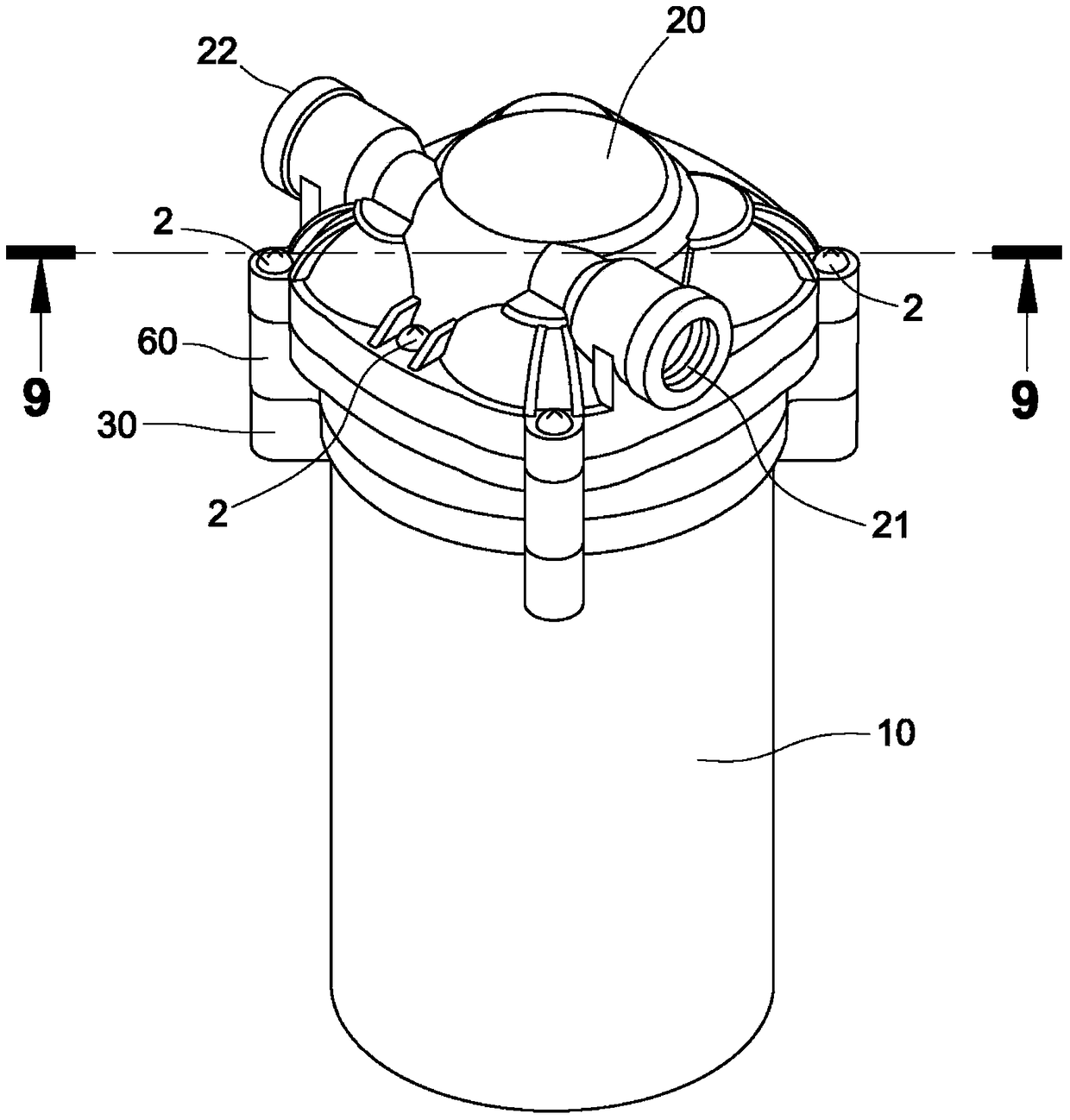

Shock-absorbing structure of four-pressure chamber diaphragm pump

A four-pressure chamber, diaphragm pump technology, applied to the components, pumps, pump components, etc. of the pumping device for elastic fluid, can solve the problems of annoying, limited shock absorption, mutual looseness, etc. Vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

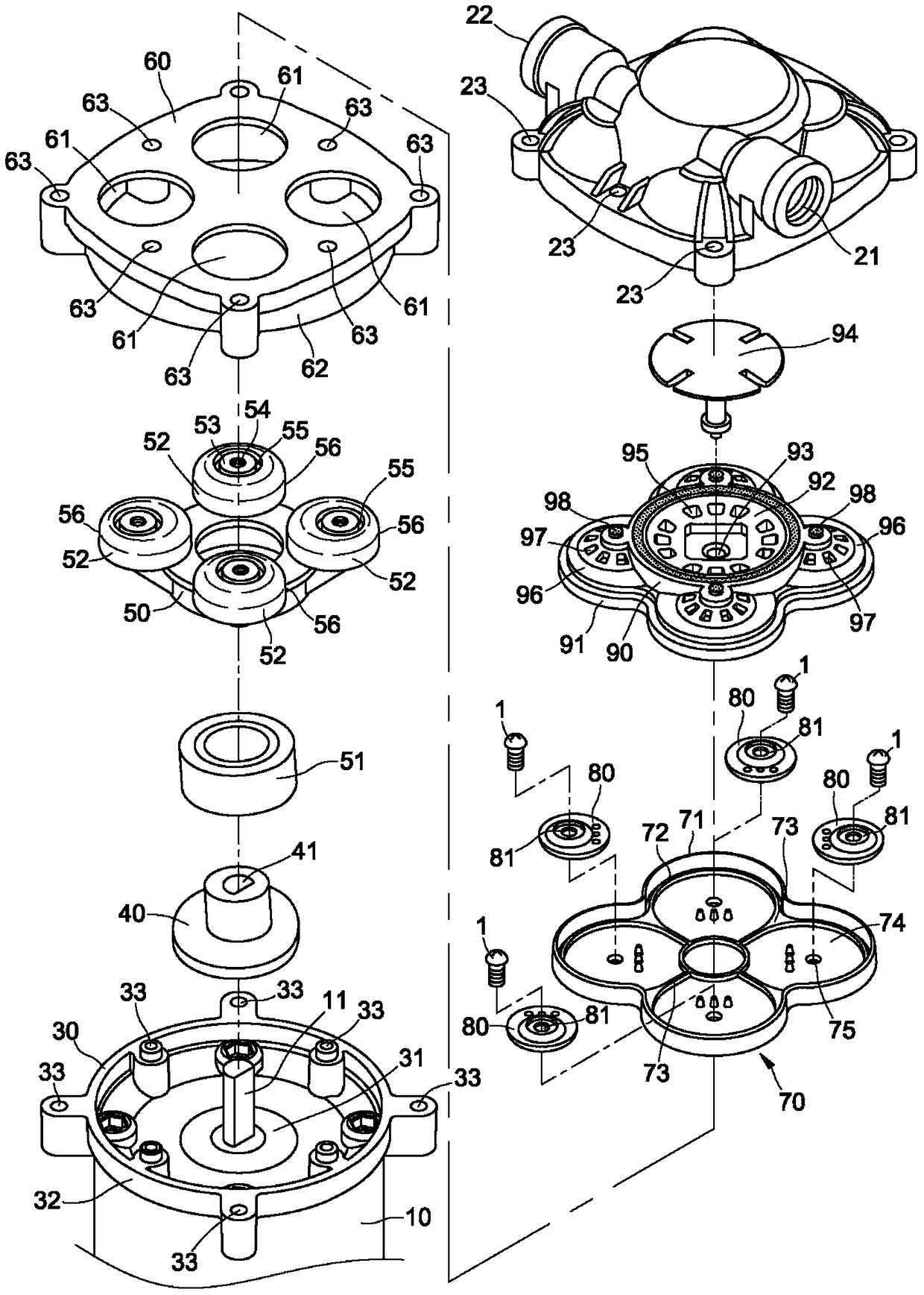

Embodiment Construction

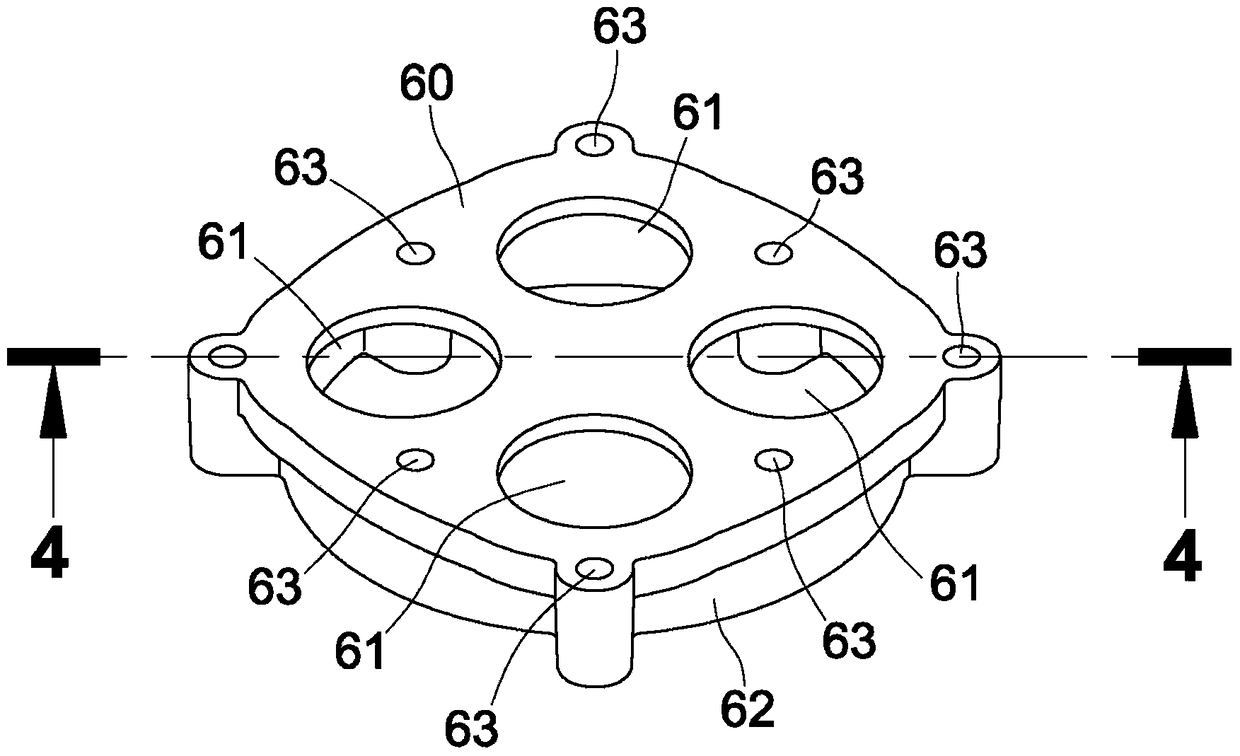

[0155] Such as Figure 15 to Figure 22 As shown, it is the first embodiment of the damping structure of the four booster chamber diaphragm pump of the present invention, which is to set an arc-shaped concave downward around the periphery of each actuating hole 61 on the top surface of the pump head seat 60. groove 65, and on the bottom surface of the diaphragm 70 corresponding to each arc-shaped groove 65 position, an arc-shaped protrusion 77 is protruded downward (such as Figure 20 and Figure 21 As shown), after the bottom surface of the diaphragm 70 and the top surface of the pump head seat 60 are attached to each other, the four arc-shaped protrusions 77 on the bottom surface of the diaphragm 70 are completely embedded in the four arc-shaped concave holes on the top surface of the pump head seat 60. In the slot 65, a short arm length L2 is formed between the arc-shaped protrusion 77 on the bottom surface of the diaphragm 70 and the positioning protrusion 76 (such as Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com