Bag-type air-pressure tank used for domestic drinking water pressurization equipment

A technology for drinking water and pressurizing equipment, applied in the field of bladder-type air pressure tanks, can solve the problems of secondary water pollution and microorganisms causing water corruption and deterioration, and achieve the effect of ensuring water quality safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

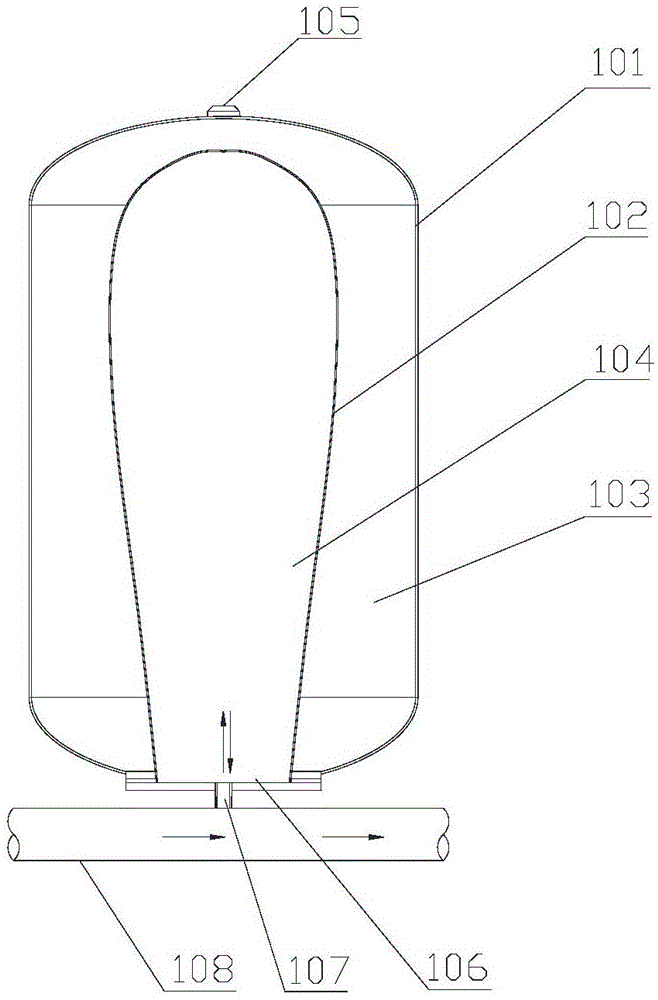

[0052] Example 1, see figure 2 .

[0053] This embodiment provides a bladder-type air tank used for domestic drinking water pressurization equipment, including a tank body 101, a rubber air bag 102 and a water inlet and outlet structure.

[0054] The rubber air bag 102 is arranged in the tank body 101 and divides the inside of the tank body 101 into an air chamber 103 and a water chamber 104 . The air chamber 103 is located between the outer wall of the rubber air bag 102 and the inner wall of the tank body 101 , and the water chamber 104 is located in the rubber air bag 102 . The tank body 101 is cylindrical, and the axis line of the tank body 101 is arranged vertically. The top and bottom of the tank body 101 are the upper head and the lower head respectively, and the upper head and the lower head are respectively provided with gas filling ports. 105 and the water inlet and outlet 106, the gas filling port 105 and the water inlet and outlet 106 communicate with the air ch...

Embodiment 2

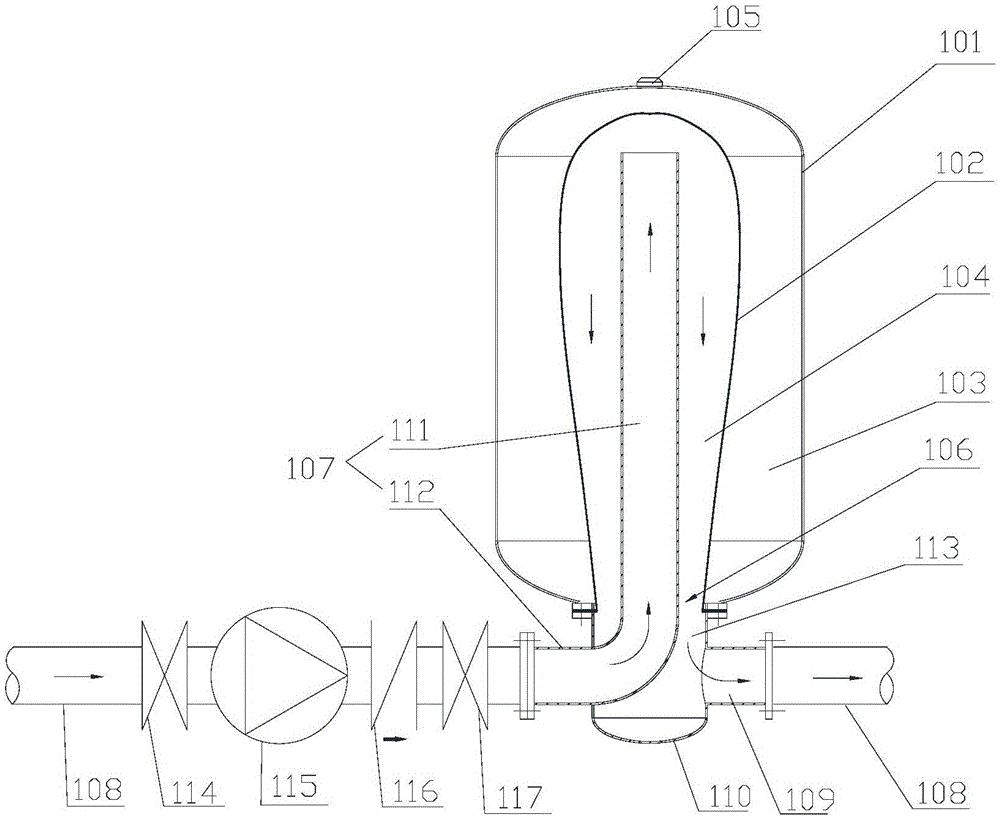

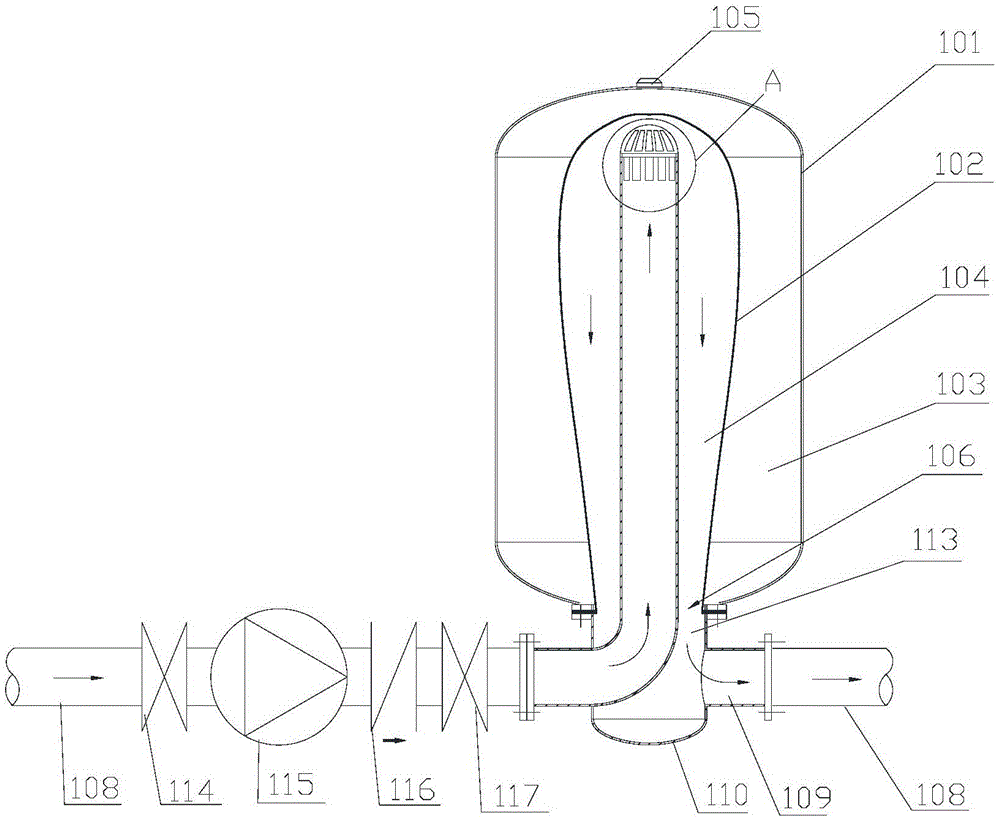

[0064] Example 2, see Figure 3 ~ Figure 5 .

[0065] This embodiment provides a bladder-type air tank for domestic water delivery pipelines. Compared with Embodiment 1, this embodiment only improves the water inlet pipe 107. For other parts not mentioned in this embodiment, please refer to Example 1.

[0066] In this embodiment, the water outlet end of the water inlet pipe 107 is connected with a water outlet cover 118 , and the middle part of the water outlet cover 118 protrudes away from the water inlet pipe 107 and forms an arc surface. The ratio of the raised height of the water outlet cover 118 to the radius of the water inlet pipe is 0.5˜2:1, preferably 1:1. A plurality of first water outlet holes 119 are disposed on the water outlet cover 118 , and a plurality of first water outlet holes 116 are arranged along a circumferential direction of the water outlet cover 118 . The water outlet end of the water inlet pipe 107 is provided with a plurality of second water outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com