Energy-efficient automobile hydraulic coupler

A hydraulic coupling, high-efficiency and energy-saving technology, applied in the direction of clutches, clutches, fluid clutches, etc., can solve problems such as waste of energy, complicated disassembly, and inconvenient maintenance, so as to improve work efficiency, facilitate disassembly and maintenance, and facilitate assembly and disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

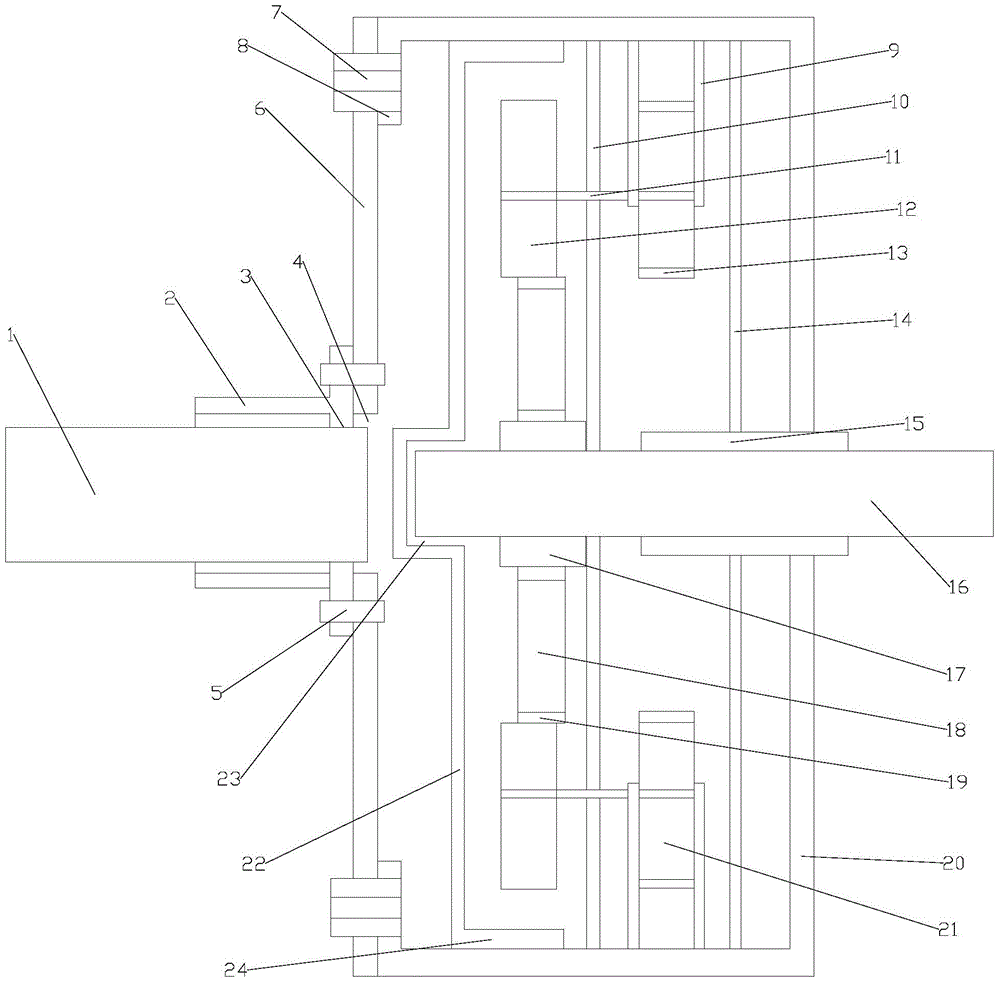

[0017] This embodiment includes a coupler bottom case 20 and a coupler end cover 6, one side of the coupler bottom case 20 is open and the interior is hollow, a fixing plate 8 is arranged at the opening of the coupler bottom case 20, and the coupler end cover 6 and the fixing plate 8 Fixedly connected by bolt 7, a limit sleeve 2 is provided on one side of the coupler end cover 6, the limit sleeve 2 and the coupler end cover 6 are fixedly connected by screws 5, the limit sleeve 2 is provided with a round hole 3, and the coupler The bottom shell 20 is provided with a through groove 4, the limit sleeve 2 is provided with an input shaft 1, and the input shaft 1 passes through the round hole 3, and the coupler bottom shell 20 is provided with a limit baffle 22, and the two ends of the limit baffle 22 are A supporting plate 24 is provided, and the supporting plate 24 is close to the inner wall of the coupler bottom case 20. A recessed part 23 is provided in the middle of the limit ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com