Processing method of water transfer printing paper

A processing method and technology of printing paper, applied in the direction of papermaking, paper machine, paper coating, etc., can solve the problems of large stress difference, large printing deformation, unstable overprint performance of water transfer printing paper, etc., and achieve the effect of smoothing the internal stress of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0032] The processing method of the water transfer printing paper of the present embodiment, the steps include:

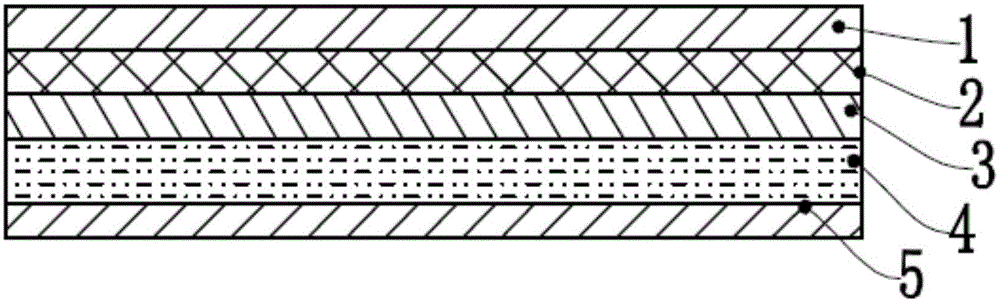

[0033] A. The base paper is unrolled, coated with a bottom coating on one side of the base paper, and dried;

[0034] B. Coating an intermediate coating on the surface of the bottom coating and drying;

[0035] C. Coating the surface coating on the surface of the intermediate coating and drying;

[0036] D. The other side of the steam spray base paper;

[0037] E. The other side of the base paper is coated with a back coating and dried;

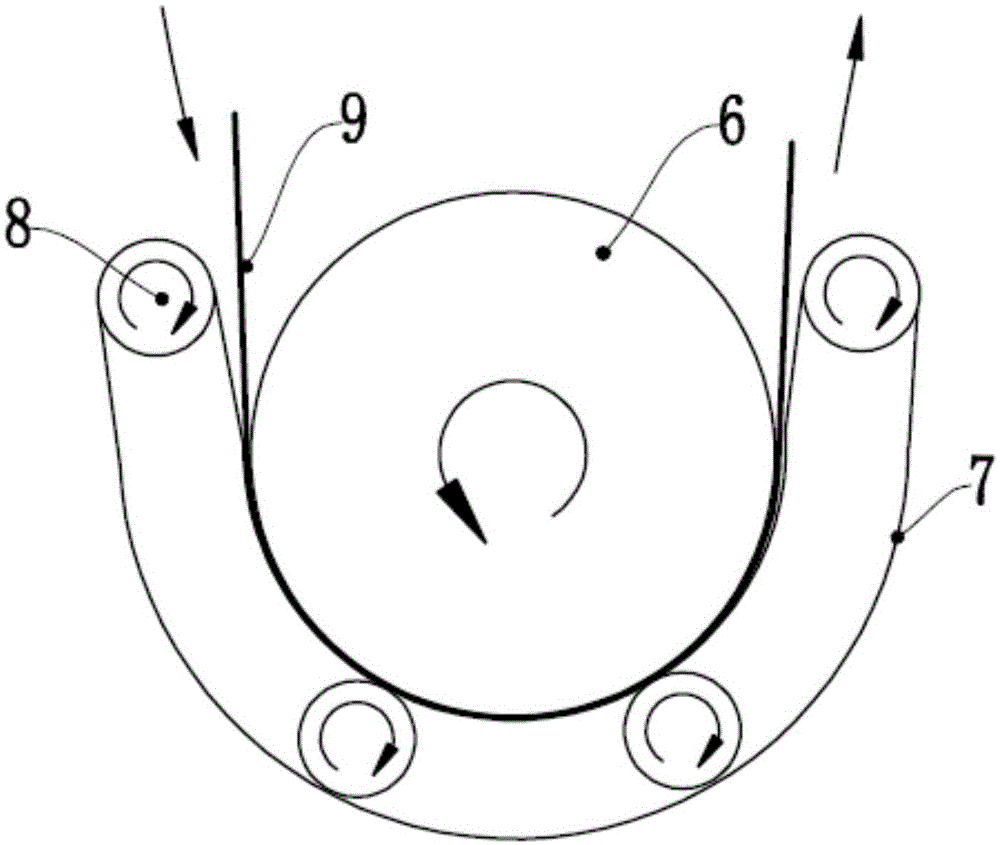

[0038] F. Adjust the state of the base paper by using a drying cylinder device;

[0039] G. Acquired products after winding, slitting and packaging.

[0040] Before the step E, a steam spray process (step D) is set, and the back of the water transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com