Novel automotive headlamp bulb

A technology for automobiles and front lighting, which is applied in the direction of headlights, motor vehicles, road vehicles, etc. It can solve the problems affecting the appearance quality of products, poor solder joint consistency, and complicated assembly process, so as to save labor costs and improve the appearance quality , The effect of simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

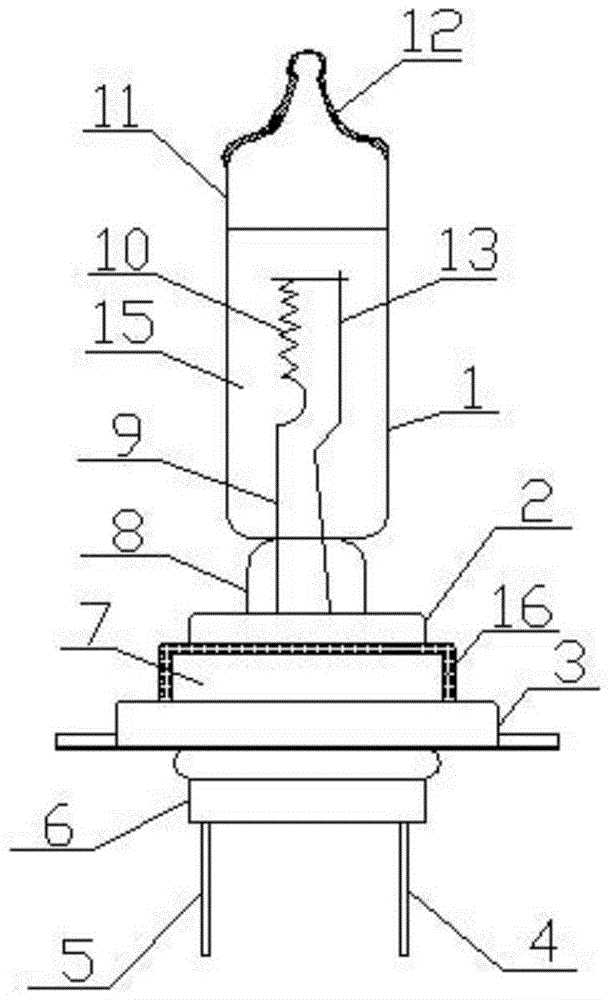

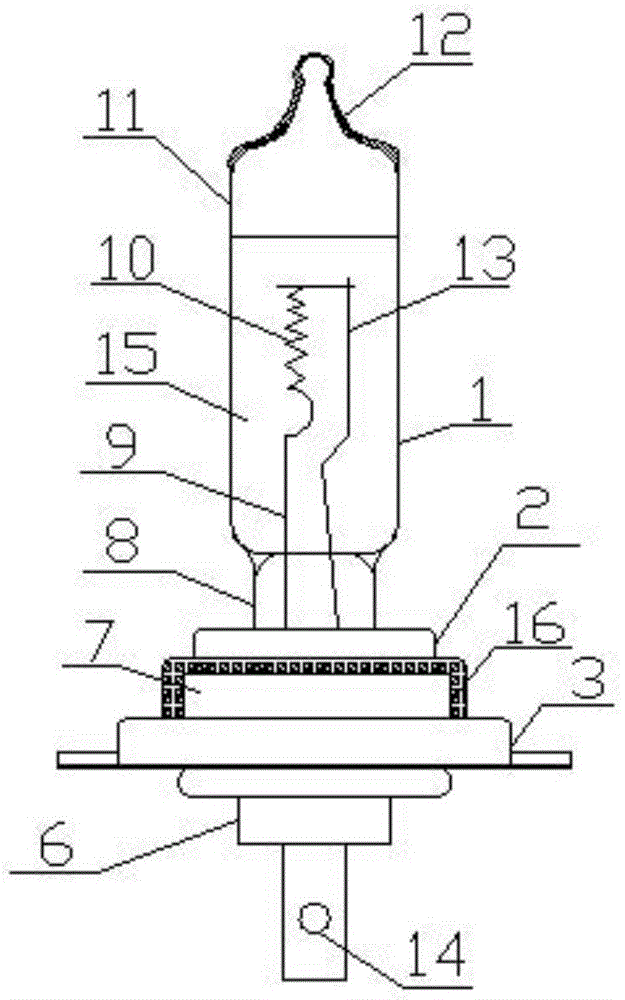

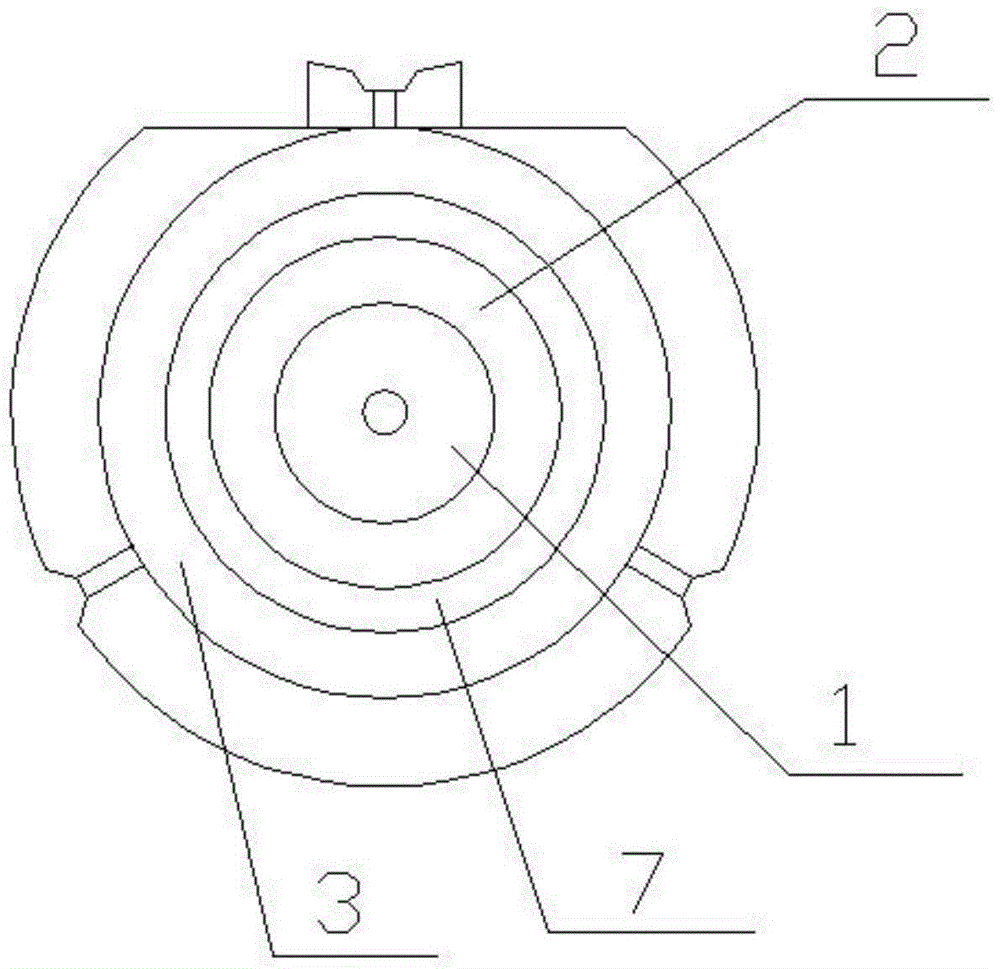

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a new type of automobile headlight bulb includes a hard glass wool bulb 1 and a glass wool bubble tip 11 arranged on the top of the hard glass wool bubble 1, and a high color temperature coating is arranged on the outer surface of the glass wool bubble tip 11 12. The thickness of the high color temperature coating 12 is 0.3-1.2mm, the positive electrode wire 13 and the negative electrode wire 9 are arranged inside the hard glass wool bulb 1, and the filament 10 is connected between the positive electrode wire 13 and the negative electrode wire 9, The hard glass wool 1 is provided with a cavity 15, and the cavity 15 is filled with xenon gas, which better improves the transmission of light in the hard glass wool 1, increases the brightness of the product, and further improve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com