Construction waste recycling treatment system

A construction waste, treatment system technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

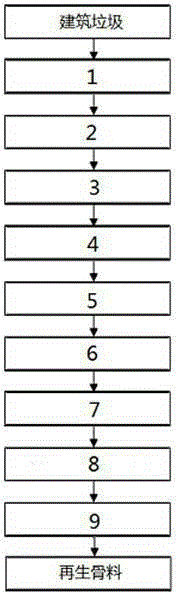

[0024] Such as figure 1 As shown, the construction waste recycling processing system of the present invention includes the following components connected in sequence by conveyor belts:

[0025] Storage bin (1): used to store different types of construction waste;

[0026] Pretreatment equipment (2): used to crush large pieces of construction waste;

[0027] Loading and unloading equipment (3): used for filling and loading and unloading pretreatment of broken large pieces of construction waste;

[0028] Primary screening equipment (4): used to remove impurities before primary crushing;

[0029] Primary crushing equipment (5): used for primary crushing of waste;

[0030] Electromagnetic separation equipment (6): used to separate iron;

[0031] Secondary screening equipment (7): used to separate aggregates with smaller particle sizes;

[0032] Secondary crushing equipment (8): used to crush aggregates into required particle sizes;

[0033] Tertiary Screening Equipment (9): ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com