Inorganic polarizing plate and production method thereof

A production method and polarizing plate technology, applied in optics, optical components, polarizing components, etc., can solve problems such as the absence of light sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0174] Examples of the present invention will be described below, but these examples should not be construed as limiting the scope of the present invention.

[0175] Electromagnetic field simulations were performed by rigorous coupled wave analysis using a Gsolver grating analysis simulator (GratingSolver Development Co.).

[0176] (simulation 1)

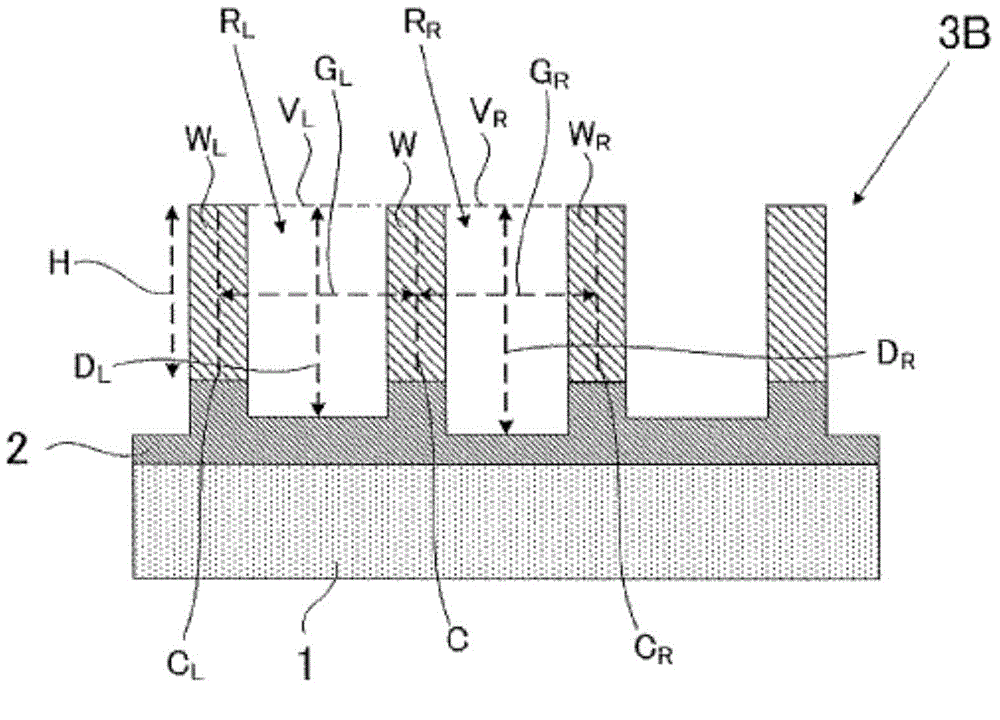

[0177] confirmed that due to changing the gap (G L ) and gap (G R ) The change in light transmittance caused by the difference between. Specifically, by changing the metal wire (W) and the metal wire (W L ) and the gap between the metal wire (W) and the metal wire (W R ), where these metal lines are composed of aluminum, to simulate the change in light transmittance.

[0178] A schematic cross-sectional view of the structure of the wire grid layer used for this simulation is in Figure 3A Presented in , simulated conditions and decrease in transmittance (decrease in transmittance) are presented below.

[0179] Table 1-1

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com