Lithium iron phosphate, preparation method thereof and lithium ion battery

A lithium iron phosphate and lithium source technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of many heterogeneous phases and low compaction density of lithium iron phosphate, and achieve the effect of improving the compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

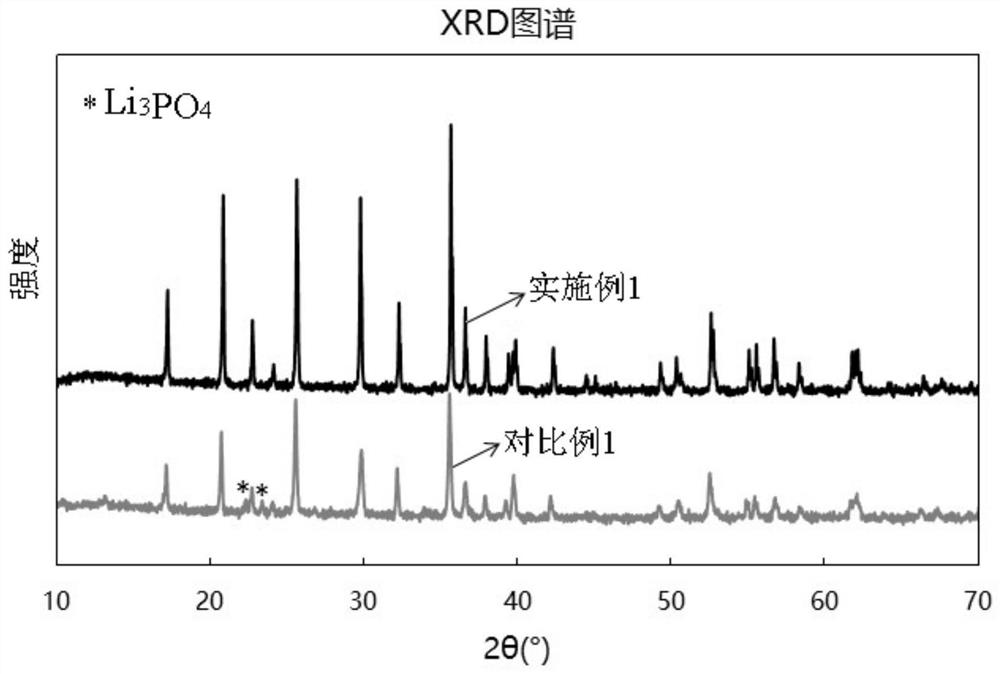

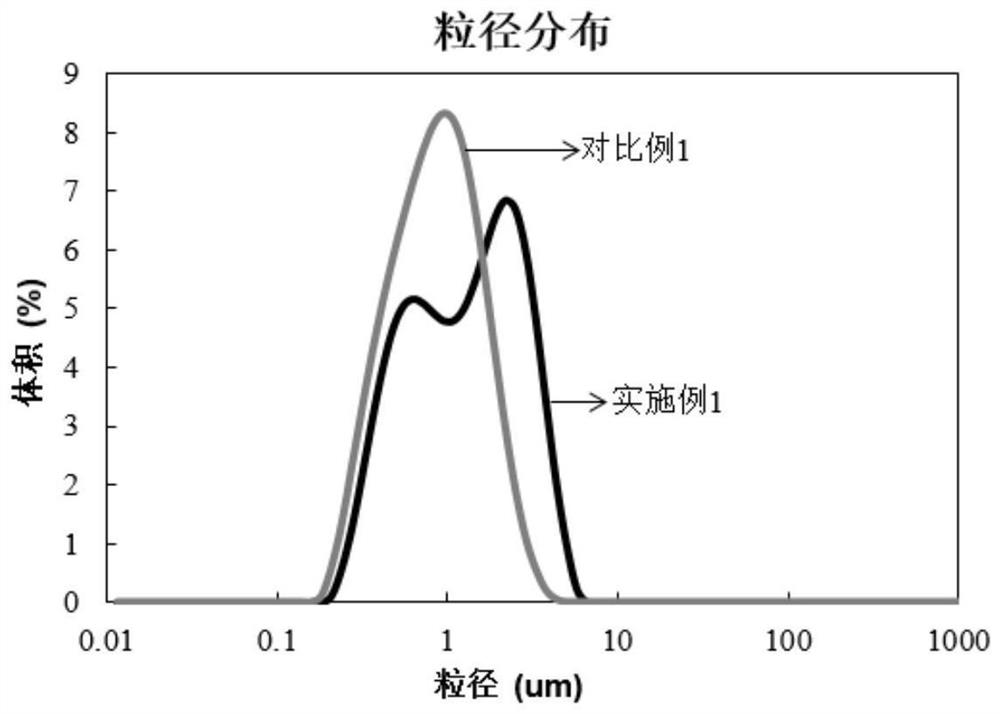

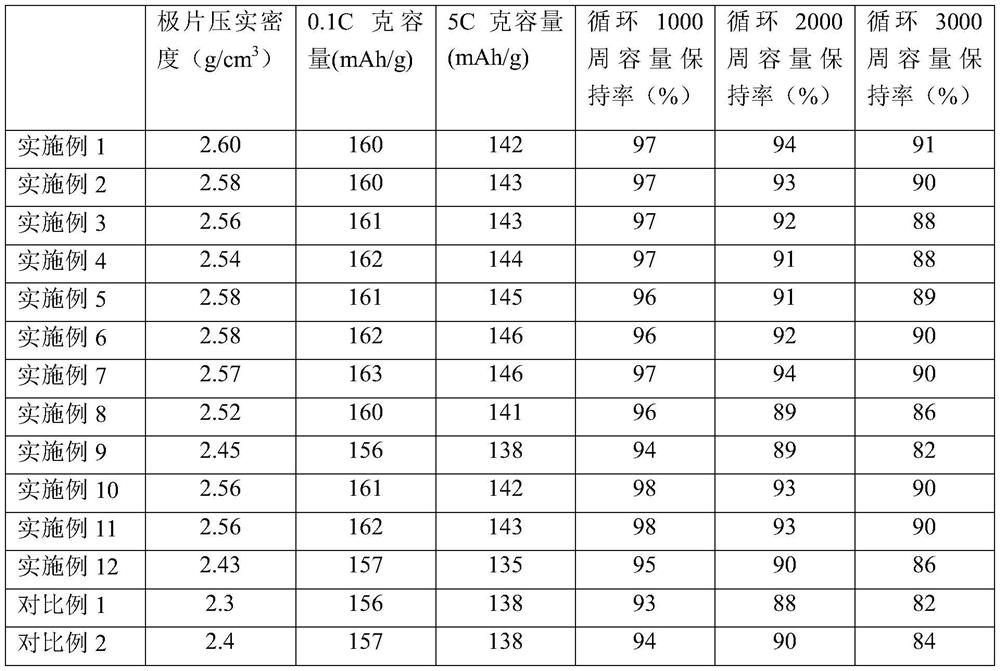

[0022] As described in the background art, the lithium iron phosphate produced by the existing method has the problems of low compaction density and many impurity phases. In order to solve the above technical problems, the present application provides a method for preparing lithium iron phosphate, the method for preparing lithium iron phosphate includes: mixing a soluble lithium source compound, a soluble ferrous iron source compound and water to obtain a first raw material solution; After the first raw material liquid is raised to a predetermined temperature, in the first inert atmosphere and acidic conditions, the aqueous solution of the soluble phosphorus source compound is mixed with the first raw material liquid by spraying, and the first hydrothermal synthesis reaction is carried out to obtain A first hydrothermal synthesis product system containing lithium iron phosphate; under a second inert atmosphere, the first hydrothermal synthesis product system is subjected to a s...

Embodiment 1

[0039] A preparation method of lithium iron phosphate with high compacted density, comprising:

[0040] Step 1, raw material liquid preparation:

[0041] In a 100L reactor, add 5mol lithium nitrate, 5mol ferrous nitrate, 0.01mol polyvinylpyrrolidone, dissolve in 80L deionized water, stir until completely dissolved, add sodium hydroxide to adjust the pH value to 6.5, and obtain a clear solution (No. - raw material solution); feed high-purity N 2 , after removing the air in the kettle, seal it, continue to stir and heat to 100°C, the heating rate is 5°C / min; dissolve 5mol ammonium dihydrogen phosphate in 20L deionized water, add sodium hydroxide to adjust the pH value to 6.5, and obtain phosphorus source solution.

[0042] Step 2, the first hydrothermal synthesis reaction:

[0043] With the above reaction kettle kept stirring rapidly, inject the phosphorus source solution into the reaction kettle at a speed of 1.0L / min, and keep it warm at 100°C for 3h, and cool to below 50°C...

Embodiment 2

[0047] A preparation method of lithium iron phosphate with high compacted density, comprising:

[0048] Step 1, raw material liquid preparation:

[0049] In a 100L reactor, add 6mol lithium nitrate, 6mol ferrous nitrate, 0.01mol polyvinylpyrrolidone, dissolve in 80L deionized water, stir until completely dissolved, add sodium hydroxide to adjust the pH value to 6.5, and obtain a clear solution (No. - raw material solution); feed high-purity N 2 , after removing the air in the kettle, seal it, continue to stir and heat to 100°C, the heating rate is 5°C / min; dissolve 6mol ammonium dihydrogen phosphate in 20L deionized water, add sodium hydroxide to adjust the pH value to 6.5, and obtain phosphorus source solution;

[0050] Step 2, the first hydrothermal synthesis reaction:

[0051] With the reactor kept stirring rapidly, inject the phosphorus source solution into the reactor at a rate of 1.0 L / min, and keep it at 100°C for 3 hours, and cool to below 50°C after the reaction is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com