A method for making a standard plate for grayscale detection and comparison of heliostat areas

A manufacturing method and heliostat technology, applied in the preparation of test samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

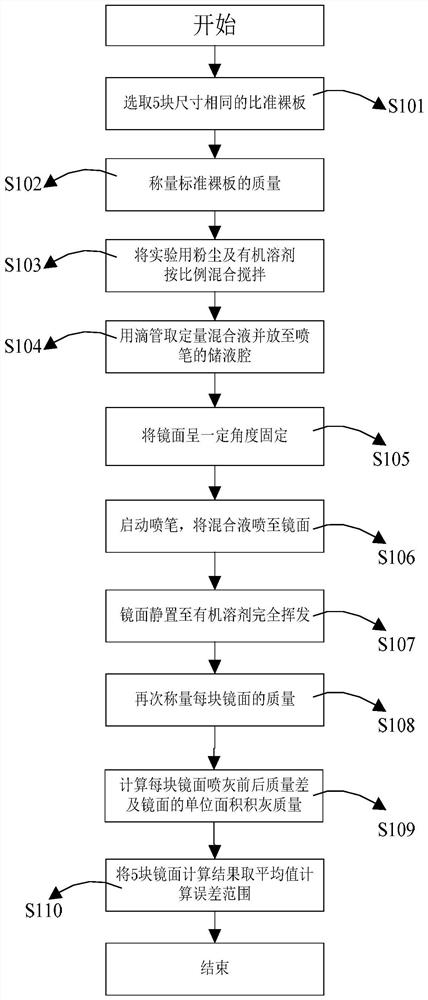

[0040] The present invention will be further described below in conjunction with drawings and embodiments.

[0041] Concrete embodiment of the present invention and its implementation process are as follows:

[0042] Step S101, preparing a plurality of standard bare boards with the same size;

[0043] One side surface of the standard bare board is a mirror surface, and the standard bare board is divided into five dust accumulation levels according to the gray scale of the heliostat mirror area, and 5 standard bare boards are prepared for each level, and the size of each standard bare board Similarly, the five dust accumulation levels are:

[0044] Level V represents severe dust accumulation, that is, the amount of dust on the surface of the mirror reaches saturation, and the dust can no longer fall to the mirror;

[0045]Grade IV means moderate dust accumulation, that is, the mass of dust per unit area on the mirror surface is half of Grade V;

[0046] Class III means gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com