Visible light auxiliary calibration type laser transmitter and calibration method thereof

A laser transmitter and laser emission technology, applied in the laser field, can solve the problems of low precision, complexity, inconvenient operation, etc., and achieve the effects of convenient operation, scientific rationality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

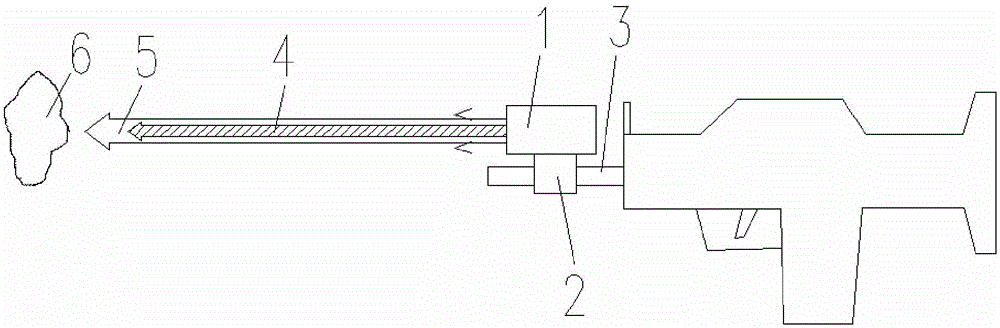

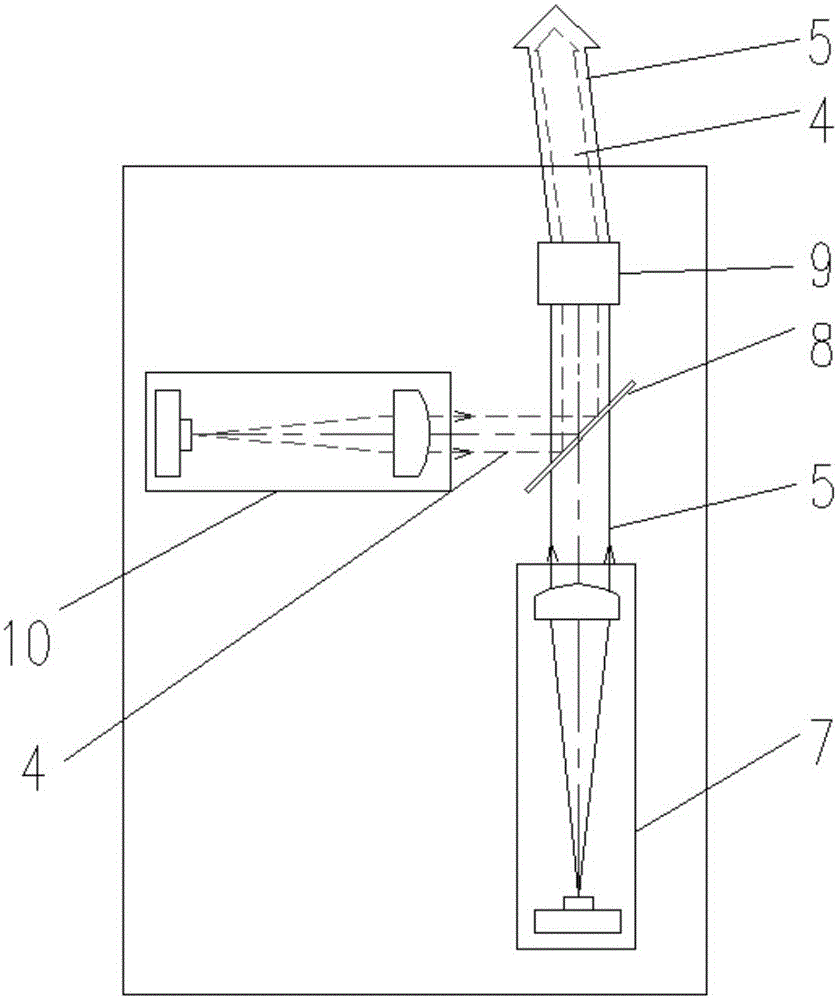

[0027] This embodiment provides a visible light assisted calibration type laser transmitter, the structure is as follows figure 1 , figure 2 As shown, it includes a gun barrel 3, and a laser transmitter 1 installed on the gun barrel 3 through a clamp 2. The laser transmitter 1 is provided with an infrared laser emitting device 7 and a visible laser emitting device 10, and the infrared laser emitting device 7 generates infrared Laser 5, visible laser emitting device 10 produces visible laser 4, laser transmitter 1 is also provided with a beam splitter 8 and an optical path adjustment mechanism 9, infrared laser 5 directly exits the laser transmitter 1 through the optical path adjustment mechanism 9, the visible laser 4 is reflected by the beam splitter 8 into the optical path adjustment mechanism 9 and then exits the laser transmitter 1.

[0028] The visible laser emitting device 10 is set vertically to the infrared laser emitting device 7, and the beam splitter 8 is set at a...

Embodiment 2

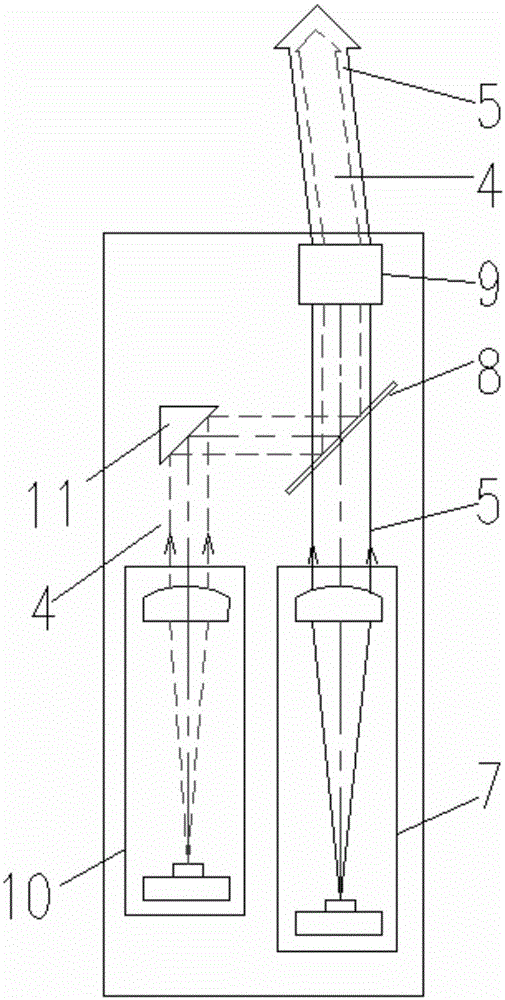

[0031] This embodiment provides a visible light assisted calibration type laser transmitter, the structure is as follows figure 1 , image 3 As shown, it includes a gun barrel 3, and a laser transmitter 1 installed on the gun barrel 3 through a clamp 2. The laser transmitter 1 is provided with an infrared laser emitting device 7 and a visible laser emitting device 10, and the infrared laser emitting device 7 generates infrared Laser 5, visible laser emitting device 10 generates visible laser 4, laser transmitter 1 is also equipped with a beam splitter 8 and an optical path adjustment mechanism 9, infrared laser 5 directly exits the laser transmitter 1 through the optical path adjustment mechanism 9, and visible laser 4 passes through The beam splitter 8 reflects into the optical path adjustment mechanism 9 and then exits the laser transmitter 1 .

[0032] The aforementioned visible laser emitting device 10 is arranged in parallel with the infrared laser emitting device 7. Whe...

Embodiment 3

[0035] This embodiment provides a calibration method for a visible light assisted calibration laser transmitter, such as figure 1 As shown, the specific steps are as follows:

[0036] Install the laser transmitter 1 firmly on the gun barrel 3 through the clamp 2;

[0037] Adjust the optical path adjustment mechanism 9 to synchronously adjust the composite beam of the visible laser 4 and the infrared laser 5, so that the optical axis of the visible laser 4 and the optical axis of the infrared laser 5 are output from the laser transmitter 1 in a common optical axis manner;

[0038] Turn on the visible laser 4 and adjust the visible laser 4 to the aimed target 6 to realize the calibration between the infrared laser 5 and the aiming point of the gun. After the calibration is completed, turn off the visible laser 4;

[0039] Simulate live ammunition shooting of guns for confrontation training.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com