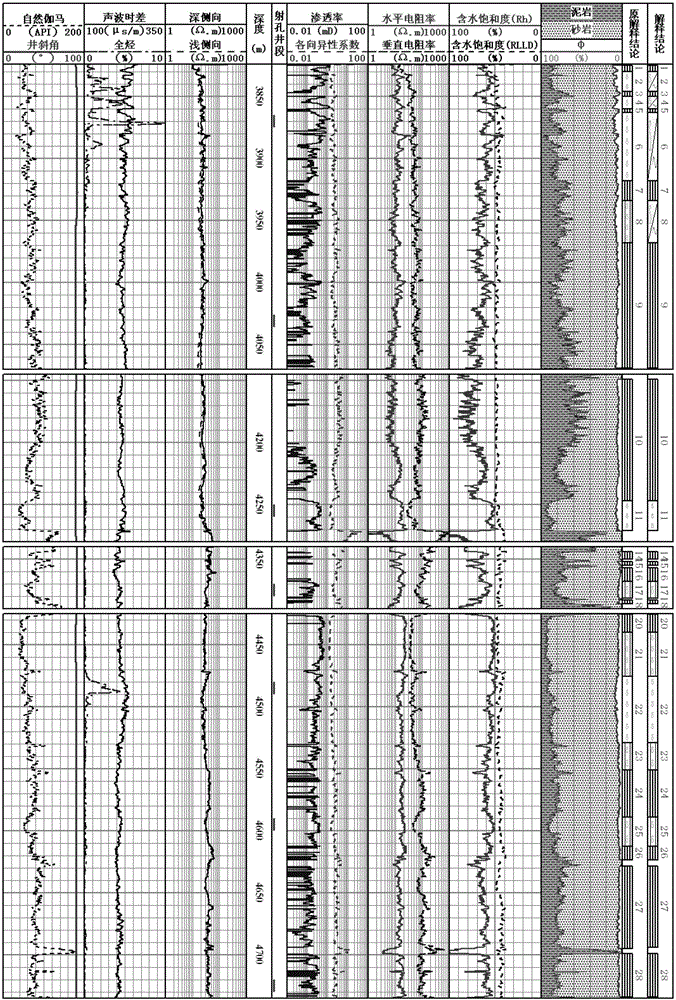

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

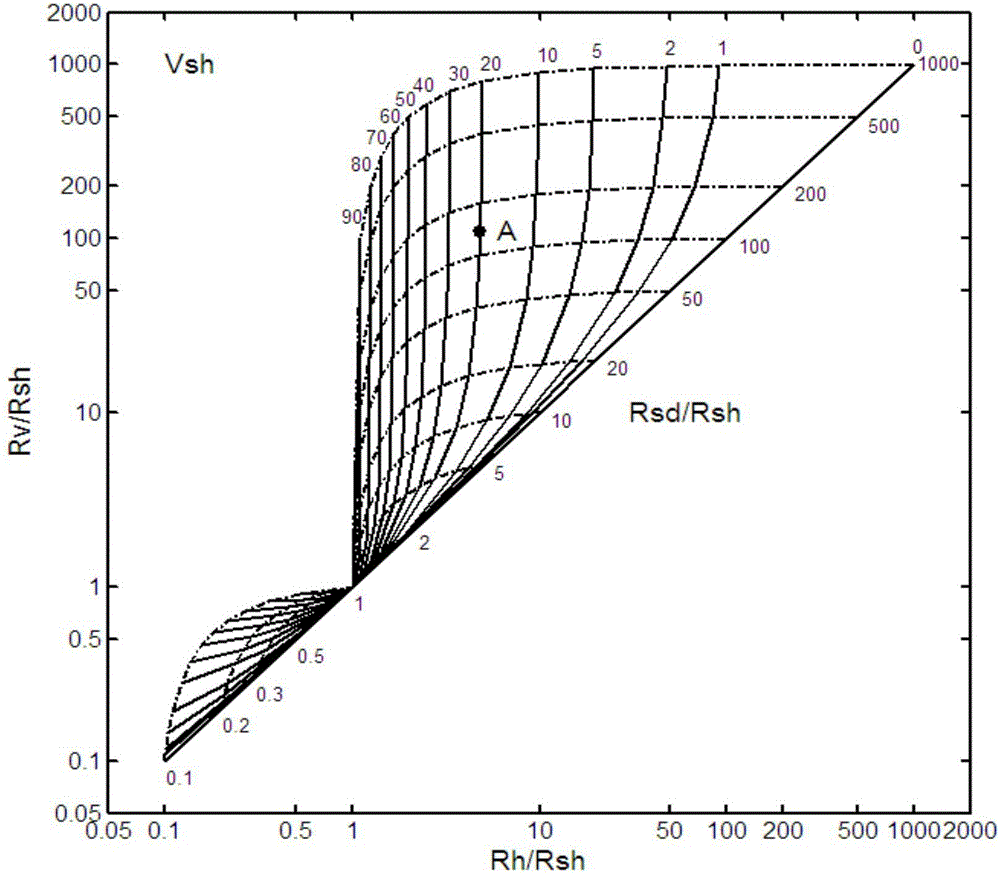

[0042] In the present invention, formation resistivity anisotropy can be divided into macroscopic anisotropy and microscopic anisotropy, and the parameters describing formation resistivity anisotropy mainly include, horizontal resistivity R h , vertical resistivity R v and the resistivity anisotropy coefficient λ. In highly deviated / horizontal wells, the formation resistivity R measured by the tool a is the horizontal resistivity R h and vertical resistivity R v comprehensive reflection.

[0043] When the wellbore trajectory of the horizontal well is closer to the formation layer, that is, the distance between the wellbore trajectory of the horizontal well and the formation layer is less than the detection depth of the logging tool, or intersects with the formation layer, the logging tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com