Fluidized bed type jet milling and modifying system and application thereof

A jet pulverization and fluidized bed technology, applied in chemical instruments and methods, chemical/physical processes, methods of granulating raw materials, etc. Pulverized fracture minimum stress reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further elaborated and illustrated below in conjunction with the embodiments of the present invention.

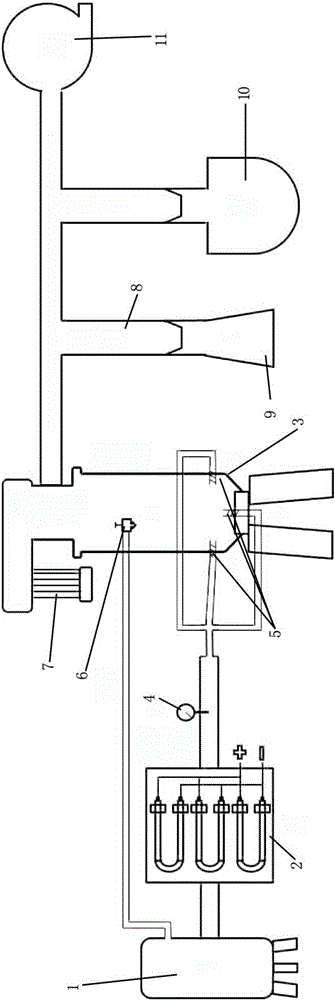

[0052] a kind of like figure 1 The shown fluidized bed airflow milling modification system comprises an air compressor 1, airflow milling and classifying device 3, cyclone separator 8, bag collector 10 and induced draft fan 11 connected in series in sequence, and is characterized in that the air A heater 2 is also connected in series between the press 1 and the jet crushing and classifying device 3; the jet crushing and classifying device 3 includes a crushing chamber, a classifying wheel 7 and a supersonic nozzle 5, and the side wall of the crushing chamber has a hole in the middle Atomizing nozzle 6 is installed, and described atomizing nozzle 6 is connected with air compressor 1 by pipeline, and described supersonic nozzle 5 is installed in the position near the bottom of pulverizing chamber, and described classification wheel 7 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com