Cold press molding process for carrier body

A technology of cold forming and crafting, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., and can solve the problems of low product strength, flat forming, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

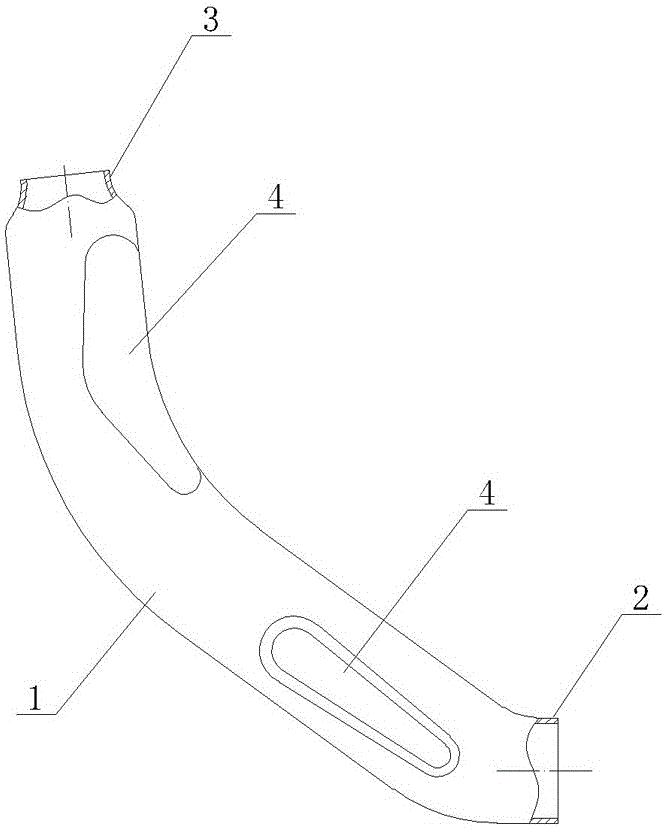

[0016] Such as figure 1 As shown, the bracket body 1 is formed by cold pressing of seamless steel pipe, the middle is designed as a bent pipe, the upper head has a constriction 3, the lower head has a narrowing 2, and there are many local flattened parts 4 on the pipe wall.

[0017] Such as Figure 1-6 As shown, the cold press forming process of the bracket body of the present invention comprises the following process steps: a. fixed-length blanking of seamless steel pipes (see figure 2 ); b. The diameter of the seamless steel pipe is reduced at one end (see image 3 ); c. Elbow (see Figure 4 ); d. One end of the seamless steel pipe shrinks (see Figure 5 ); e. In the forming mold, the wall of the seamless steel pipe is partially flattened (see figure 1 , Figure 6 ), the seamless steel pipe is filled with steel balls 11 when flattened and formed, and the two ends are movable to block, and the diameter of the steel balls 11 is 5mm.

[0018] Such as Figure 6 As shown,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com