Classification and sorting production line for abs, pp plastic chips or granules

A plastic fragment and production line technology, applied in the direction of solid separation, etc., can solve the problems of large price difference and low economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the drawings and specific embodiments:

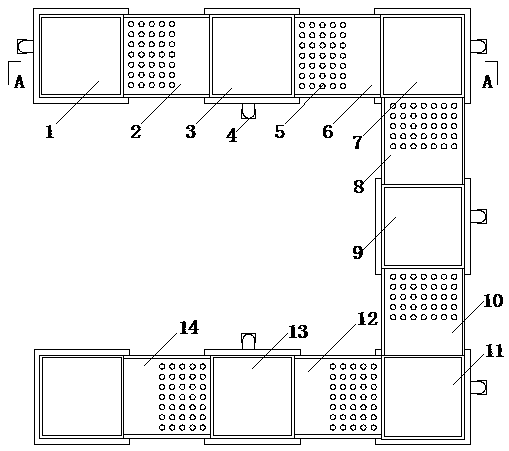

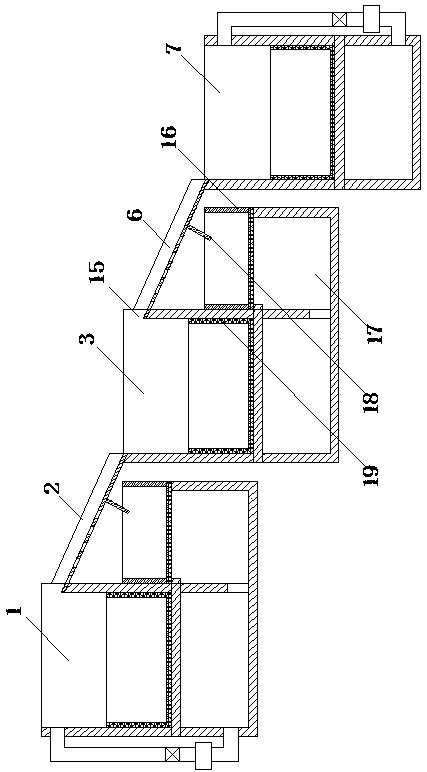

[0027] Such as figure 1 , figure 2 As shown, the classification and sorting production line of ABS, PP plastic fragments or particles of the present invention includes an ABS sorting device and a PP guide groove 8. The ABS sorting device includes an ABS sedimentation tank 3, an ABS circulation tank 17, and a sixth pressure pump 4. . The top of the ABS sedimentation tank 3 is open and is provided with an outflow port 15 lower than the open opening. The ABS circulation tank 17 is placed under the ABS deposition tank 3. The inlet of the sixth pressure pump 4 is in communication with the ABS circulation tank 17, and the outlet is in communication with the ABS deposition tank 3. The ABS sedimentation tank 3 and the ABS circulation tank 17 are respectively used to contain sodium chloride solution with a concentration of 20%-21.5%. The inlet end of the PP guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com