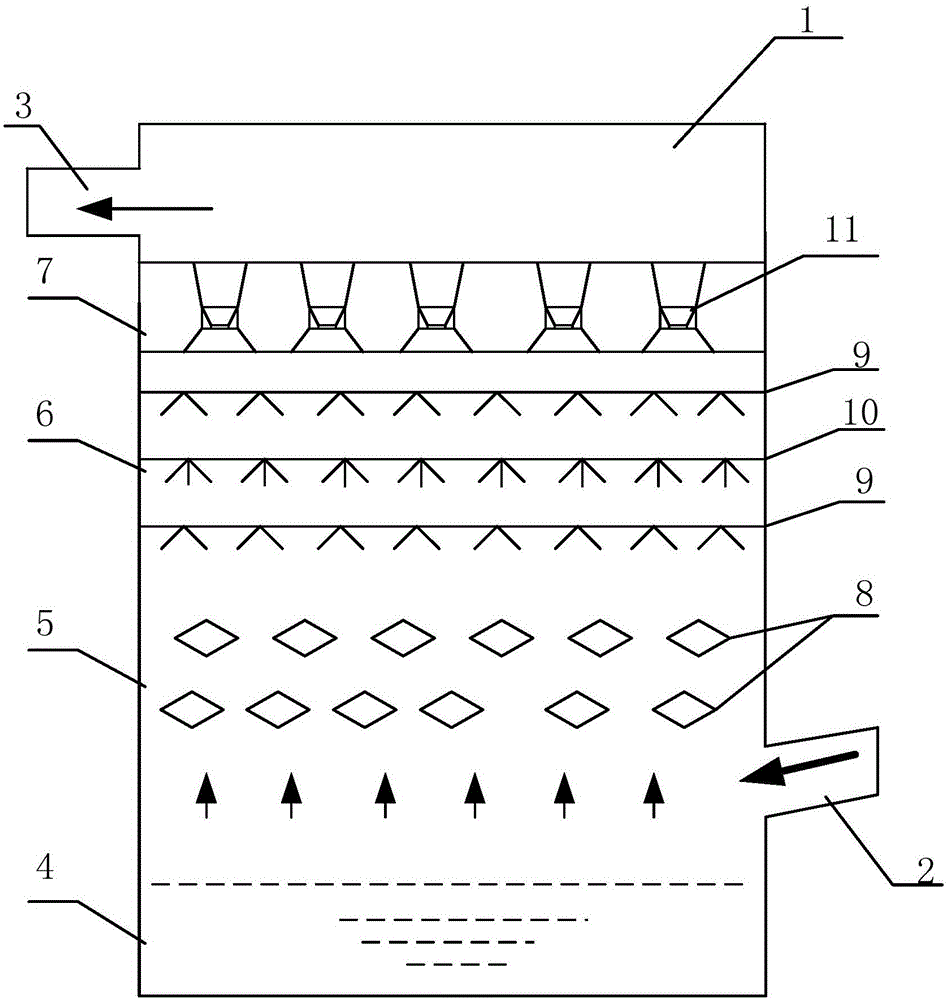

Efficient desulphurization and dust removal device

A high-efficiency technology for desulfurization and dust removal, applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low gas-liquid mass transfer efficiency between flue gas and slurry, difficulty in achieving high-efficiency desulfurization, and high investment cost. Avoiding gypsum rain, improving flue gas escape, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

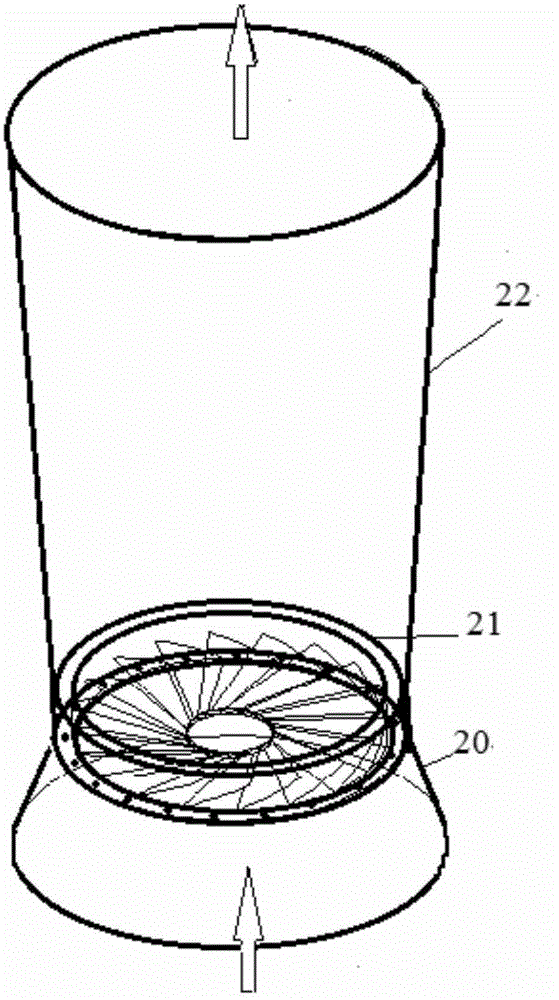

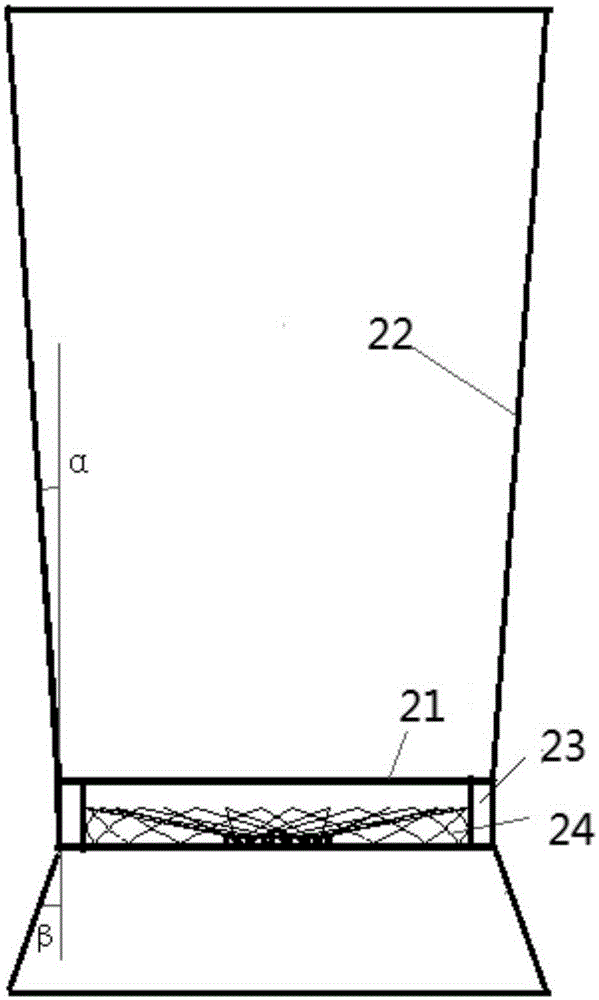

Embodiment example

[0035] The inlet tapered section is a frustum-shaped structure with a vertex angle range of 15-25°. The diameter of the inlet when the flue gas flows through this section is larger than the exit diameter of the flue gas flow through this section; the throat swirl section is a cylindrical structure, and the flue gas The diameter of the inlet when the gas flows through this section is equal to the outlet diameter when the smoke flows through this section. The central plate in the swirl element is a solid plate, and the ratio of the diameter of the swirl element to the swirl element is 0.2 to 0.4. The number of swirl blades There are 18 pieces, and the radial angle is -10~-20°, and the elevation angle is 20~30°; the gradual expansion section of the outlet is a rounded frustum-shaped structure, and the apex angle ranges from 2 to 8°. When the flue gas flows through this section The inlet diameter is smaller than the outlet diameter for flue gas flow through the section. In additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com