Apparatus for detecting resistance welding of battery pack and method thereof

A welding detection and detection method technology, which is applied in the field of battery pack resistance welding welding detection devices, can solve problems such as prone to misoperation, potential safety hazards, and personal injury, and achieve the effects of avoiding misoperation, reliable detection, and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

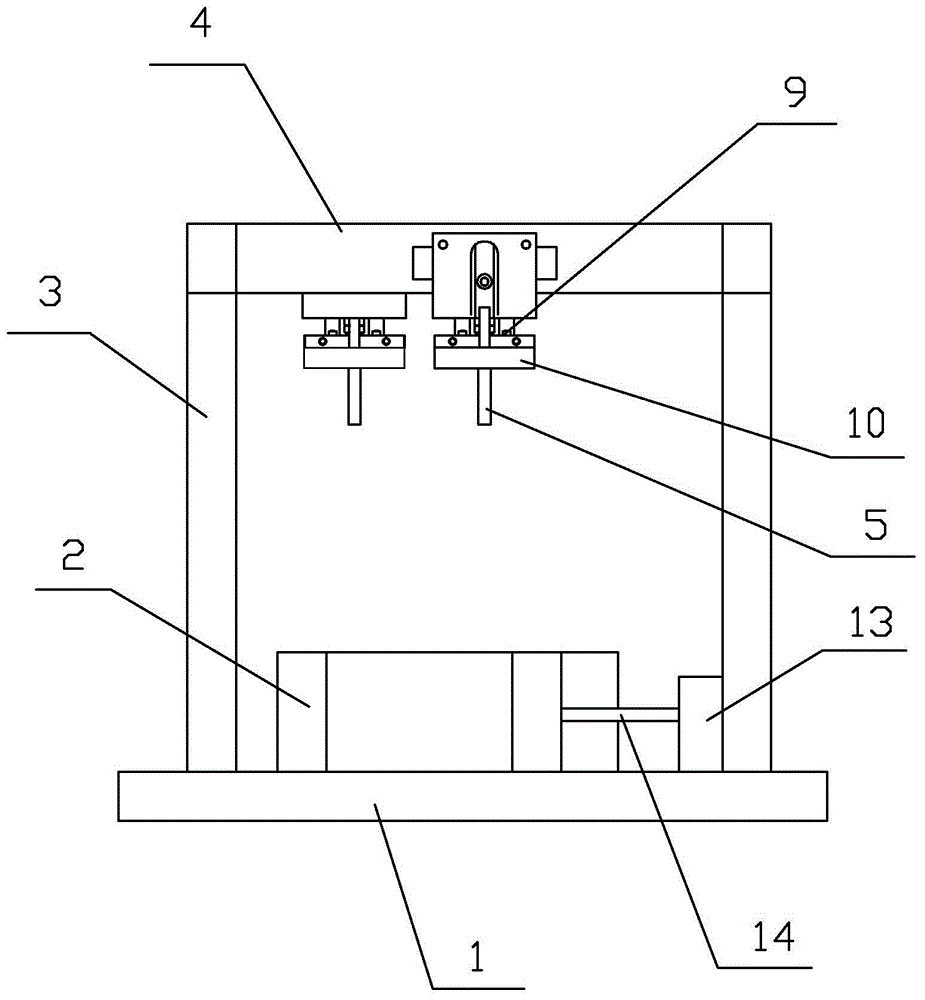

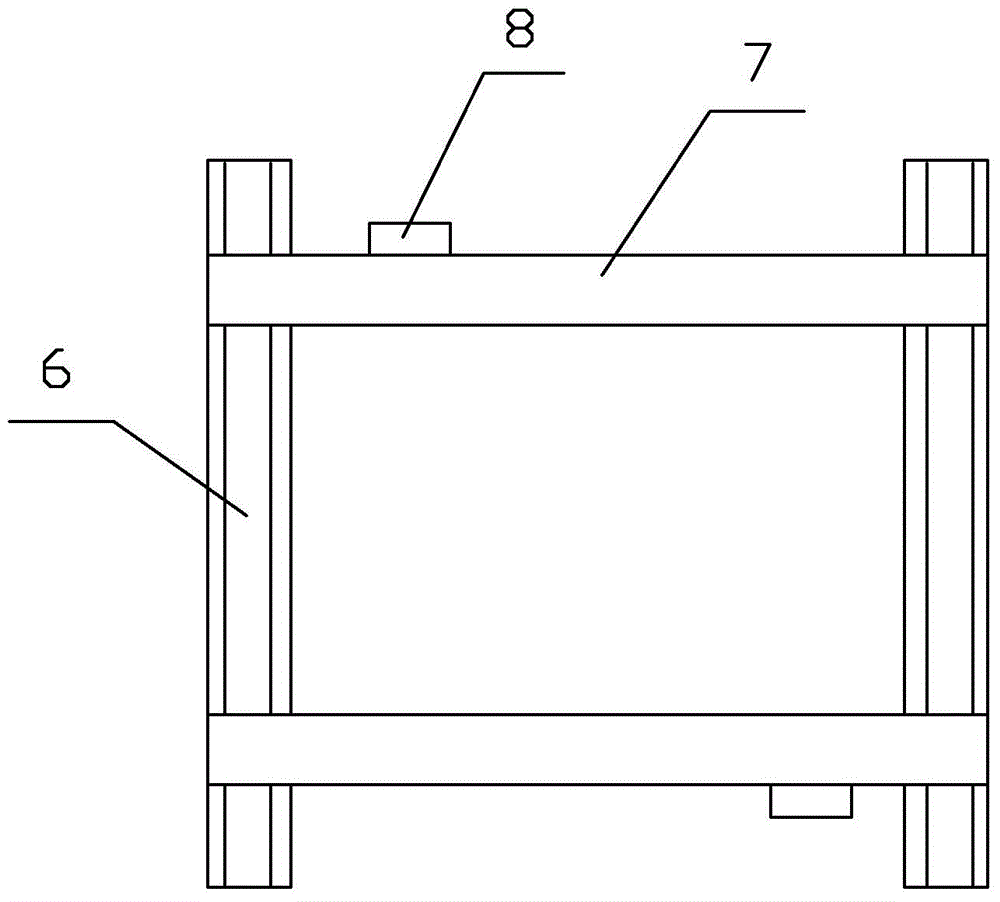

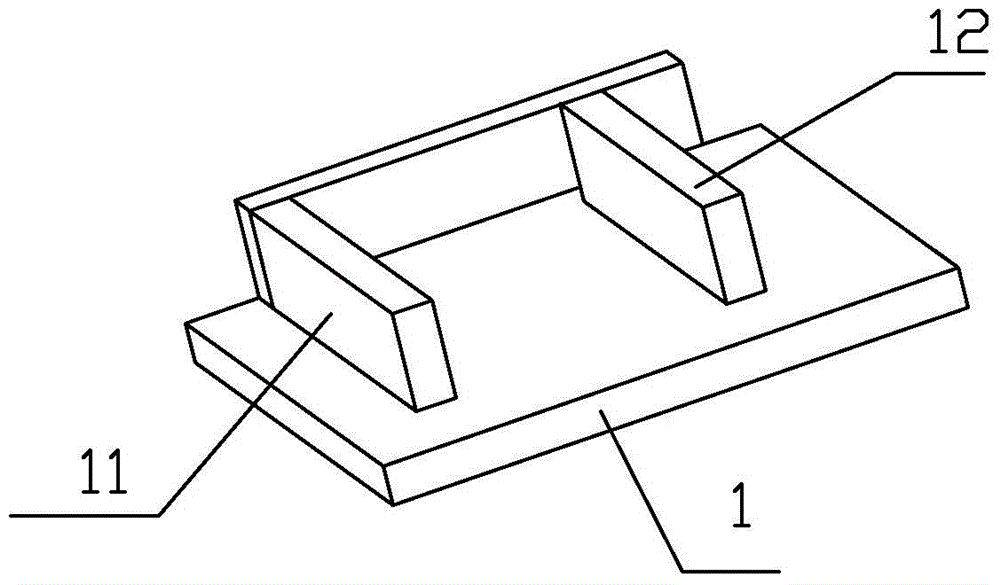

[0029] Embodiment: The resistance welding welding detection device of the battery pack of this embodiment, such as figure 1 As shown, it includes a base 1, a battery pack positioning frame 2, a fixed bracket 3, a translation mechanism 4, a lifting mechanism and two detection probes 5. The battery pack positioning frame 2, and a fixed bracket 3 are all installed on the base 1. The battery pack positioning frame 2 includes an L-shaped frame 11 formed by connecting the rear side plate and the left side plate and a slidable baffle 12, such as image 3 As shown, the L-shaped frame 11 is vertically installed on the base 1, the rear end of the baffle 12 and the rear side plate of the L-shaped frame 11 are slidably connected, and the right side of the base 1 is equipped with a pushing drive mechanism, which uses a horizontal air cylinder 13 , The piston of the horizontal cylinder 13 faces to the left, and a connecting rod 14 is connected between the piston of the horizontal cylinder 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com