Stacking-type combined electrode for electrosparking of micro inner grooves of slow wave structure and manufacturing method of stacking-type combined electrode

A slow-wave structure, combined electrode technology, applied in electrode manufacturing, electric processing equipment, metal processing equipment and other directions, can solve the problem that the overall electrode is difficult to meet the requirements of precise processing, high precision requirements, complex structure, etc., to ensure the shape and The effect of dimensional accuracy, high precision, and ease of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

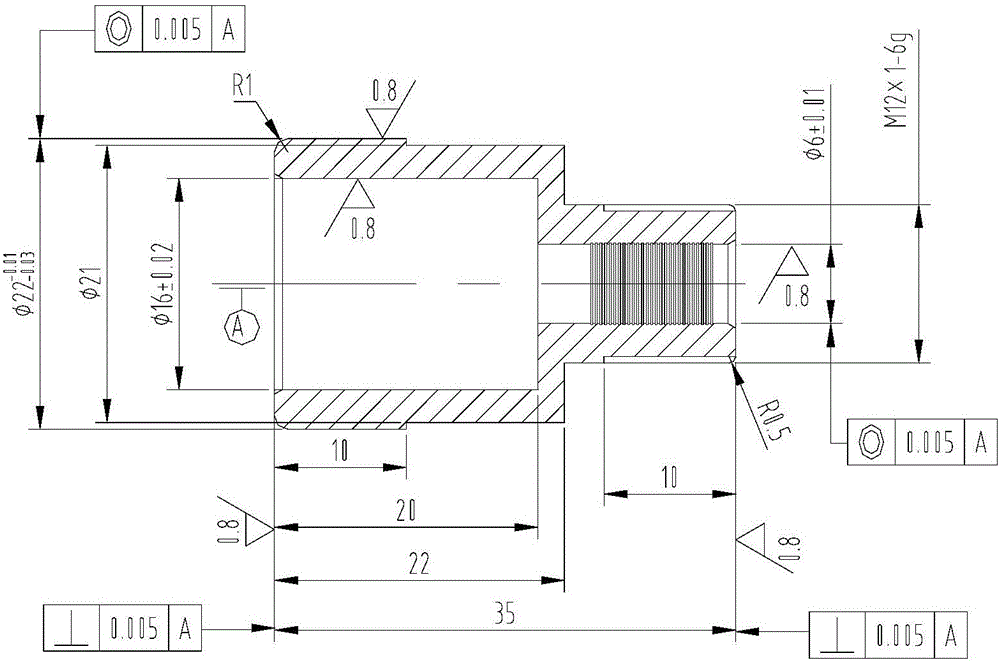

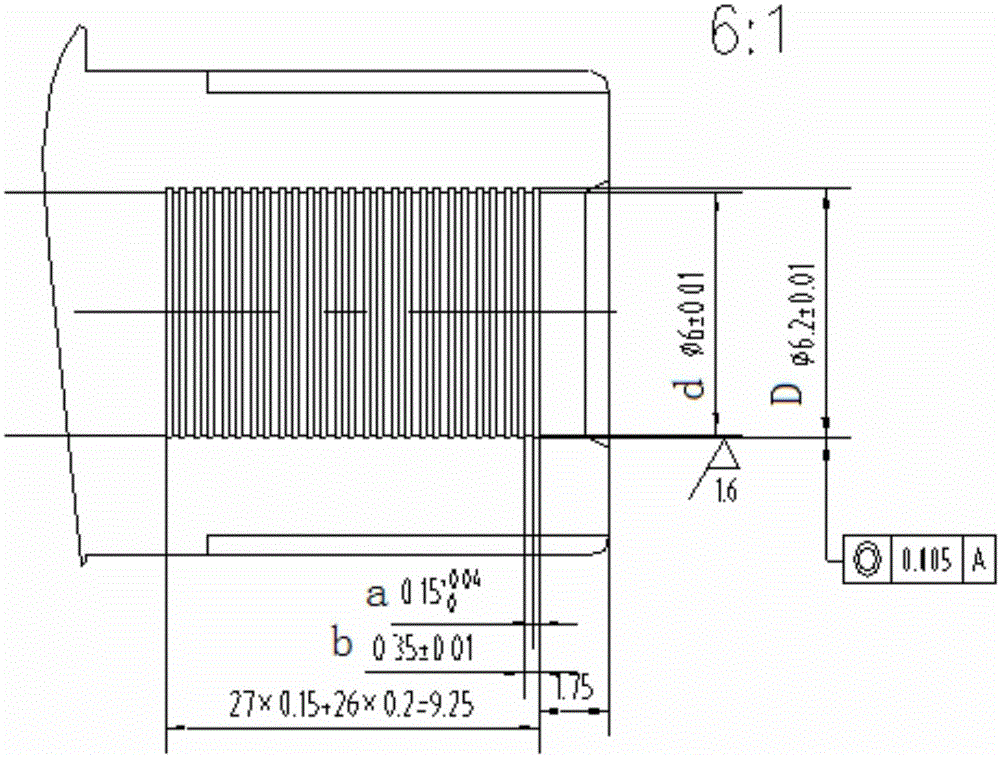

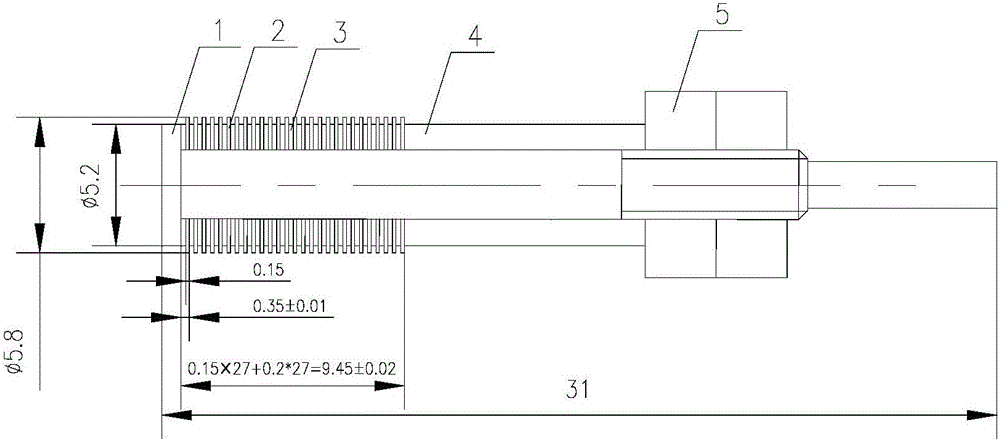

[0044] Such as Figure 3 to Figure 8 Shown is a stacked combined electrode for electric discharge machining of a slow-wave structure fine inner groove provided by the present invention. The electrode sheet is a copper disc 3 made of copper. On the positioning mandrel 1, the round copper sheet 2 with larger electrode diameter and the gasket 3 with smaller diameter are sleeved at intervals; the positioning mandrel 1 is provided with an axial positioning structure, so that the round copper sheet 2 and the gasket 3 Locate on mandrel 1.

[0045] Gasket 3 and electrode round copper sheet 2 can be made of the same material. The positioning mandrel 1 can be made of modulated 45 steel.

[0046]The axial positioning structure in this embodiment is: on both sides of the shaft section where the round copper sheet 2 and the gasket 3 are sleeved, one side of the shaft section with a larger diameter forms a positioning shoulder, and the shaft section with a larger diameter The diameter i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com