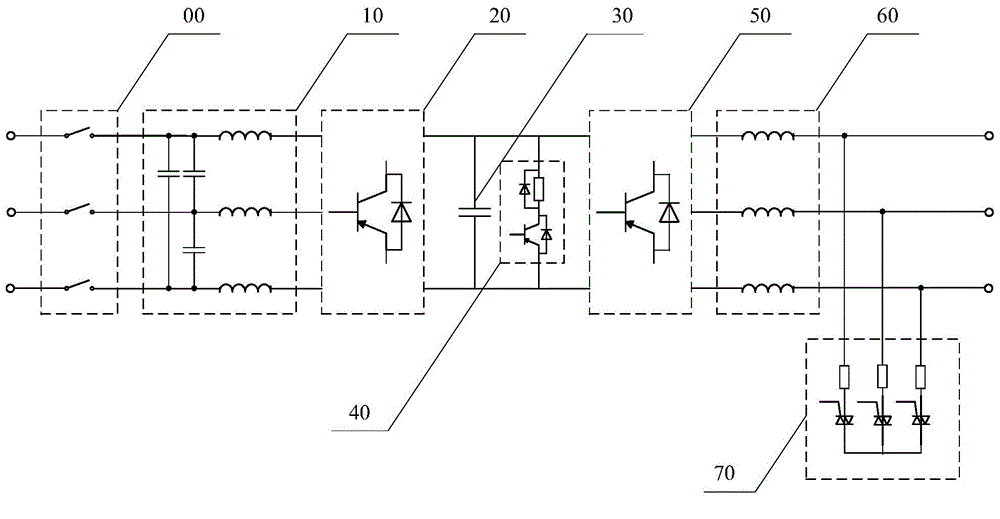

Method and device for discharging voltage of direct current bus capacitor in power electronic conversion system

A DC bus capacitor, power electronic conversion technology, applied in the direction of output power conversion devices, electrical components, etc., can solve the problems of large occupied space, difficult layout, reduced system efficiency, etc., to achieve the effect of rapid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

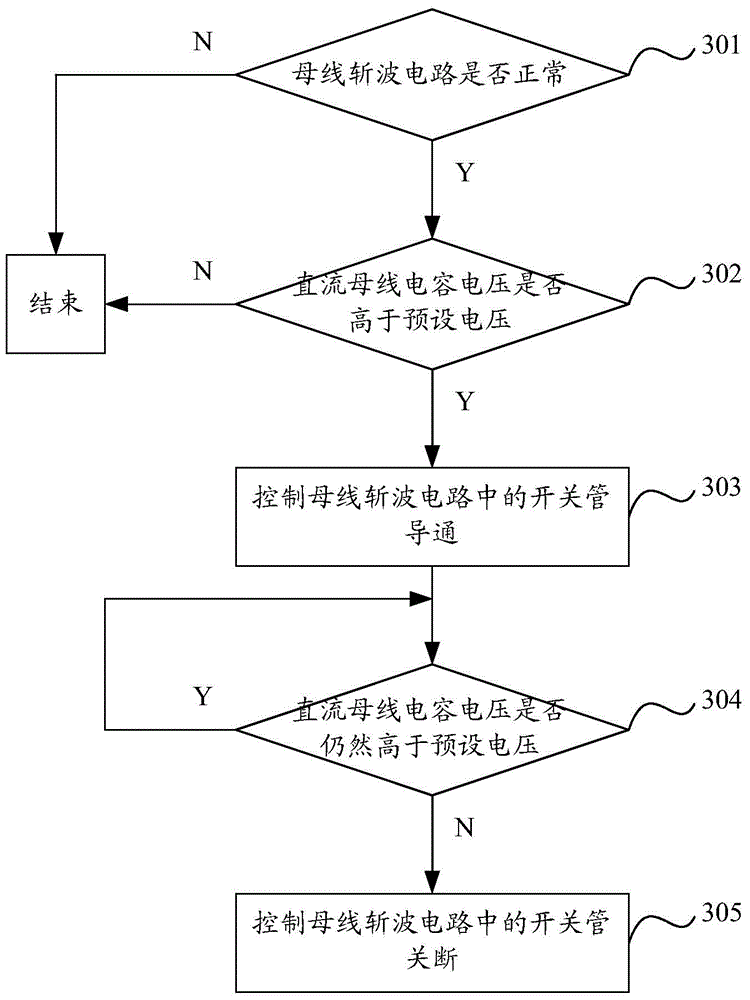

[0034] In Embodiment 1 of the present invention, the three-phase bridge type power electronic conversion system only has a bus chopper circuit, and only uses the bus chopper circuit to discharge the DC bus capacitor voltage.

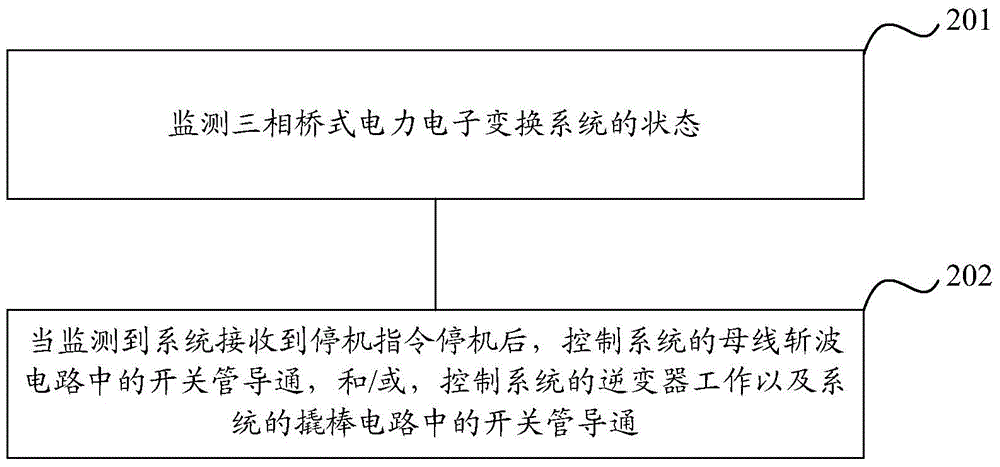

[0035] When the system receives the stop command to stop, execute the following process to realize the discharge of the DC bus capacitor voltage, such as image 3 shown, including:

[0036] Step 301, judging whether the bus chopper circuit of the system is normal.

[0037] When it is determined that the bus chopper circuit of the system is normal, continue to execute the following steps and enter step 302; when it is determined that the bus chopper circuit of the system is abnormal, the process ends.

[0038]In the prior art, there are many methods for judging whether the bus chopper circuit is normal, and any one of the prior art can be used as the specific implementation scheme of this step, and the following method provided by the embodiment of the p...

Embodiment 2

[0059] In Embodiment 2 of the present invention, the three-phase bridge type power electronic conversion system only has a crowbar circuit, and only the crowbar circuit is used to discharge the DC bus capacitor voltage.

[0060] When the system receives the stop command to stop, execute the following process to realize the discharge of the DC bus capacitor voltage, such as Figure 4 shown, including:

[0061] Step 401, judging whether the crowbar circuit of the system is normal.

[0062] When it is determined that the crowbar circuit of the system is normal, continue to perform the following steps, and enter step 402; when it is determined that the crowbar circuit of the system is abnormal, the process ends.

[0063] In the prior art, there are many methods for judging whether the crowbar circuit is normal, and any one of the prior art can be used as the specific implementation scheme of this step, and the following method provided by the embodiment of the present invention c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com