Meta material- microcavity composite structure and preparation method and use thereof

A composite structure and metamaterial technology, applied in the field of nanophotonics, can solve the problems of poor all-optical tunability, long response time, and small nonlinear refractive index of lithium niobate, so as to achieve reduced response time, simple manufacturing process, The effect of enhancing all-optical tunability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

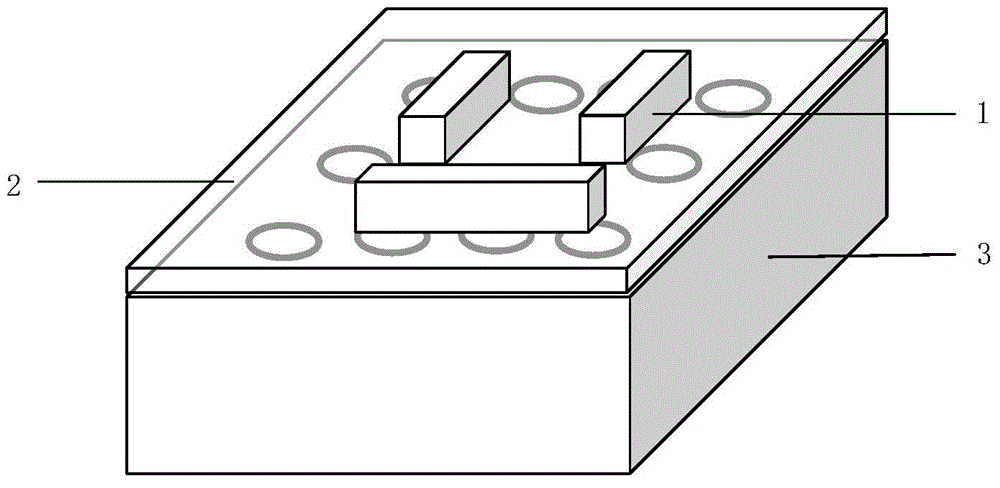

[0038] Such as figure 1 As shown, the metamaterial-microcavity composite structure of this embodiment includes from top to bottom: an upper layer 1, an intermediate layer 2, and a lower layer 3; wherein, the upper layer 1 is a metamaterial; the middle layer 2 is a two-dimensional material; the lower layer 3 is Optical microcavity; the metamaterial on the upper layer has multiple resonant units arranged periodically; the structure of the resonant unit is a broken semi-ring structure, and the material is gold; the two-dimensional material in the middle layer is tungsten disulfide; the optical The microcavity adopts photonic crystal microcavity.

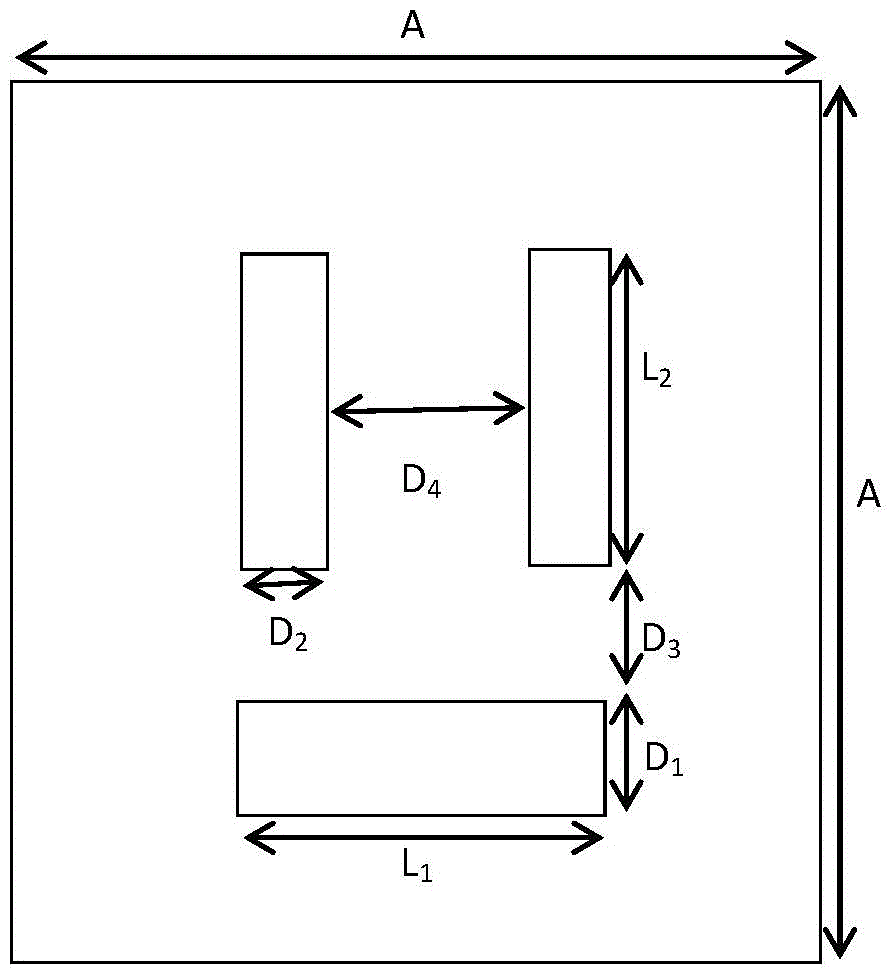

[0039] Such as figure 2 As shown, the broken half-ring structure includes an upper half and a lower half separated from each other; the lower half is a horizontal rectangular metal strip; the upper half is two symmetrical vertical rectangular metal strips. Among them, the period A of the resonance unit is 700nm; the length L of the h...

Embodiment 2

[0044] In this embodiment, the structure of the resonance unit is an asymmetric split-ring structure, such as Figure 6 As shown, it includes an upper half and a lower half separated from each other; the upper half is a ring-shaped metal strip, the lower half is a rectangular metal strip, and the lower half is smaller than the upper half. Among them, the period A of the resonance unit is 765nm; the lower part is a horizontal rectangular metal strip with a length l 1 595nm, width d 1 80nm; the upper part is a half-ring metal strip with a length of l 2 340nm, width d 2 80nm, the inner spacing d of the semi-ring metal strip 4 435nm; the distance d between the upper half and the lower half 3 60nm. Other structures are the same as in Embodiment 1.

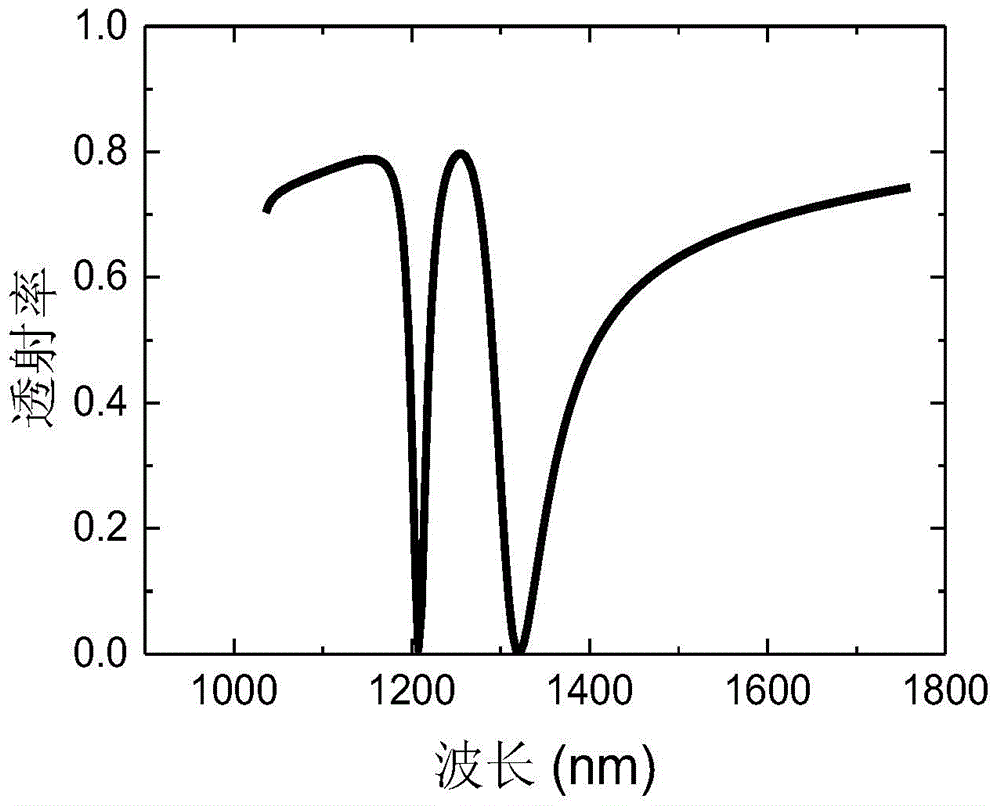

[0045] In this embodiment, the metamaterial is an asymmetric split-ring structure arranged periodically, and the probe light is vertically incident on the metamaterial, and the metamaterial is excited by infrared light to generate...

Embodiment 3

[0048] Such as Figure 10 As shown, the metamaterial-microcavity composite structure of this embodiment includes from top to bottom: an upper layer 1, an intermediate layer 2, and a lower layer 3; wherein, the upper layer 1 is a metamaterial; the middle layer 2 is a two-dimensional material; the lower layer 3 is Optical microcavity; the structure of the resonance unit in the upper layer is an asymmetric split-ring structure, including an upper half and a lower half separated from each other; the lower half and the upper half are respectively part circular, and the upper half The radius of the ring is larger than that of the bottom half.

[0049] The structure of the photonic crystal microcavity is as follows Figure 11 As shown, the photonic crystal microcavity in (a) is a point defect formed by removing an air hole in the periodically arranged air holes; the photonic crystal microcavity in (b) is a point formed by reducing the size of an air hole Defect composition; the cry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com