A drum internal operation safety protection system and method

A technology of rollers and safety doors, applied in closed-circuit television systems, electrical transmission signal systems, computer components, etc., can solve problems such as low protection level of safety limit switches, accelerated devices, aging, etc., to improve the level of safety monitoring and improve The effect of reliability and timeliness

Active Publication Date: 2022-05-31

CHINA TOBACCO ANHUI IND CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The protection level of this safety limit switch is not high, and it will accelerate the aging of the device in a harsh environment for a long time, causing the floating point of the safety door limit switch to be in a conducting state. If the maintenance is not timely, there will be safety hazards; plus the site environment and personnel safety Consciousness is different, there will be perfunctory situations, which will lead to safety problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

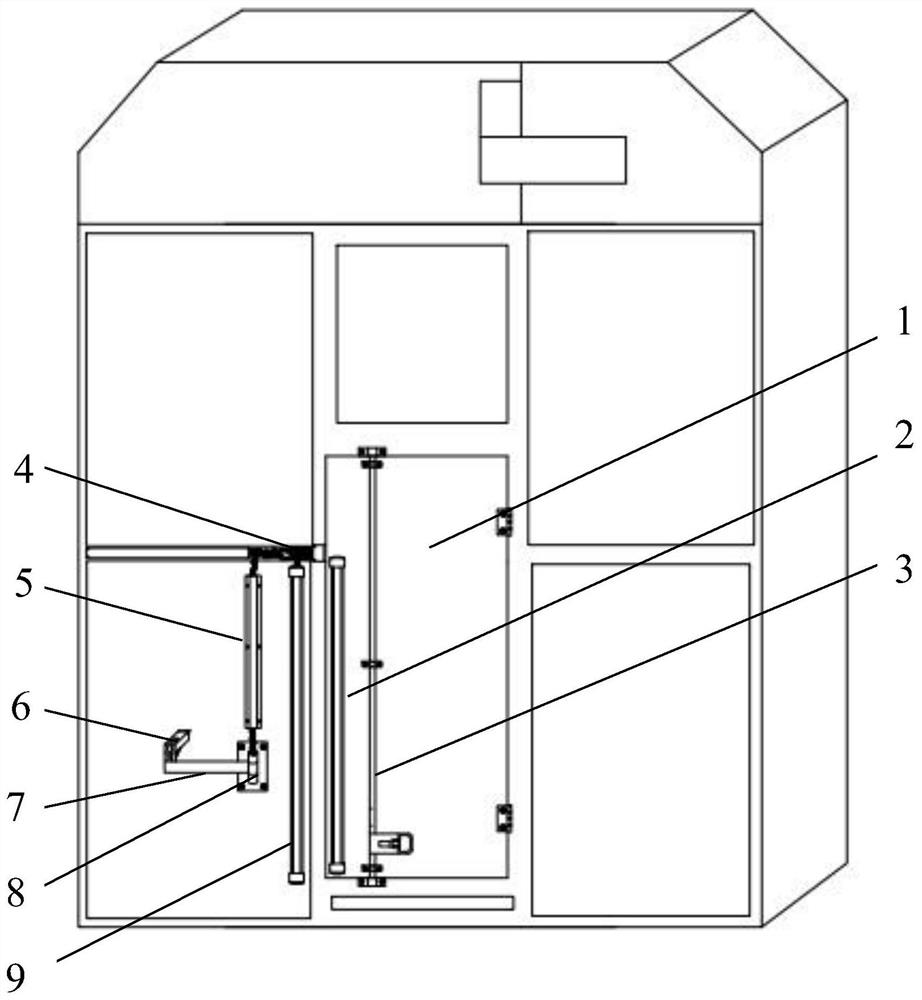

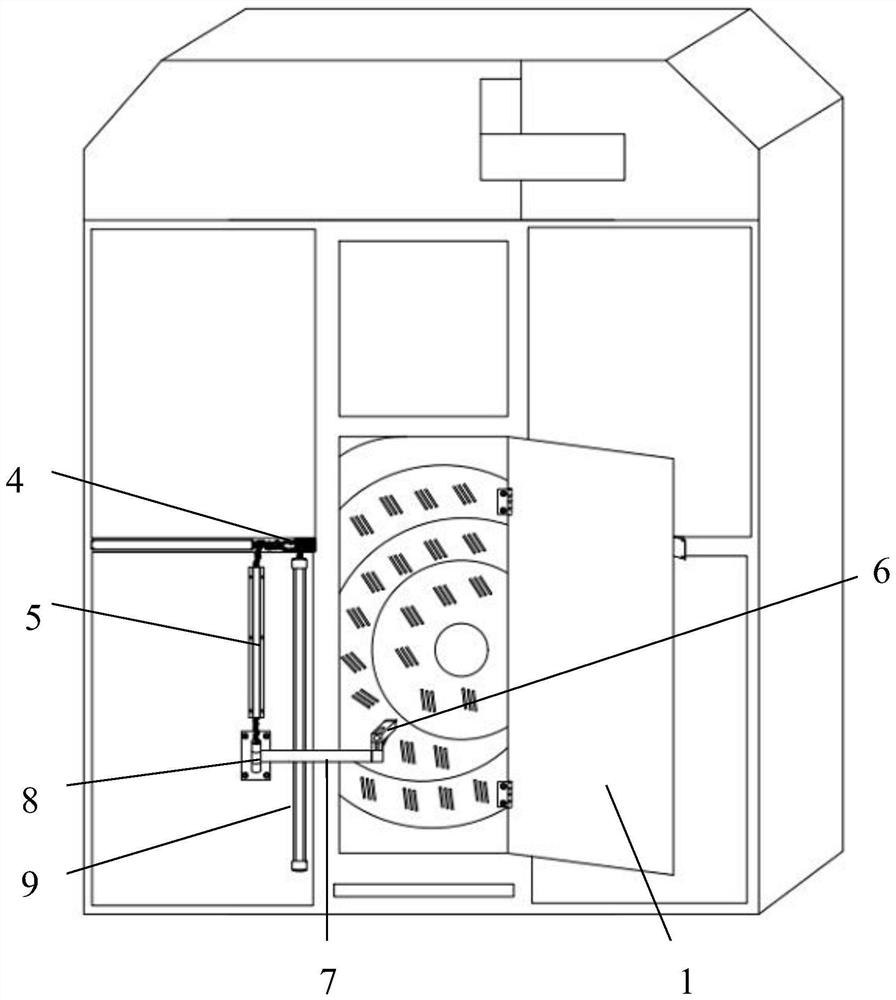

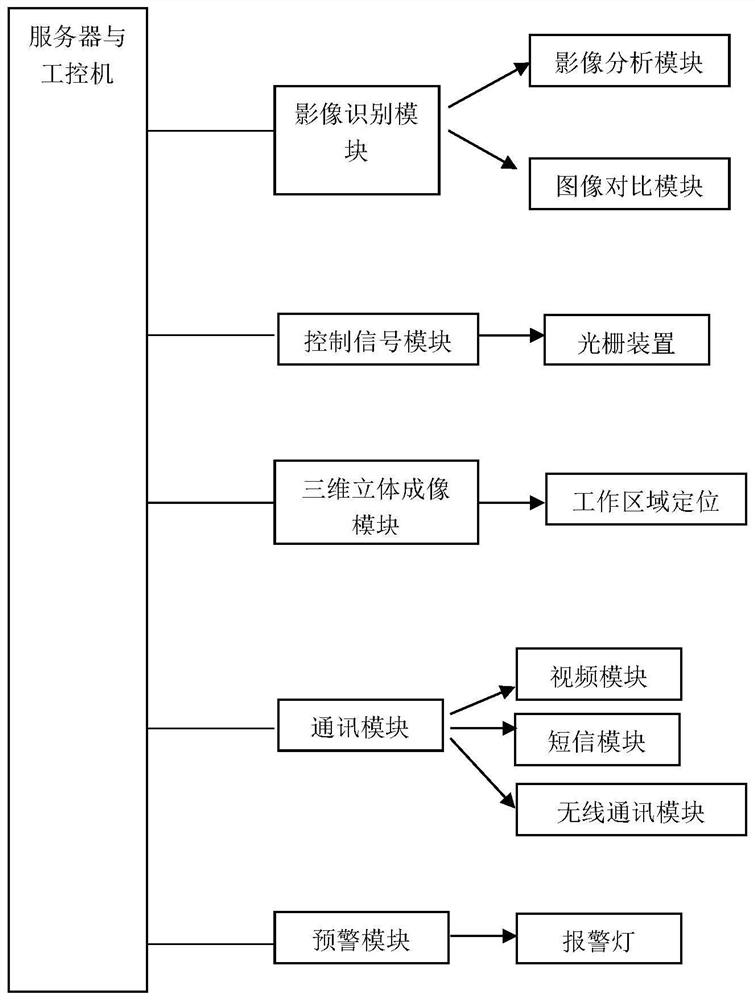

The invention discloses a safety protection system and method for internal operation of a drum. The system includes a terminal, a server, an industrial computer, and a database; System computing and information processing; among them, the 3D imaging module is used to build a 3D model of the external features of the drum; the database is used to locate the label position information of the staff; the industrial computer is used to obtain the on-off signal of the limit switch of the drum safety door and the grating device The detection signal; the terminal is used to obtain the image of the staff in the drum; the image recognition module is used to enter the simulated image of the staff in the three-dimensional drum; the image comparison module is used to identify dangerous postures; the early warning module is used to realize the local sound and light alarm. The invention can realize functions such as monitoring, safety protection and early warning for the staff in the drum, thereby improving the personal safety protection level of the drum.

Description

A safety protection system and method for internal operation of a drum technical field The present invention relates to the technical field of tobacco processing equipment, more specifically to a safety protection system for internal operation of a drum systems and methods. Background technique In the tobacco industry, maintenance and repair operations are carried out to the drum equipment, usually only one person operates, and there is a lack of personnel supervision. Governor. The original drum of the silk-making workshop adopts socket-type safety limit switch or the on-off signal of the travel switch to monitor the status of the safety door. The protection level of this safety limit switch is not high, and the aging of the device is accelerated in a harsh environment for a long time, resulting in the safety door limit opening. The floating-point switch is in an on state, if the maintenance is not timely, there will be potential safety hazards; in addition, the si...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G08B7/06G08B25/10H04N7/18G06F16/583G06V40/10G06V10/44

CPCG08B25/10G08B7/06G06F16/5854H04N7/18G06V40/103G06V10/44

Inventor 周宣曹琛宣义友徐鹏

Owner CHINA TOBACCO ANHUI IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com