Shovel loader capable of weighing mixed materials automatically

A technology for automatic weighing and mixing of materials, applied in the field of buckets, which can solve the problems of single bucket function, inability to mix and stir materials, and weighing and proportioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

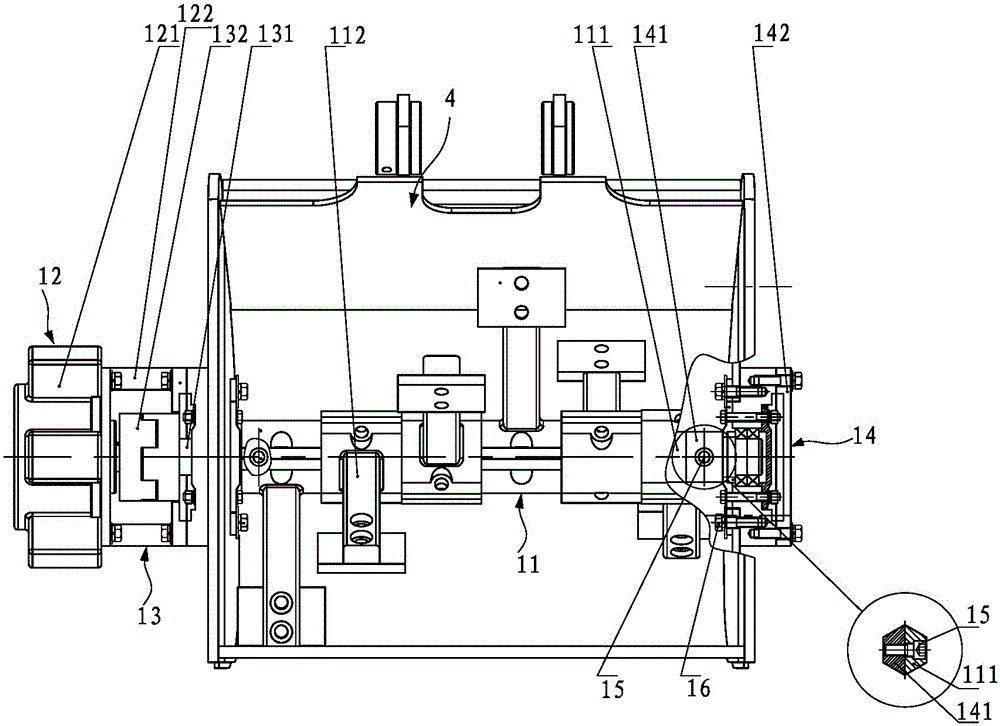

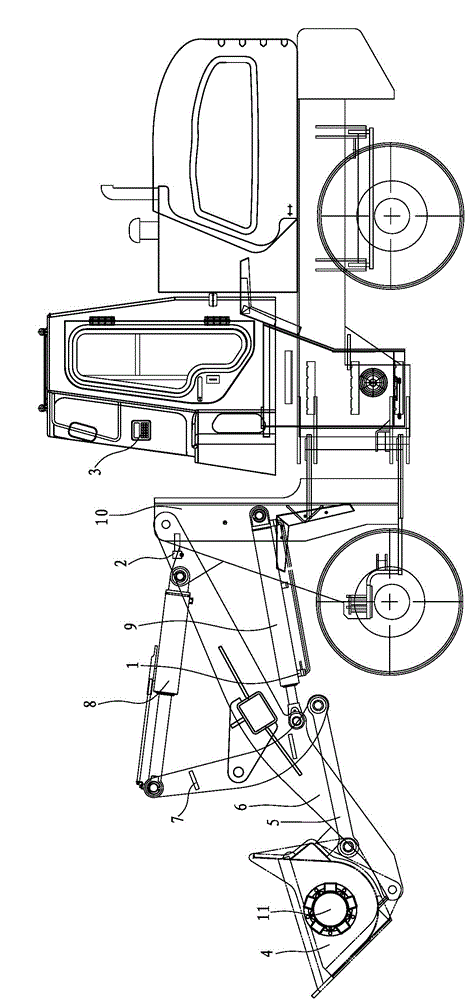

[0018] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0019] Such as figure 1 As shown, it is a bucket with the function of automatically weighing mixed materials disclosed by the present invention, including a bucket body 4, a rocker 7 that makes the bucket body 4 rotate, a boom 6 that makes the bucket body 4 rise, and The bucket cylinder 8 and the boom cylinder 9 that provide power for the rocker arm 7 and the boom 6 respectively, the bucket body 4 and the rocker arm 7 are connected by a tie rod 5, and the connection mode between each component is a pin connection. , also includes a stirring device detachably installed on the bucket body 4 and an automatic weighing system installed on the vehicle frame 10 and the boom 6 .

[0020] The automatic weighing system is composed of a data acquisition unit 1, a position recognition unit 2, and a display processing unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com