Method and device for simulating lifting process of large-sized equipment

A large-scale equipment and hoisting technology, which is applied in the direction of program control device, software simulation/interpretation/simulation, 3D modeling, etc., can solve the problems that cannot meet the high-precision simulation requirements of large-scale equipment, and the precision of large-scale equipment hoisting simulation is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

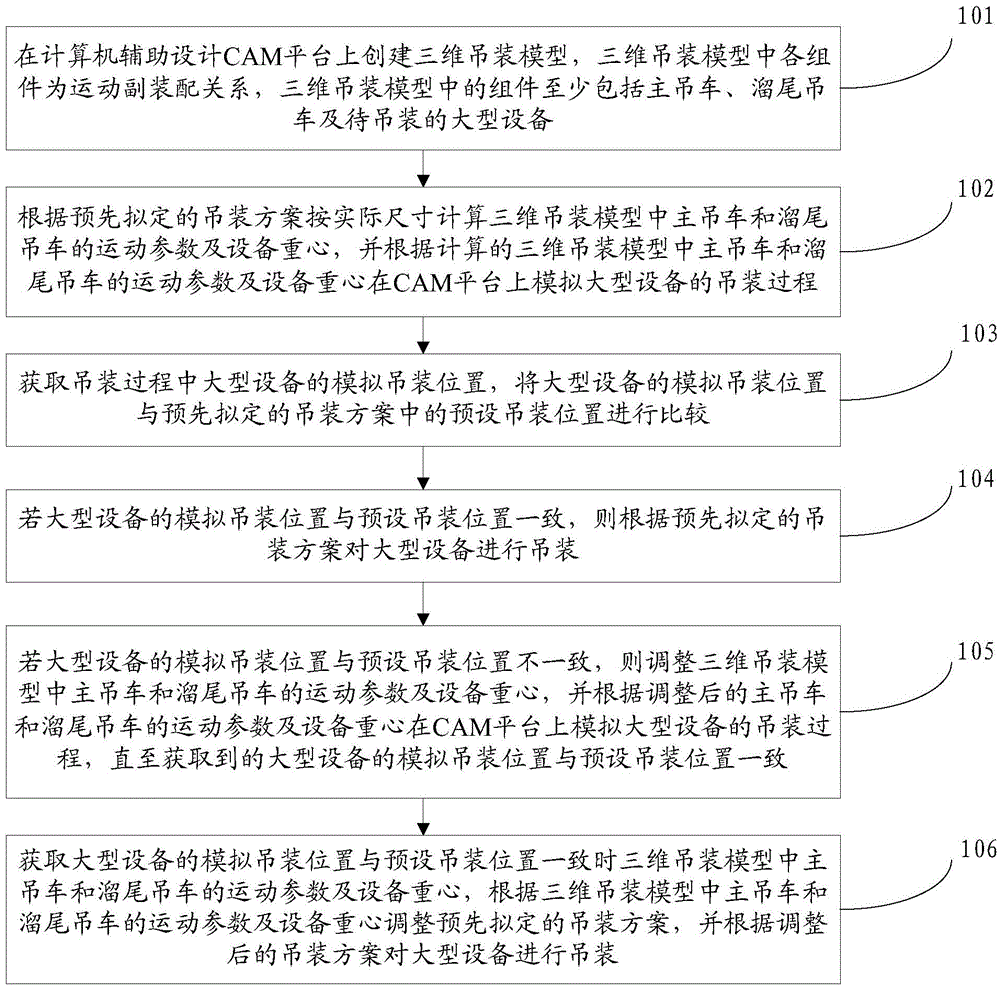

[0077] With the development of industrial technology, more and more large-scale equipment is used in industrial production, and it is difficult to hoist these large-scale equipment. The hoisting process of the equipment is carried out smoothly. For a method for simulating the hoisting process of large-scale equipment provided by the embodiment of the present invention, see figure 1 , the method flow provided by this embodiment includes:

[0078] 101: Create a three-dimensional hoisting model on the computer-aided design CAM platform. The components in the three-dimensional hoisting model are kinematic sub-assembly relationships. The components in the three-dimensional hoisting model include at least the main crane, the tail crane and the large equipment to be hoisted.

[0079] 102: Calculate the motion parameters and equipment center of gravity of the main crane and tail crane in the 3D hoisting model according to the actual size according to the pre-drawn hoisting scheme, and...

Embodiment 2

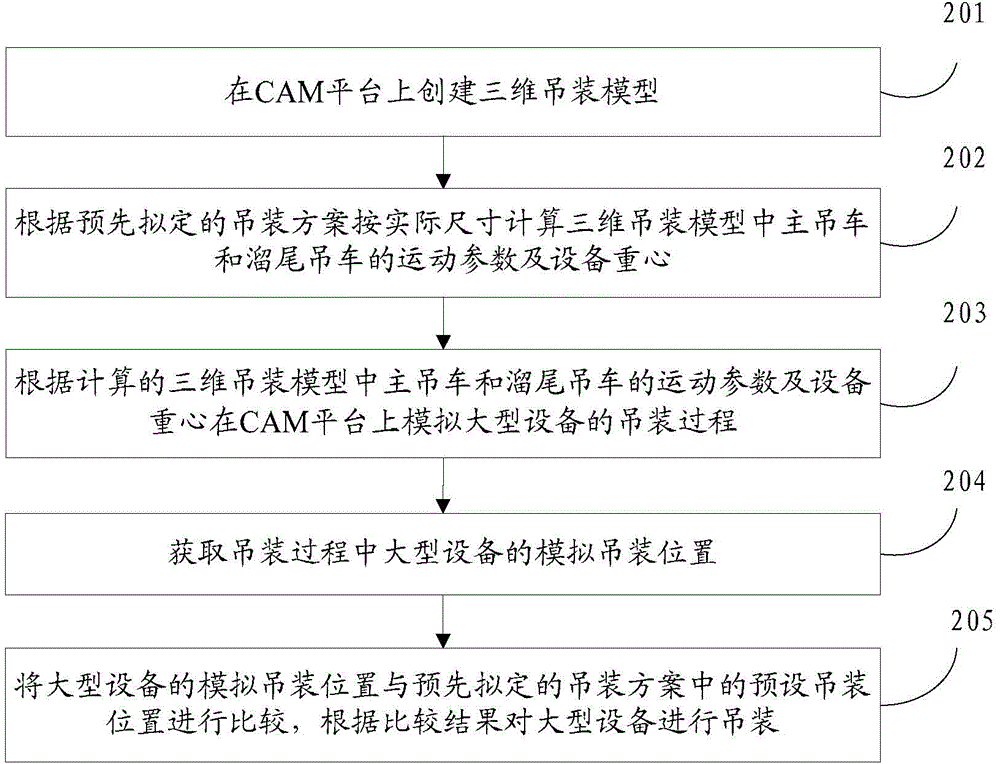

[0099] The embodiment of the present invention provides a method for simulating the hoisting process of large-scale equipment. For ease of understanding, the method for simulating the hoisting process of large-scale equipment provided by the embodiment of the present invention is explained in detail in combination with the content of the first embodiment above. see figure 2 , the method flow provided by the embodiment of the present invention includes:

[0100] 201: Create a three-dimensional hoisting model on a CAM platform.

[0101] About the way of creating 3D hoisting model on CAM platform, including but not limited to:

[0102] The first step is to determine the components used in the hoisting process according to the pre-drawn hoisting scheme;

[0103]For the first step, the hoisting scheme adopted in this embodiment is a two-vehicle rotary lifting scheme. When the two-vehicle rotary lifting is carried out, the main crane and the tail crane need to be used to cooperat...

Embodiment 3

[0165] see Figure 13 , the embodiment of the present invention provides a device for simulating the hoisting process of large equipment, the device includes:

[0166] The first creation module 1301 is used to create a three-dimensional hoisting model on the computer-aided design (CAM) platform. Each component in the three-dimensional hoisting model is a kinematic sub-assembly relationship. The components in the three-dimensional hoisting model include at least the main crane, the tail crane and the large equipment;

[0167] Calculation module 1302, used to calculate the motion parameters and center of gravity of the main crane and tail crane in the three-dimensional hoisting model according to the actual size according to the hoisting scheme drawn up in advance;

[0168] The simulation module 1303 is used to simulate the hoisting process of large-scale equipment on the CAM platform according to the motion parameters of the main crane and the tail crane in the calculated thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com