Automatic slurry conveying device used for high-altitude in building room and using method thereof

A technology of automatic conveying device and slurry, applied in the directions of liquid distribution, conveying or transfer device, distribution device, transportation and packaging, etc., can solve the problem of inconvenience of slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] This embodiment provides an automatic slurry conveying device for high-place construction in a building, the automatic slurry conveying device includes a storage tank, a power mechanism, and a discharge mechanism, and the storage tank and the discharge mechanism They are connected by connecting pipes, and the power mechanism is used to provide the power for conveying slurry to the discharging mechanism, and the discharging mechanism is provided with a discharging control switch for controlling the conveying of slurry.

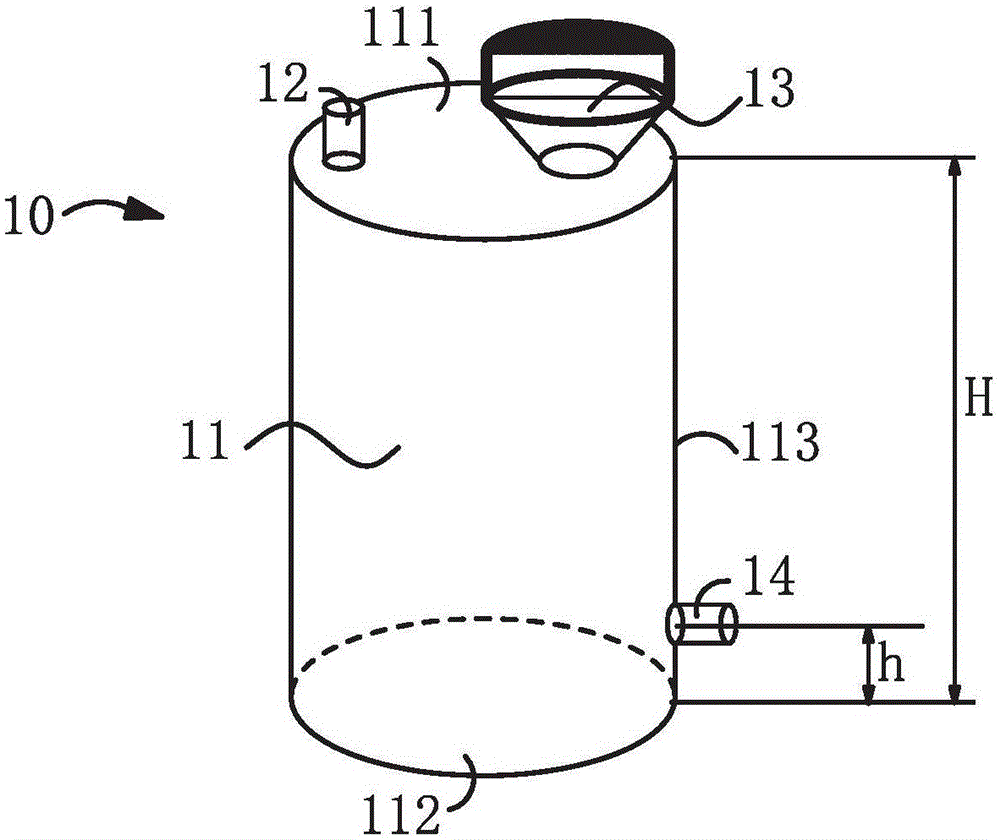

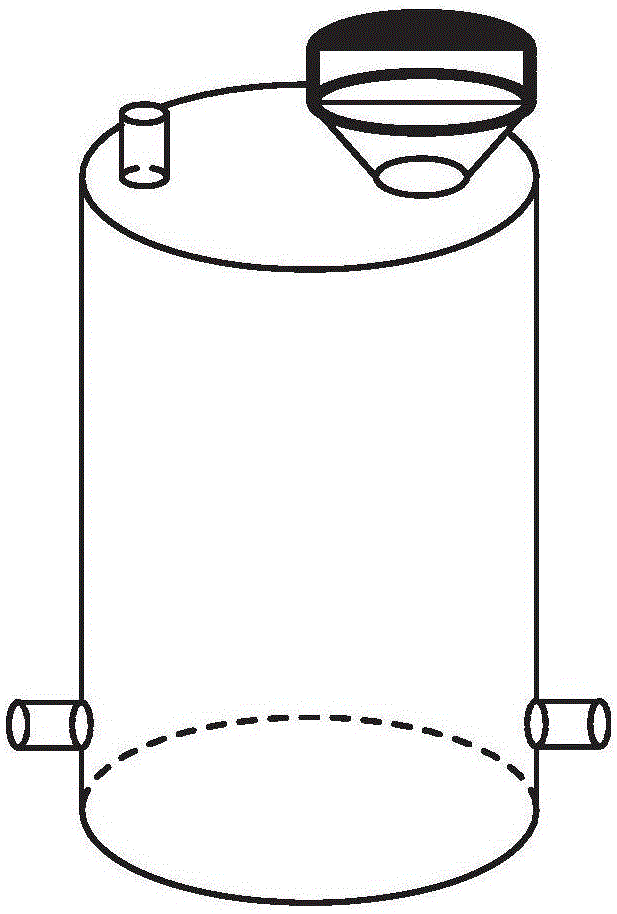

[0084] Wherein, the storage tank includes a tank body for holding the slurry, the top of the tank body is provided with an air inlet and a feeding part, the side wall of the tank body is provided with a discharge port, and the discharge mechanism includes A discharge part and a holding part, the front end of the discharge part is a discharge port, the rear end is connected to the front end of the holding part, and the rear end of the holding part is conne...

Embodiment 2

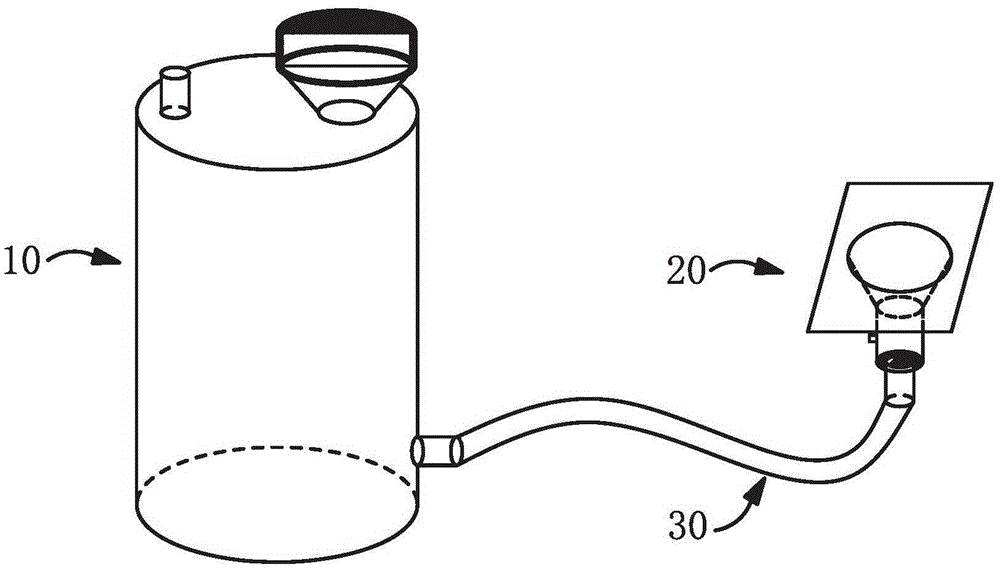

[0086] This embodiment provides an automatic slurry conveying device for construction at a high place in a building, such as the ceiling of a home or an office or a construction operation at a high place on a wall, such as figure 1 As shown, the conveying device includes a storage tank 10 , a power mechanism and a discharge mechanism 20 , and a connecting pipe 30 for connecting the storage tank 10 and the discharge mechanism 20 . Among them, the storage tank and the discharge mechanism are different independent structures. During construction, the two ends of the connecting pipe can be inserted into the storage tank and the discharge mechanism respectively to connect the two. Disconnect from the storage tank and the discharge mechanism respectively. It can be seen that the automatic slurry conveying device of the present invention is flexible in disassembly and assembly, and can be conveniently used in different construction occasions. In addition, the connecting pipe in this...

Embodiment 3

[0096] The difference between this embodiment and the second embodiment lies in the improvement of the discharge panel. Such as Image 6 As shown, in this embodiment, a side wall 26 is formed extending upward from the edge of the discharge panel 25 , and the discharge panel 25 and the side wall 26 jointly enclose to form an accommodating tank 40 capable of containing slurry.

[0097] Different slurries have different viscosities and corresponding fluidity. When the slurry with high viscosity and low fluidity is output, it first accumulates in the center of the discharge panel, and then slowly accumulates around due to the increase of the accumulation amount; while the slurry with low viscosity and high fluidity is discharged When it is difficult to accumulate and form, it is easier to flow around. If only the discharge panel is used to hold this type of slurry, the slurry is likely to overflow from the panel, but the improvement of this embodiment can just overcome this defe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com