A system and method for large-scale and high-precision online monitoring of shield tunnel misalignment

A shield tunnel, high-precision technology, applied in the system field of monitoring shield tunnel misalignment, can solve the problems of easy shear deformation at joints, short construction time, small environmental impact, etc., to achieve strong applicability and marketability. Competitiveness, improving the level of safety monitoring, and the effect of strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

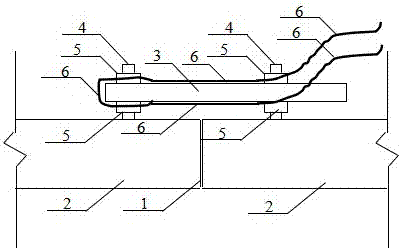

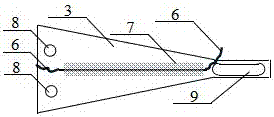

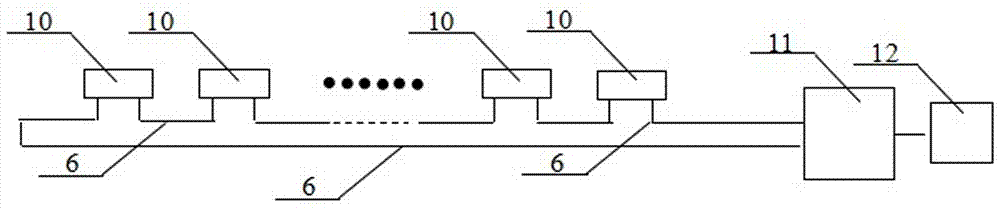

[0032] figure 1 It is a structural representation of the deformation sensing device of the present invention Figure 1 ; figure 2 It is a structural representation of the deformation sensing device of the present invention Figure II ; image 3 It is a schematic diagram of the connection of each component of the present invention;

[0033] Such as image 3 As shown: this embodiment is a system capable of large-scale and high-precision online monitoring of shield tunnel misalignment, including several deformation sensing devices 10, and several deformation sensing devices 10 pass through optical fiber sensing circuits and distributed optical fiber demodulators 11 is connected, and the distributed optical fiber demodulator 11 is connected with the computer 12, such as figure 1 and 2 As shown: the deformation sensing device 10 includes a deformation beam body 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com