Energy-saving high-efficiency inclined vanadium-nitrogen alloy furnace

A vanadium-nitrogen alloy and kiln technology, which is applied in the field of energy-saving and high-efficiency inclined vanadium-nitrogen alloy kilns, can solve the problem that tube furnaces and microwave ovens are not suitable for large-scale industrial production, and the gas in the kiln cannot be discharged in time, which affects the furnace and kiln. service life and other issues, to achieve the effect of improving the utilization rate of electric energy, improving the thermal cycle, and reducing the surface heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

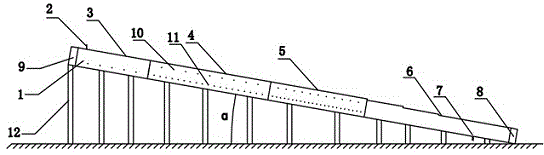

[0017] Please refer to figure 1 , The specific embodiment of the present invention, an energy-saving and efficient oblique vanadium-nitrogen alloy furnace, including a vanadium-nitrogen alloy furnace body, a smoke outlet, a low temperature section, a medium temperature section, a high temperature section, a cooling section, a nitrogen gas inlet, and a discharge port , Feed inlet, heating element, furnace inclined support frame; the vanadium-nitrogen alloy furnace body is sequentially provided with a low temperature section, a medium temperature section, a high temperature section and a cooling section; the heating element includes an upper heating element and a lower heating element, the upper part The heating element is arranged at the upper part of the intermediate charge main channel, and the lower heating element is arranged at the lower part of the intermediate charge main channel.

[0018] Please refer to figure 1 , The feed port is set at the front end of the low temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com